Your Guide to EV Charger Installation Requirements

For installers, developers, and homeowners, understanding the core EV charger installation requirements is the critical first step to a safe, compliant, and cost-effective project. This guide delivers a no-nonsense breakdown of the essential electrical system assessments, NEC code compliance, and equipment choices you need to master. We'll cover the real-world decision points for load calculations, permitting, and site selection to ensure your project succeeds, whether it's a single home charger or a multi-unit commercial deployment.

Assessing Your Electrical System for EV Charging

The first question any installer or property owner must answer is whether the current electrical service can support an EV charger. This isn't about finding an empty breaker slot; it requires a formal load calculation as defined by the National Electrical Code (NEC) to prevent system overloads and fire hazards. A Level 2 EV charger is a "continuous load," placing a heavy, sustained strain on the system for hours at a time.

This calculation inventories the property’s total power demand—HVAC, appliances, lighting—to determine the existing load and available spare capacity. This is a non-negotiable step for a code-compliant installation.

Critical Mistake to Avoid: Assuming physical space in a breaker box equals electrical capacity. A full 100A panel, common in older homes, almost never has the capacity for a 40A or 50A EV charger, even with open slots. The load calculation is the only way to prove capacity.

Identifying Potential System Overloads

A panel already near its limit is a major red flag for any EV charging project. Telltale signs of an overloaded or outdated system are often visible before running the numbers:

- Frequent Breaker Trips: A clear indicator the panel is already struggling to meet existing demand.

- A Full Breaker Box: No physical space for a new double-pole breaker often signals an older, smaller service (e.g., 100A) that lacks capacity.

- Flickering Lights: A classic symptom of a system under strain, especially when large appliances like an AC unit turn on.

A dedicated circuit is a mandatory requirement for any Level 2 charger. It isolates the charger, guaranteeing consistent power and preventing it from tripping circuits shared with other devices—a fundamental safety and performance rule.

The Need for an Upgrade

If the load calculation confirms insufficient capacity, an electrical service upgrade is the only safe and legal path forward. Attempting to add a charger to a maxed-out panel is a severe safety hazard that will fail inspection. For a full breakdown of this process, see our guide on how to upgrade your electrical service.

This initial assessment is more critical than ever. With EV adoption accelerating, every new installation must be built on a solid electrical foundation. The U.S. market saw a 4.6% increase in total EV charging ports in Q1 2024 alone, highlighting the rapid infrastructure expansion that starts at the panel.

Initial Site Electrical Assessment Checklist

This checklist provides a practical overview of the essential electrical checks required before any EV charger installation begins.

| Checklist Item | Residential (Single-Family) | Commercial (Small Business) | Key Consideration |

|---|---|---|---|

| Panel Capacity | Typically 100A, 125A, or 200A | 200A, 400A, or higher (3-phase) | Verify the main breaker rating. 200A service is the modern standard for homes integrating EV charging. |

| Load Calculation | Perform NEC Article 220 calculation | Perform NEC Article 220 calculation | For Installers: Must account for the new continuous EV charger load at 125% of its rating. This is a common point of failure in inspections. |

| Available Breaker Space | Need 2 adjacent slots for a 240V breaker | Need 2 or 3 adjacent slots depending on voltage | Physical space does not equal electrical capacity. |

| Dedicated Circuit | Required for Level 2 charging | Required for all dedicated EVSE | Ensures safety and prevents nuisance tripping of other circuits. Non-negotiable per NEC. |

| System Voltage | 240V (split-phase) | 208V/240V/480V (often 3-phase) | The charger's voltage rating must match the building's electrical service. Mismatching can damage the equipment. |

| Grounding and Bonding | Verify proper grounding at panel | Verify proper grounding and bonding | Essential for safety and the proper function of the charger's required GFCI protection. |

Completing these checks upfront prevents costly change orders, project delays, and failed inspections.

Navigating NEC Compliance and Local Permitting

With electrical capacity confirmed, the next phase is ensuring the installation is fully compliant with national and local codes. This is a legal requirement designed to protect people and property. The process involves satisfying two key authorities: the National Electrical Code (NEC) and the local permitting office, or Authority Having Jurisdiction (AHJ).

The NEC Article 625 Playbook

For EV chargers, NEC Article 625 (Electric Vehicle Power Transfer Systems) is the installer's primary reference, outlining the minimum safety standards for all U.S. installations.

Key mandatory requirements include:

- GFCI Protection: All charging outlets or hardwired units must have Ground-Fault Circuit-Interrupter protection to prevent electrical shock.

- Breaker and Wire Sizing: The circuit breaker and wire must be sized to handle 125% of the charger's maximum continuous load. This safety margin prevents overheating during long charging sessions.

- A Clear Disconnect: For chargers rated over 60 amps or more than 150 volts to ground, the NEC generally requires a dedicated, visible, and accessible disconnect switch near the unit.

Pro Tip for Installers: Always verify which NEC edition your local jurisdiction has adopted. A municipality may be on the 2017 code while the state follows 2020 or 2023. This discrepancy can significantly alter requirements for GFCI, disconnects, and load management systems.

Working with Your Local Gatekeeper: The AHJ

The Authority Having Jurisdiction (AHJ)—typically the city or county building department—has the final say on your project. They issue the required permits and perform the final inspection.

For any Level 2 charger installation, a permit is mandatory. The application package typically requires:

- A site plan showing the charger location.

- The electrical load calculation proving panel capacity.

- A one-line electrical diagram of the new circuit.

- The manufacturer's specification sheets for the EVSE (Electric Vehicle Supply Equipment).

For commercial projects, requirements expand significantly. Americans with Disabilities Act (ADA) standards dictate the number of accessible spaces, charger mounting height, and clear pathways. Failing to meet these standards will result in a failed inspection and costly rework.

While the NEC sets the U.S. standard, other countries have different mandates. For example, see the regulations mandating EV charging installation in new UK homes for a contrasting approach. Successfully navigating both national code and local AHJ requirements is what defines a professional, safe, and legal installation.

Choosing the Right Charger and Installation Location

Selecting the right charger and its location are the two most impactful decisions in the installation process. These choices dictate project cost, complexity, and daily usability.

The EV charging market is projected to grow from USD 28.47 billion in 2025 to USD 76.31 billion by 2032, fueled by networks from major brands like Tesla, Rivian, and Electrify America. For a deeper analysis of this growth, you can explore detailed EV charging statistics.

Comparing Charger Levels

Understanding the different charger levels is crucial, as each has specific electrical requirements and use cases. This choice is foundational to meeting your project's ev charger installation requirements.

EV Charger Level Comparison and Requirements

This table breaks down the three main charger levels, their power needs, and ideal applications.

| Charger Level | Voltage Requirement | Amperage (Typical) | Charging Speed (Miles/Hour) | Best For |

|---|---|---|---|---|

| Level 1 | Standard 120V | 12A - 16A | 3 - 5 | Homeowners (emergency backup), PHEVs with small batteries. Not a primary solution. |

| Level 2 | Dedicated 240V | 30A - 50A | 25 - 40 | Installers/Homeowners (daily charging), Developers/EPCs (workplace, MUD, retail). |

| DC Fast Charging | 480V (3-Phase) | 100A+ | 100 - 350+ | Developers/EPCs (public corridors, fleet depots, commercial supercharging). |

Level 1 is a slow trickle charge. Level 2 is the standard for home and workplace charging. DC Fast Charging is a commercial-grade solution where rapid turnaround is essential.

Selecting the Optimal Installation Site

After choosing a charger level, the installation location must be determined based on safety, code compliance, and convenience.

For homeowners, the garage is the ideal location, offering weather protection and security. For any outdoor installation, a charger with a NEMA 3R or NEMA 4 rating is mandatory to protect against rain, dust, and other environmental factors.

Compliance Watchout: The distance from the electrical panel to the charger location directly impacts cost. Longer wire runs require thicker, more expensive wire to compensate for voltage drop, a factor that must be calculated per NEC guidelines.

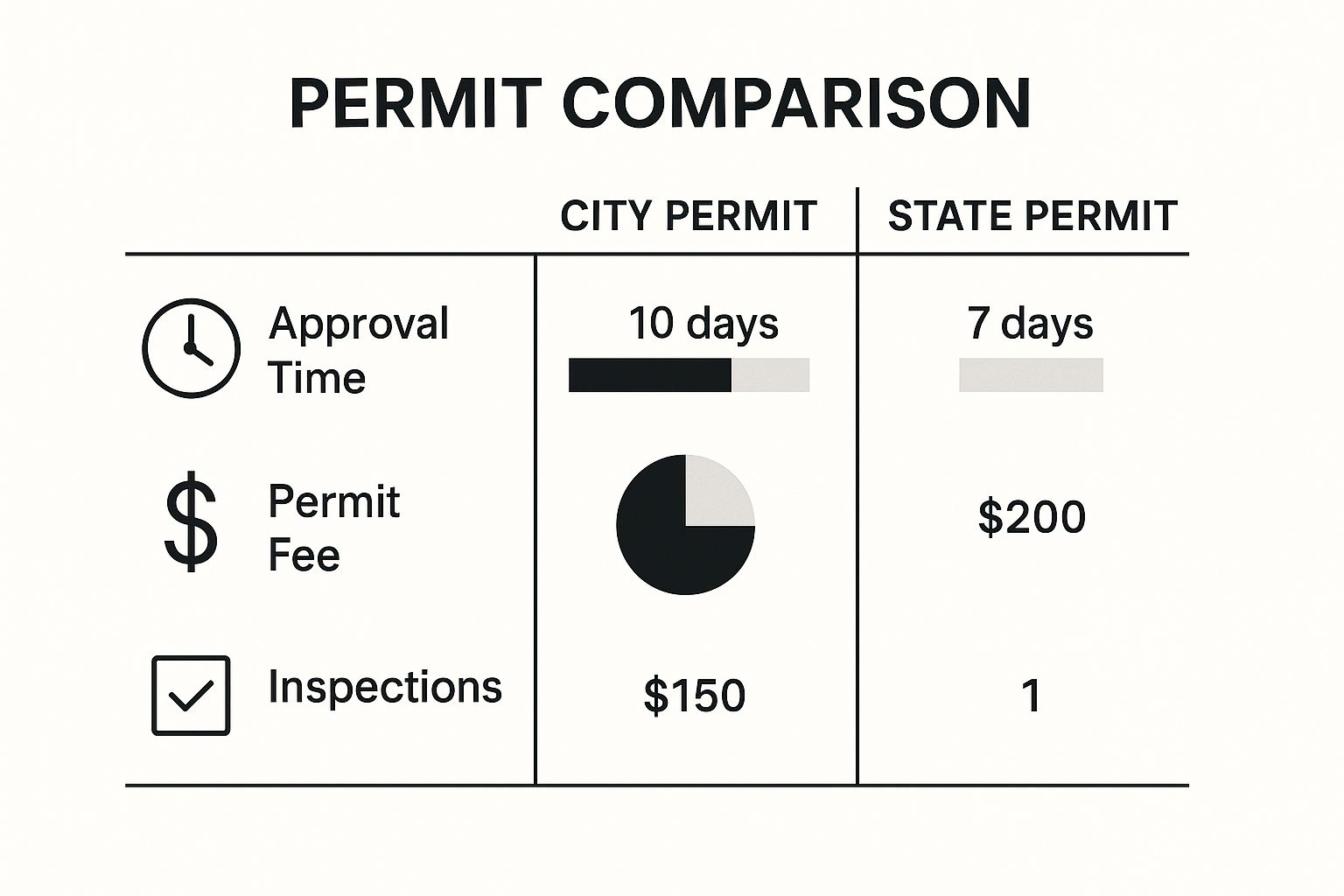

The image below illustrates the significant variation in permitting requirements between jurisdictions, which can affect project timelines and budgets.

Variations in permit fees and inspection counts underscore the importance of consulting with the local AHJ early in the planning process.

Proper cable management is also a safety requirement. A loose cord is a tripping hazard. A wall-mounted holster or retractable reel keeps the area safe and organized. In high-traffic areas like commercial lots, installing protective bollards is a smart, preventative measure against vehicle damage.

Key Requirements for Commercial and Public Installations

For developers, EPCs, and facility managers, deploying commercial EV charging stations introduces complex requirements beyond a simple home setup. These installations are public-facing assets that demand rigorous attention to accessibility, safety, and networked operations. Success hinges on balancing user experience with long-term operational costs and scalability.

Physical Site and Safety Demands

The physical layout and safety of public charging stations are governed by strict codes and practical considerations.

- ADA Compliance: This is a legal mandate, not a suggestion. The Americans with Disabilities Act dictates parking space dimensions, clear ground space, and charger mounting height to ensure accessibility for all users.

- Equipment Protection: In high-traffic parking lots, steel bollards or concrete wheel stops are essential to protect the charging equipment from vehicle impacts, preventing costly damage and downtime.

- Strategic Lighting: Well-lit charging areas are crucial for user safety and deterring vandalism, particularly for facilities operating 24/7.

For Fleet Managers: Efficient fleet operations depend on smart charging infrastructure. Our EV Fleet Management Tips provide strategies to maximize your charging investment from day one.

Networking and Smart Operations

Modern commercial chargers are networked assets that can generate revenue, provide valuable data, and be managed remotely. Skipping this connectivity leaves significant value on the table.

Smart chargers connect to a central software platform via Wi-Fi or cellular, unlocking key features:

- Payment Processing: Enable secure payment via credit card, RFID, or mobile apps.

- Usage Analytics: Track energy consumption, session duration, and peak usage times to optimize pricing and plan for future expansion.

- Remote Management: Troubleshoot issues, deploy software updates, and manage user access remotely, reducing operational costs.

This diagram from ADA.gov specifies the required dimensions for accessible charging stations—details that are critical for site design and compliance.

The requirements for clear floor space and accessible reach range directly influence site layout and equipment selection.

Scalability and Energy Management

A common mistake is designing an installation only for current needs. A forward-thinking plan anticipates growth by installing sufficient conduit and sizing electrical infrastructure to accommodate future chargers. This "future-proofing" avoids expensive and disruptive trenching work later.

Furthermore, integrating chargers with a building's Energy Management System (EMS) is critical for controlling costs. An EMS can mitigate high demand charges from utilities by automatically reducing charging speeds during peak energy usage hours, directly impacting the facility's operational budget.

Making the Most of Incentives and Regional Rules

Federal, state, and utility incentives can significantly reduce the cost of an EV charger installation, but they come with specific technical and performance requirements. For installers and developers, designing a project to meet these rules from the outset is essential for securing funding.

These programs, from tax credits to rebates, often require specific hardware. For example, many utility programs will only fund networked "smart" chargers capable of demand-response communication, allowing them to manage grid load during peak hours.

Decoding Program-Specific Requirements

Before purchasing any equipment, project stakeholders must research available incentives and their detailed requirements.

Common stipulations include:

- Hardware Certification: Mandates for chargers to be ENERGY STAR certified or listed on a pre-approved equipment roster.

- Networking Capability: Requirements for Open Charge Point Protocol (OCPP) compliance for public or commercial chargers to ensure interoperability for data and payment processing.

- Installation by Certified Pros: Many programs require installation by an electrician with a specific credential, such as the Electric Vehicle Infrastructure Training Program (EVITP) certification.

Critical Mistake to Avoid: Buying the charger before checking incentive requirements. This backward approach frequently leads to disqualification. Project design and equipment selection must align with program rules from the start to maximize financial benefits.

A Look at State-Level Influence

State policies are a major driver of installation standards. California, a leader in EV adoption, offers a prime example. Its incentive programs have some of the strictest technical requirements, which has directly contributed to its robust charging network.

California now has over 178,549 public and shared private EV chargers, with 48% more charging ports than gasoline nozzles in the state. This growth demonstrates how regional rules effectively become the de facto ev charger installation requirements for any financially viable project.

Understanding the total EV charging station installation cost and how these incentives impact the final number is a crucial step in any project proposal. At Portlandia Electric Supply, we help you navigate these complex rules, ensuring your project is compliant and optimized to receive all available funding.

Common Questions About EV Charger Installation

Whether you are a homeowner, an installer, or a commercial developer, navigating the technical specifics of EV charging raises questions. Here are clear, direct answers to the most common inquiries.

Do I Need a Permit for a Home EV Charger?

Yes. For any Level 2 charger installation, a permit is required. Adding a 240-volt circuit constitutes major electrical work. A licensed electrician must pull this permit, which triggers a mandatory inspection to verify the installation meets all NEC and local safety codes. Skipping this step can void your homeowner's insurance, result in fines, and create a serious fire hazard.

What Is a Load Calculation and Why Is It Essential?

A load calculation is an electrical safety audit of a property. It is the mandatory first step in any professional EV charger installation. An electrician calculates the total power consumption of all existing appliances and systems to determine if the main electrical panel has enough spare capacity to safely handle the large, continuous load of an EV charger. This is an NEC requirement to prevent system overloads and electrical fires.

For Installers: A load calculation isn't optional or a "nice-to-have." It is the code-required proof that a system can handle the new load. Submitting this calculation with your permit application is standard practice and demonstrates due diligence to the AHJ.

What Are the Main Requirements for Outdoor Installations?

Outdoor installations require equipment specifically designed to withstand the elements.

- NEMA Rating: The charger must have a NEMA 3R, 4, or higher rating, certifying its enclosure is protected against rain, snow, and dust.

- Weather-Rated Wiring: All exterior cabling must be rated for outdoor/wet conditions and run through a protective conduit to prevent physical damage.

- Protected Connections: Outlets and connection points must be weather-resistant and feature "in-use" covers that maintain a seal even when a vehicle is plugged in.

Can I Install a DC Fast Charger at My House?

For 99.9% of residential properties, the answer is a definitive no. DC Fast Chargers (DCFC) require three-phase, 480-volt electrical service, which is standard in commercial and industrial facilities, not homes. Residential properties use 240-volt, single-phase power. Upgrading a home's service to support a DCFC would be prohibitively expensive, easily costing tens of thousands of dollars. A Level 2 charger is the most powerful and practical solution for home use.

At Portlandia Electric Supply, our team provides the certified equipment and technical expertise to navigate every requirement, ensuring your project is safe, compliant, and ready for the future. Request a quote today and let our experts help you build your project right.