3 products

-

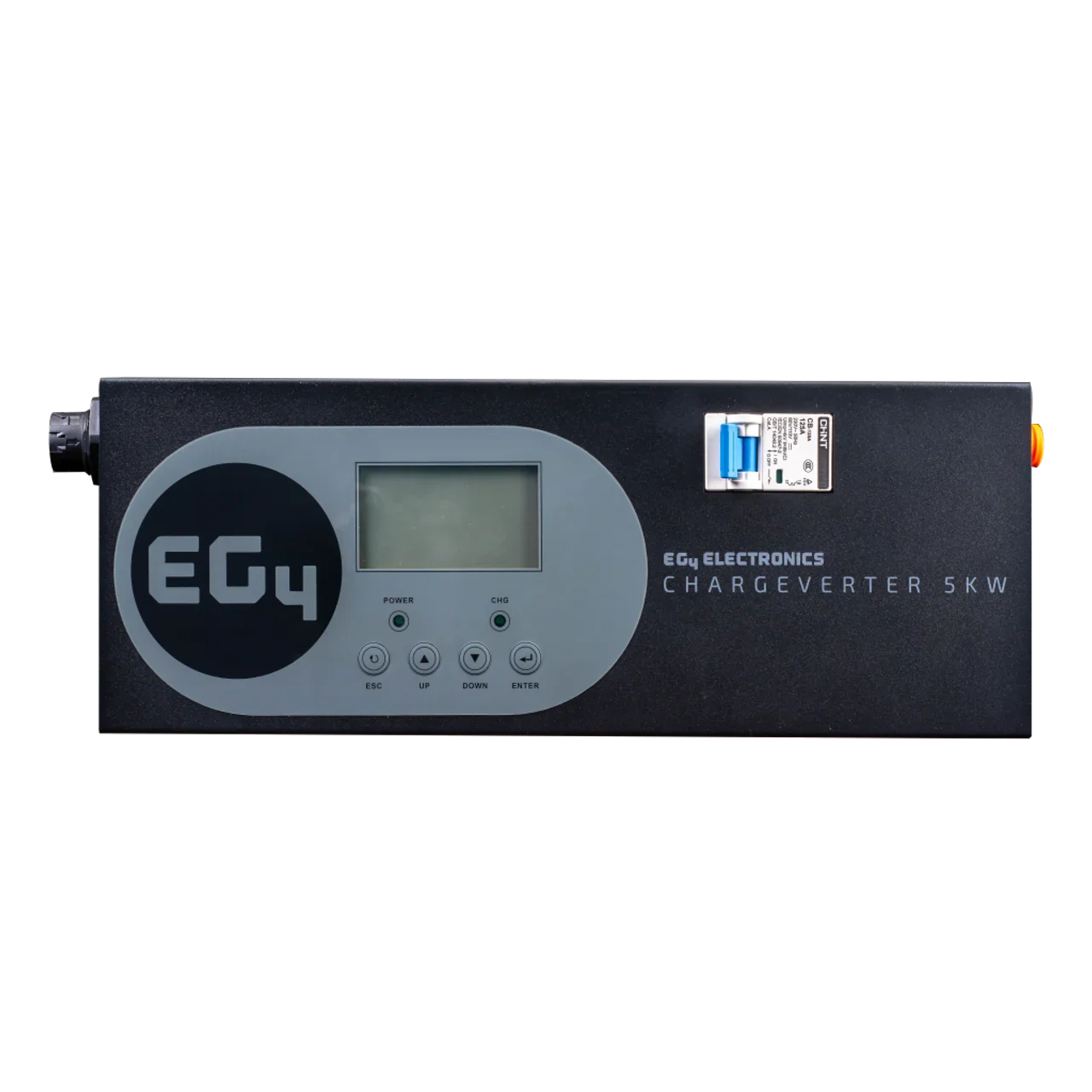

SKU: PES-PA-REC-0005MPN NOVendor:MidNite SolarRegular price $841.12 USDRegular priceUnit price per

-

SKU: PES-PA-REC-0016MPN NOVendor:MidNite SolarRegular price $1,850.00 USDRegular priceUnit price per

-

SKU: PES-PA-REC-0083MPN NOVendor:MidNite SolarRegular price $2,018.87 USDRegular priceUnit price per

-

Wind Energy Components play a crucial role in ensuring stable, efficient, and long-term renewable energy production, making them essential for anyone building, maintaining, or optimizing wind-powered systems. As demand for clean power continues to surge, the need for high-quality components becomes more important than ever. Whether you are involved in commercial wind farms, industrial-scale renewable installations, or advanced research applications, choosing the right parts directly impacts performance, safety, and system longevity.

Wind technology has rapidly evolved, and today’s components are engineered to withstand extreme environmental conditions, resist mechanical stress, and deliver precise control. A modern wind power system is far more than its iconic turbine blades; it is an integrated assembly of electrical, mechanical, and control elements working together to convert natural wind into usable, stable energy. This page provides an in-depth overview of the most critical components involved in that process and highlights why selecting top-tier parts is essential for long-term ROI and operational reliability.

Understanding Key Wind Energy Components

A well-functioning wind energy system depends on the coordination of multiple specialized parts. Each component serves a unique purpose and influences the system’s overall efficiency. Below is a detailed look at the major categories of Wind Energy Components that keep power systems running smoothly.

Turbine Blades and Rotor Assemblies

Turbine blades are the first point of interaction with wind. Modern blades are engineered using composite materials for maximum aerodynamic efficiency and durability. Along with the rotor hub, they determine how much kinetic energy can be captured. High-quality blades reduce turbulence, minimize noise, and ensure stable rotation even under fluctuating wind conditions. Their shape, length, and material composition significantly influence power output.

Nacelles, Gearboxes, and Drive Trains

Inside the nacelle lies the mechanical heart of the system. This housing typically contains the gearbox, drive shaft, main bearing, and generator. The gearbox plays a major role by converting the slow rotation of the blades into the high-speed motion required by the generator. Durable bearings, precision-aligned shafts, and optimized gearing ensure smooth, low-friction operation. These components are engineered to handle extreme mechanical loads and maintain efficiency over thousands of operational hours.

Generators and Electrical Conversion Equipment

The generator turns mechanical energy into electrical energy. Whether the system uses synchronous, asynchronous, or permanent-magnet generators, reliability and thermal stability are critical. Modern designs integrate advanced cooling systems, high-grade insulation, and smart controllers to ensure consistent output. Downstream from the generator, components like inverters, rectifiers, power converters, and grid-tie equipment help regulate electricity, stabilize voltage, and ensure compliance with grid standards.

Control Systems and Monitoring Devices

Wind turbines rely heavily on automated control systems for safe and efficient operation. These systems include sensors, anemometers, controllers, wind direction monitors, and braking systems. They allow real-time adjustments to blade pitch, yaw direction, and rotational speed. Modern control systems also feed data into monitoring platforms, enabling remote diagnostics and predictive maintenance. These capabilities reduce downtime and prevent damage caused by extreme weather or mechanical faults.

Towers, Foundations, and Structural Supports

Structural stability is essential for any wind installation. Towers must support heavy turbines while resisting high winds, vibrations, and environmental stress. They are often built from steel, concrete, or hybrid materials. Foundation systems—such as reinforced concrete pads, deep piles, or offshore anchors—ensure long-term stability. Proper structural components reduce maintenance costs and extend the lifespan of the entire system.

Why High-Quality Wind Energy Components Matter

Every component in a wind system has a measurable impact on performance, energy output, and operational costs. Inferior or outdated parts may lead to mechanical failures, reduced efficiency, or costly downtime.

Choosing high-grade components offers clear advantages:

- Higher energy output due to optimal aerodynamics and electrical efficiency

- Better durability with materials built to withstand corrosion, harsh weather, and continuous motion

- Enhanced safety and reliability thanks to advanced monitoring and fault-prevention systems

- Longer system lifespan, maximizing return on investment

- Lower maintenance costs through improved engineering and predictive diagnostics

Investing in premium Wind Energy Components is one of the most effective ways to future-proof a wind energy project and maintain consistent performance year after year.

Applications of Modern Wind Energy Components

These components support a wide range of applications, including:

- Utility-scale onshore and offshore wind farms

- Microgrid and hybrid-energy systems

- Commercial and industrial renewable installations

- Research and testing facilities

- Remote or off-grid power solutions

Regardless of scale, each installation benefits from components optimized for efficiency, weather resistance, and long-term dependability.