How to Test Solar Panel Output for Installers, EPCs & Asset Managers

For solar installers, EPCs, and asset managers, confirming a solar panel's real-world output isn't just a task—it's a critical risk management step. The most reliable field method involves using a digital multimeter to measure two key values under direct sunlight: Open-Circuit Voltage (Voc) and Short-Circuit Current (Isc). This process is the only way to verify that a panel from brands like BYD or Sungrow is performing to its spec sheet, protecting project bankability, streamlining commissioning, and ensuring long-term asset performance. This guide provides the exact steps, diagnostic frameworks, and pro tips needed to perform these tests accurately and safely on any job site.

Why Accurate Solar Panel Testing Matters for Your Bottom Line

Before you touch a single tool, it's crucial to understand the commercial stakes. Proper output testing is the firewall between a profitable, high-performing solar project and a future filled with expensive truck rolls, warranty claims, and liquidated damages.

Verifying a panel's performance on-site is a fundamental quality assurance step that directly protects your reputation and profitability.

Here’s why this matters for your specific role:

- For Installers: Catching a single underperforming panel before it's wired into a string saves hours of troubleshooting and avoids costly callbacks. It validates that the Qcells or Canadian Solar modules you just unboxed perform as advertised.

- For EPCs & Developers: Proven on-site performance data is non-negotiable for project bankability and meeting performance guarantees. Accurate testing streamlines the commissioning process and provides the hard data needed to satisfy investors and asset owners.

- For Asset Managers & O&M Techs: When troubleshooting system underperformance, testing individual panels is the fastest way to isolate the root cause, whether it's degradation, a faulty bypass diode, or physical damage.

The Core Metrics You Must Master

At the heart of every field test are two critical electrical measurements, taken with a multimeter under real-world sun conditions. Safety is paramount—always wear Class 0 insulated gloves and follow proper Lockout/Tagout (LOTO) procedures to mitigate electrical hazards.

This hands-on approach immediately confirms if a panel is living up to its rated power under Standard Test Conditions (STC). For a deeper dive into these procedures, the team at Elite Home Energy Solutions has some great insights.

Pro Tip: For any field technician, mastering Voc and Isc is non-negotiable. They are the vital signs of a solar panel. An anomalous reading in either metric points directly to a specific problem, eliminating guesswork during troubleshooting.

You’ll be focusing on two values printed right on every panel's nameplate sticker: Open-Circuit Voltage (Voc) and Short-Circuit Current (Isc).

Quick-Reference Diagnostic Table: Voc vs. Isc

| Metric (Abbreviation) | What It Measures | Why It Matters for Pros |

|---|---|---|

| Open-Circuit Voltage (Voc) | The maximum voltage a panel produces with no load connected (its electrical potential). | A significantly low Voc reading (adjusted for temperature) often points to damaged cells, faulty bypass diodes, or internal wiring faults. It's a key indicator of panel integrity. |

| Short-Circuit Current (Isc) | The maximum current (amps) a panel produces when its positive and negative terminals are shorted. It’s a direct measure of electron flow. | Isc is directly proportional to solar irradiance. A low Isc reading on a sunny day is a red flag for soiling, shading, or significant cell degradation. |

Understanding these values is crucial. A low Voc suggests a potential internal, physical problem with the panel itself. It's a measure of the panel's health.

On the other hand, a low Isc reading on a bright, sunny day often points to external factors like a dirty surface, partial shading, or long-term degradation. It’s a direct indicator of how well the panel is converting available sunlight into a flow of electricity.

Assembling Your Field Testing Toolkit

Arriving on-site unprepared is the fastest way to waste time and collect unreliable data. For any solar professional, having the right field testing toolkit is non-negotiable for performing tests safely, efficiently, and accurately.

The goal isn't just to own the tools; it's to understand their specific role in diagnosing system health. It's not about the most expensive gear but the right gear for the task. Furthermore, embracing the importance of using checklists ensures your preparation is methodical, preventing simple but costly field errors.

Core Diagnostic Instruments

These tools provide the raw data needed to determine a panel's health. Knowing which instrument to use for a specific scenario is what defines a true professional.

- Digital Multimeter (DMM): The workhorse of your toolkit. A quality, CAT III or CAT IV rated DMM is essential for safely measuring Voc and Isc. It’s your primary tool for rapid validation during commissioning and troubleshooting.

- DC Clamp Meter: For measuring current without de-energizing or cutting into circuits, a DC clamp meter is indispensable. It provides a safe and fast way to check amperage at the conductor, string, or combiner box level.

- Solar Irradiance Meter (Pyranometer): Your multimeter provides the electrical data, but a pyranometer provides the critical environmental context. It measures the intensity of sunlight (in W/m²) hitting the panel's surface. Without this data, you cannot accurately determine if low current is due to a faulty panel or simply low light conditions.

Tooling Recommendations by Segment

The tools in your bag should be tailored to the job's scale and complexity.

For Residential & Commercial Installers: A rugged, reliable DMM is your daily driver for 90% of diagnostic work. Paired with a DC clamp meter and a basic infrared (IR) thermometer to gauge panel temperature, this setup allows you to diagnose most common issues and verify system performance before leaving the site.

For EPCs & Commissioning Agents: On large-scale projects, an I-V Curve Tracer becomes a mission-critical asset. While a DMM is still essential, an I-V curve tracer provides a complete performance snapshot of a panel or entire string, delivering the bankable, high-fidelity data required for performance guarantees, financial models, and comprehensive QA/QC reporting.

Non-Negotiable Safety Gear

No diagnostic test is worth a safety incident. Electrical hazards in a solar array are significant, and Personal Protective Equipment (PPE) is your first and most critical line of defense.

Your kit must always include:

- Insulated Gloves: Class 0 gloves rated for 1,000V are the U.S. industry standard. Never work on energized DC solar circuits without them.

- Safety Glasses: An arc flash or flying debris can cause life-altering injury.

- Lockout/Tagout (LOTO) Kit: Essential for ensuring circuits are de-energized and remain so while you work, in compliance with OSHA standards.

Prioritizing these tools and safety protocols is fundamental to all professional solar energy solutions.

Step-by-Step Guide: Testing Solar Panel Output with a Multimeter

This is where theory meets the real world. For any field technician, a quality digital multimeter is the fastest tool for a definitive health check on a solar panel. The process is straightforward, but precision and safety are what separate professional work from amateur mistakes.

We're gathering hard data to verify if a panel from a top-tier brand like Fronius or FranklinWH is delivering what its spec sheet promises under current site conditions. This on-the-spot validation is critical during commissioning and essential for isolating faults in an underperforming string.

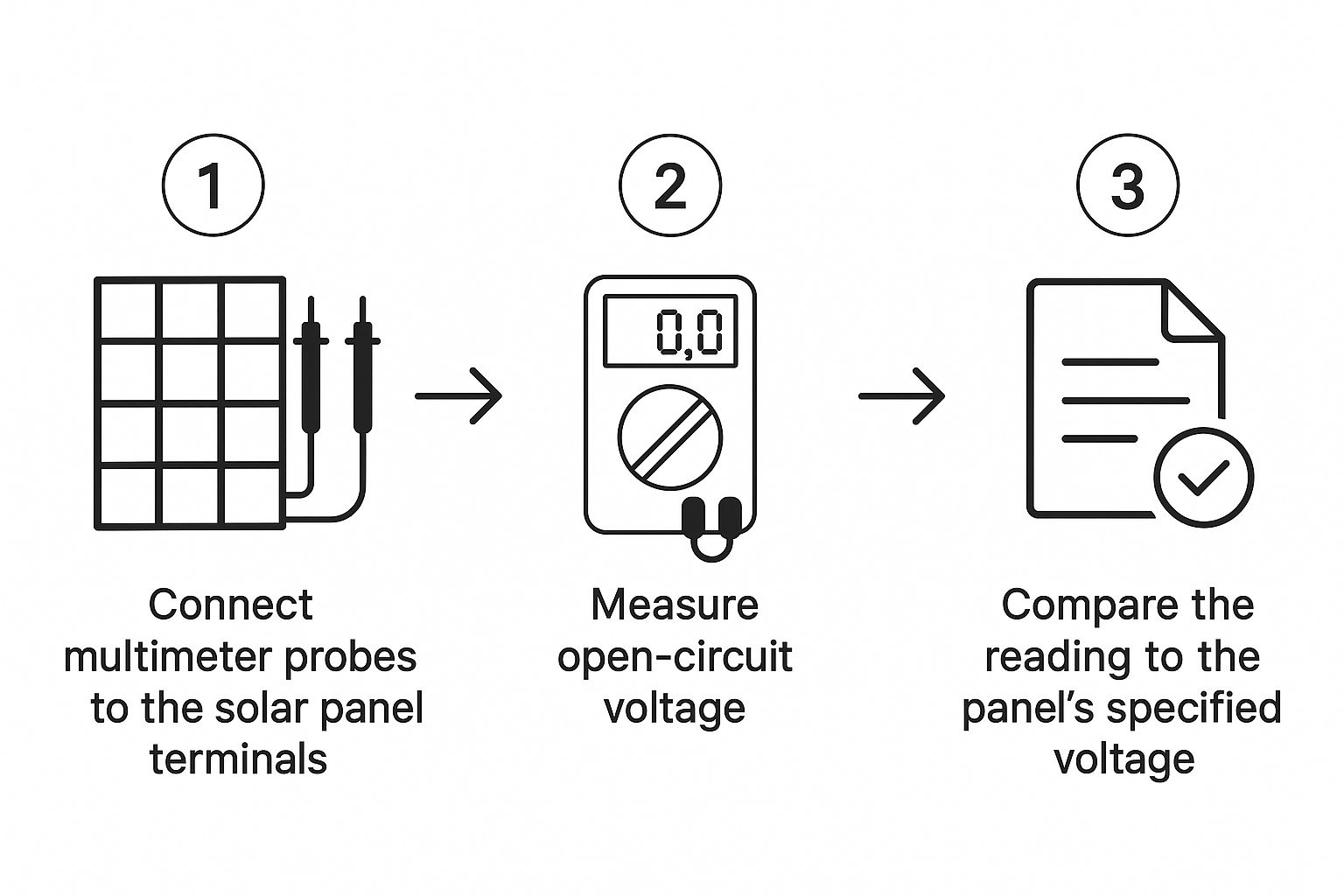

Step 1: Measuring Open-Circuit Voltage (Voc)

Voc is the maximum voltage a panel can produce when it is not connected to a load. Think of it as the raw electrical "pressure" in the system.

Set your multimeter to the DC voltage (VDC) setting, ensuring the range is higher than the panel’s rated Voc found on its nameplate. With the panel safely disconnected from the system and under direct, unobstructed sunlight, carefully connect the red probe to the positive MC4 terminal and the black probe to the negative terminal. The stable reading on your meter is the Voc.

Pro Tip: The best time to take readings is near solar noon when the sun is at its highest point. This provides the most intense and stable solar irradiance, giving you the most reliable data for comparison against the panel's STC ratings.

Step 2: Measuring Short-Circuit Current (Isc)

Isc is the maximum amperage a panel can produce. This value is highly sensitive to the intensity of the sunlight.

Switch your multimeter dial to a high DC amps setting (typically the 10A or 20A setting). Crucially, you must also move the red probe to the dedicated amps port on the meter. Forgetting this step is a common error and can blow the fuse in your meter.

With the panel in full sun, briefly connect the probes to the positive and negative terminals to create a momentary short circuit. The reading you see is the Isc.

CRITICAL SAFETY NOTE: Do not maintain this connection for more than a couple of seconds. A prolonged short circuit can stress and potentially damage the solar cells.

Practical Field Considerations & Common Mistakes

- Use an MC4 Disconnect Tool: Never use a screwdriver or pliers to separate MC4 connectors. This damages the locking tabs and compromises the weather-tight seal, leading to moisture intrusion and future failure.

- Ensure a Solid Connection: Make sure your multimeter probes make firm, deep contact within the MC4 connectors. A loose connection will result in fluctuating, useless readings.

- Double-Check Meter Settings: Before each test, confirm your multimeter is set to the correct function (VDC for Voc, ADC for Isc) and that the probes are in the correct ports.

Mastering these quick tests allows a technician to confidently commission a system or surgically pinpoint a faulty panel, saving valuable time and ensuring project integrity.

How to Interpret Your Test Results: A Diagnostic Framework

Collecting data is only half the battle. The true skill lies in correctly interpreting what those numbers mean in the context of the job site. Your voltage and current readings are useless without comparing them to the panel's nameplate ratings and adjusting for real-world conditions.

Nameplate specs are determined under Standard Test Conditions (STC): a lab environment with 1000 W/m² irradiance, a 25°C (77°F) cell temperature, and a specific light spectrum (AM1.5). This creates a perfect-world performance baseline. You can get a deeper dive into how these lab conditions are set on ecoflow.com.

A real-world rooftop is not a lab. You must account for site variables to make an accurate diagnosis.

Adjusting for Real-World Conditions

Your field readings will almost never perfectly match the nameplate values. This is normal. The key is to determine if the variance is expected or indicates a problem.

Two primary variables will impact your readings:

- Temperature: As a solar panel gets hotter, its voltage (Voc) decreases. On a hot, sunny day, it's common for Voc readings to be 10-20% lower than the STC rating. Conversely, on a very cold but bright day, the Voc can be higher than the nameplate value. This is a critical factor for string sizing per NEC guidelines.

- Irradiance: Sunlight intensity directly impacts current (Isc). Haze, passing clouds, or low sun angle will reduce irradiance, causing a proportional drop in Isc. Soiling from dust, pollen, or pollution has the same effect.

Different panel technologies also behave differently. To understand these nuances, review our guide to the best solar panel brands to see how various designs and manufacturers compare.

A Simple Diagnostic Framework

Use this mental checklist to quickly assess panel health on-site.

If Voc is significantly low...

After accounting for high temperatures, a voltage reading that is drastically off spec (e.g., 50% or lower) is a major red flag. This typically indicates a serious internal failure, such as multiple damaged cells or a failed bypass diode.

If Isc is unexpectedly low...

First, rule out external factors. Low current on a clear day is often caused by soiling or partial shading. Before condemning the panel, check for shadows from vents or trees and ensure the panel surface is clean.

By using the nameplate as your baseline and intelligently adjusting for site conditions, you can move from just collecting data to making confident, cost-saving decisions on every project.

Troubleshooting Common Panel Output Issues

When your multimeter readings don't align with expectations, it's time to shift from testing to troubleshooting. Before assuming a panel is defective, remember that low output is most often caused by environmental factors or simple connection issues that can be resolved on-site.

A methodical diagnostic process is crucial. You don’t want to initiate a warranty claim with a manufacturer like Cummins or Qcells only to discover the root cause was a dirty panel. This disciplined approach saves time, money, and protects your credibility.

Physical Inspection and Obvious Faults

Your eyes are your most effective initial tool. A thorough visual inspection can often identify the problem immediately.

- Look for Damage: Scan for cracks, chips, hotspots (discoloration), or delamination. Any physical damage can compromise internal circuits and cause a significant voltage drop.

- Check for Soiling: A thick layer of dirt, pollen, or bird droppings acts as a film, blocking sunlight and reducing current (Isc). Proper solar panel cleaning techniques are essential for maintaining peak performance.

- Identify Shading: Even small shadows from a vent pipe, antenna, or tree branch can trigger bypass diodes and cause a disproportionately large drop in output.

Investigating Electrical Connections

If a physical inspection reveals no issues, investigate the wiring. A surprising number of output problems stem from faulty connections.

Critical Mistake: Never write off a panel before checking its connections. A corroded or improperly seated MC4 connector is a common and easily fixable point of failure. Use an MC4 tool to disconnect the leads and inspect the pins for moisture intrusion or discoloration, which are clear signs of a poor connection. A bad connection acts as a point of high resistance, choking the flow of electricity and killing output.

Temperature and Irradiance Factors

Always contextualize your readings with environmental data. Panel efficiency is directly impacted by heat and light. A 2023 study confirmed that for every 1°C increase in cell temperature, mono-Si PERC cell efficiency drops by about 0.0316 percentage points.

This is vital for interpreting your results. A lower-than-expected voltage on a hot afternoon is normal. A cold, bright winter day can push voltage higher than the STC rating. Understanding seasonal effects is key to an accurate diagnosis, a topic covered in our guide to solar panel output in summer vs. winter.

On-Site Diagnostic Table for Technicians

Use this table to quickly pinpoint common issues based on your test results.

| Symptom (Test Result) | Potential Cause | Recommended Action |

|---|---|---|

| Low Voc, Normal Isc | Partial shading on cells; internal cell damage | Identify and eliminate shading source. If no shading, inspect for microcracks or hotspots with a thermal camera. |

| Normal Voc, Low Isc | Heavy soiling (dirt, dust, pollen); panel degradation | Clean the panel surface thoroughly. Compare to a clean reference panel under identical conditions. |

| Voc and Isc both low | Widespread shading; high cell temperature; low solar irradiance | Re-test during optimal sun conditions (midday, clear sky). Measure panel temperature and irradiance to verify conditions. |

| Voc = 0, Isc = 0 | Open circuit; faulty MC4 connector; severed internal wire; blown bypass diode | Check all connections with an MC4 tool. Inspect the junction box. Test bypass diodes if accessible. |

| Normal Voc, Isc = 0 | Open circuit in test setup; faulty meter; internal panel fault | Verify multimeter function and probe connections. Re-test. If the issue persists, the panel has an internal open circuit. |

This framework is your starting point. Always follow a process of elimination, starting with the simplest and most common explanations first.

Questions From the Field

Here are answers to common questions that arise during on-site solar panel testing.

Can I Test a Solar Panel on a Cloudy Day?

Yes, but with significant limitations. A panel will still produce a measurable voltage (Voc) on an overcast day, often surprisingly close to its nameplate rating. This makes it useful for a quick continuity or "go/no-go" check.

However, the current (Isc) will be drastically lower because it is directly proportional to solar irradiance. Therefore, a cloudy-day test cannot be used to validate a panel's peak performance. For that, you need clear, sunny skies.

How Often Should Panel Output Be Tested?

Routine output testing is not required for a healthy, operational system. Testing is situational and event-driven.

- At Commissioning: This is mandatory. Testing upon installation is the only way to verify that all panels are performing to spec from day one, which is a critical step in project handover and quality assurance.

- For Troubleshooting: If monitoring software indicates a sudden drop in system production, it's time to test. Field testing individual panels or strings is the most efficient method for isolating an underperforming or failed module.

Otherwise, routine visual inspections for soiling, damage, or new shading sources are sufficient.

What Does It Mean If I Have Voltage But No Current?

This is a classic diagnostic scenario. If you measure a healthy Voc but get a zero (or near-zero) reading for Isc, it almost always indicates an open circuit.

The solar cells are generating a voltage potential, but there is a break somewhere preventing the current from flowing. The fault could be a loose MC4 connector, a broken wire in the junction box, a failed solder joint, or an internal fault within the panel laminate. Your voltage reading confirms the panel is "live," but the lack of current means the electrical path is incomplete.

When testing identifies a need for replacement, Portlandia Electric Supply provides the in-stock inventory and logistics to keep your project on schedule. Our NABCEP-certified team can support your design and procurement needs. Request a Bulk Quote and get the right equipment delivered to your job site, fast.