Kilowatt Hours to Amps: A Practical Guide for Sizing and Safety

Here's the problem electrical installers, EPCs, and project managers face daily: you can't directly convert kilowatt-hours (kWh) to amps. This isn't just a technicality; getting the relationship wrong can lead to project delays, failed inspections, and critical safety hazards.

This guide provides a direct, no-nonsense framework for anyone specifying, installing, or managing electrical systems. It moves beyond theory to show how to accurately calculate amperage from energy consumption data, ensuring your projects are safe, compliant, and correctly sized from the start. We will cover the core formula, real-world project examples for installers and facility managers, and critical compliance watchouts required by U.S. electrical codes.

Why Converting kWh to Amps Is Critical for Your Project

Getting a handle on how to translate kilowatt-hours to amps isn't a textbook exercise. For installers, EPCs, and even clued-in homeowners, it’s a foundational skill for ensuring project safety, reliable system performance, and NEC compliance. This single calculation is the bedrock of any sound electrical design, directly impacting project timelines, budgets, and operational success.

Real-World Project Impact

Getting this conversion right is everything on the job site. It’s the difference between a safe, efficient system and a hazardous one. It directly impacts:

- Sizing Circuit Breakers: Ensures breakers can handle the real-world load without nuisance tripping, while guaranteeing they trip during a genuine overcurrent event as required by the NEC.

- Selecting Wire Gauge: Your amperage calculation dictates the required wire thickness (AWG). Undersizing wires is a primary cause of overheating and presents a major fire hazard.

- Assessing Panel Capacity: Determines if a facility or home’s main panel can support new high-draw loads like EV chargers, heat pumps, or commercial machinery without dangerous overloads.

A mistake here isn't a small oversight. It can lead to fried equipment, overloaded circuits, and serious safety risks. The formula that connects these concepts is:

Amps = (kWh × 1000) / (Voltage × Hours)

For a standard 120V U.S. residential circuit, a device consuming 1 kWh of energy over a single hour draws a current of 8.33 amps.

Expert Tip: Think of kWh as the total fuel in a tank and amps as how fast that fuel is flowing at a specific moment. You must design systems for the peak flow (maximum amperage), not just the average, to build a system that won't fail under pressure. This is a core principle of NEC load calculation.

To give you a clearer picture, here’s a quick reference for how 1 kWh of usage over one hour translates to amps at different common voltages.

Quick Conversion Reference: Amps from 1 kWh Usage in One Hour

This table shows the amperage draw from consuming 1 kWh over one hour. Notice how as the voltage increases, the required amperage to deliver the same power decreases—a fundamental concept for efficient electrical system design and a key reason high-voltage systems are used in industrial applications.

| System Voltage | Amps (from 1 kWh in 1 hour) | Common U.S. Application |

|---|---|---|

| 120V | 8.33 A | Standard U.S. residential outlets, lighting |

| 208V | 4.81 A | Three-phase commercial systems (light) |

| 240V | 4.17 A | U.S. residential (dryers, EV chargers), split-phase |

| 277V | 3.61 A | Commercial lighting systems |

| 480V | 2.08 A | Industrial machinery, large commercial HVAC |

This guide is designed to move you from theory to practice, giving you the real-world knowledge needed to execute safe and efficient electrical work. For more hands-on advice and project guides, be sure to check out our other articles and technical posts.

The Core Formula for Accurate Amp Calculations

When you're in the field or designing a system, you must get from kilowatt-hours to amps quickly and accurately. There’s a go-to formula that connects energy usage (kWh) to the actual electrical current (amps) flowing through your wires. Mastering this is fundamental to any successful project.

Here's the formula you need to know:

Amps = (kWh × 1,000) / (Voltage × Hours)

Let's break down each variable. It’s easy to make a mistake if you grab the wrong number, so a quick review is always a good idea before you start punching numbers into a calculator.

Understanding the Variables

- Kilowatt-Hours (kWh): Your starting point—the total energy consumed over a period. You’ll pull this from a utility bill, an appliance's EnergyGuide label, or the spec sheet for equipment like a BYD battery system or a Cummins generator.

- Voltage (V): The electrical potential of the circuit. It's absolutely critical to use the correct value for your specific application. This could be 120V for a standard home outlet, 240V for a larger load like an EV charger, or even 48V for an off-grid solar setup.

- Hours: This variable is where many errors occur. The number of hours must directly correspond to the timeframe over which the kWh figure was measured. If kWh is from a 24-hour period, Hours must be 24. A mismatch here will render your calculation useless.

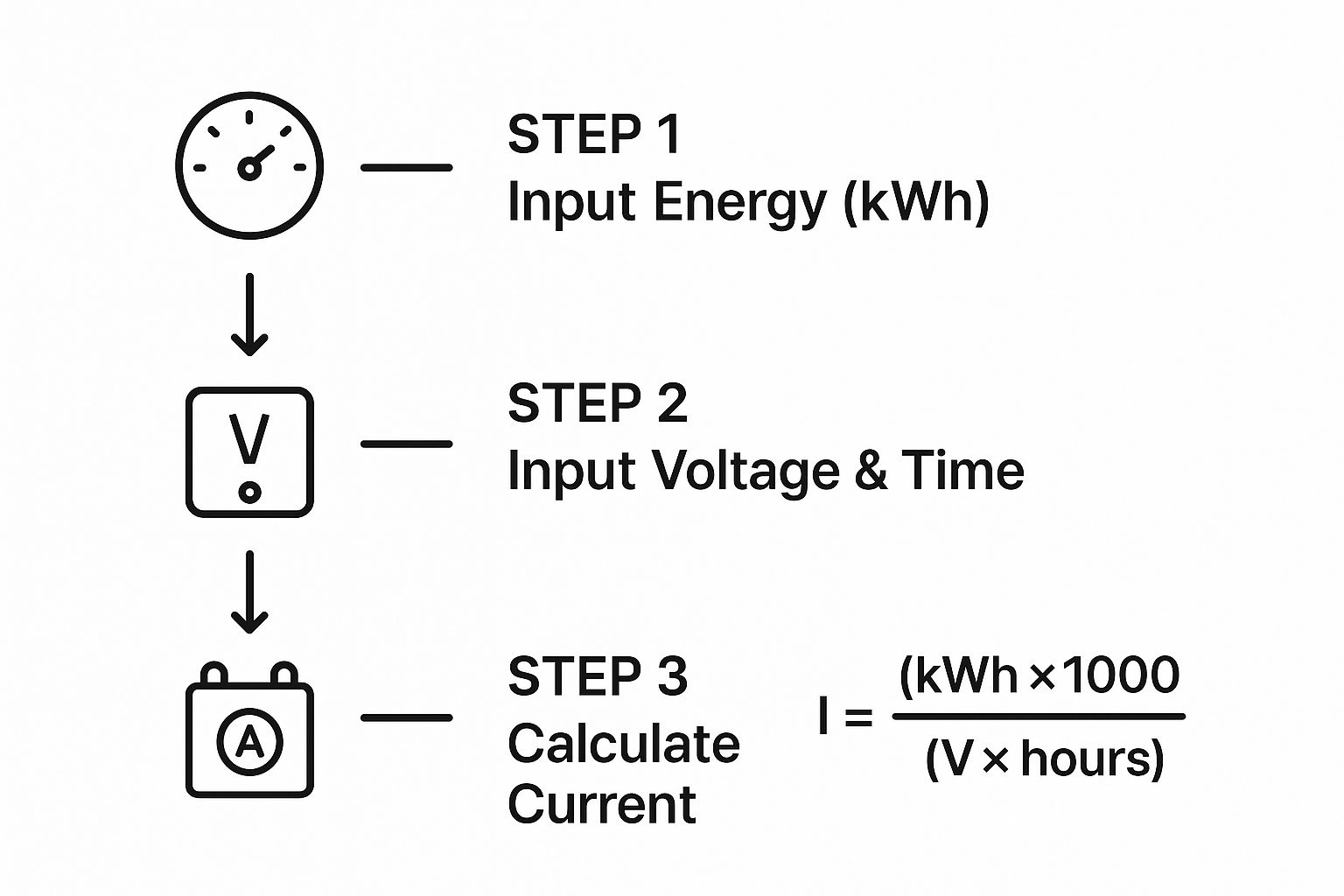

This infographic gives you a clean visual of how these inputs come together.

As you can see, it's a logical flow: start with the total energy consumed, plug in the system's voltage and the time it was used, and you get the current.

A Practical Field Example: Sizing for Energy Storage

Knowing the formula is one thing; using it correctly on a job site is what really counts. Let’s run through a common scenario for an energy storage installation.

Scenario: An installer is commissioning a FranklinWH aPower energy storage unit. The homeowner wants the battery to discharge 5 kWh of stored energy to run their essential appliances during a 4-hour evening peak-rate period. The system is tied into a standard 240V circuit.

Using our formula, we can determine the continuous amp draw:

- Amps = (5 kWh × 1,000) / (240V × 4 hours)

- Amps = 5,000 / 960

- Amps = 5.21 A

This quick calculation tells the installer that the FranklinWH unit will draw a steady 5.21 amps for that entire 4-hour window. This is critical information. It confirms that the existing circuit breaker and wiring are properly sized for the job, ensuring the installation is not just functional, but safe and fully compliant with NEC standards.

Putting the Conversion to Work in the Real World

Knowing the theory is one thing, but applying the kWh-to-amps conversion is where projects succeed or fail. This calculation isn't just a number—it informs equipment choices, dictates safety measures, and ensures compliance with standards like the NEC. Let's ground this in scenarios you will face in the field.

For the Solar Installer Sizing a System

A solar contractor is on-site to install a new Sungrow inverter with a battery bank. The customer's main goal is to power their home through the evening peak, which uses an average of 6 kWh over a 4-hour window. The system is designed to run on a standard 240V circuit. Before pulling a single wire, the installer must know the continuous amp draw to correctly size the wiring and overcurrent protection.

- The Math: Amps = (6 kWh × 1,000) / (240V × 4 hours) = 6.25 A

- The Action: The 6.25A figure confirms that standard 14 AWG wire on a 15A breaker is sufficient for the continuous load. This guarantees a safe, NEC-compliant installation that won't fail due to undersized components. This isn't an optional step; it's a critical part of the design and permitting process.

For the Facility Manager Evaluating New Loads

A facility manager is planning to add a new piece of manufacturing equipment. The spec sheet states it will pull 120 kWh over an 8-hour shift, and the facility runs on a 480V 3-phase system. The critical question is whether the existing subpanel can handle it. The formula needs a slight tweak for 3-phase power.

- The Math: Amps = (120 kWh × 1,000) / (480V × 8 hours × 1.732) = 18.04 A

- The Action: This calculation shows the new machine adds a continuous load of just over 18 amps. The manager can now check the panel schedule and breakers to confirm available capacity before the equipment arrives, avoiding costly delays and electrical upgrades.

For the Homeowner Planning an Upgrade

A homeowner wants to install a new high-efficiency heat pump on an existing 20A, 240V circuit. The unit's documentation states it consumes 2.4 kWh during a typical 3-hour winter heating cycle.

- The Math: Amps = (2.4 kWh × 1,000) / (240V × 3 hours) = 3.33 A

- The Action: The 3.33A continuous draw is well under the 20A limit. However, an experienced electrician knows to account for the startup (inrush) current, which is much higher for a motor. The pro must verify the breaker is an HACR-type, rated specifically for motor startup, to prevent nuisance tripping.

Ultimately, understanding the kWh to Amps conversion is fundamental for anyone working with electrical systems. It's key when implementing solutions like energy rate reduction services or simply planning for future electrical needs. For reference, the average American home uses about 29 kWh per day. On a 120V system, that works out to a continuous draw around 10.1 amps—a critical baseline for both utilities and homeowners.

Common Mistakes and Compliance Watchouts

Accurate electrical calculations are the bedrock of any safe project. Even experienced pros can stumble over common traps when converting kWh to amps. These aren't just math mistakes; they lead to dangerous installations, failed inspections, and rework that blows project budgets and timelines.

Compliance Watchout: The NEC Requires It

Let's be clear: proper load calculations aren't just a good idea—they're mandated by the National Electrical Code (NEC). Getting this wrong means you'll fail inspection, forcing expensive and time-consuming fixes. Always design for compliance from the start.

Critical Mistake #1: Using the Wrong Voltage

One of the most frequent errors is plugging the wrong system voltage into the formula. Using 120V for your math when dealing with a 240V appliance (like a heat pump or EV charger) is a massive oversight. This single mistake will dangerously underestimate the current and lead to undersized wiring and breakers.

Critical Mistake #2: Confusing Average vs. Peak Amps

Your calculation might show a nice, steady average draw that seems manageable. But the moment a motor or compressor kicks on, the startup (inrush) current can spike dramatically. Sizing breakers based only on average load is a recipe for nuisance trips and can damage equipment over time. You must account for both continuous load and potential peak demand.

Critical Mistake #3: Misapplying the Time Variable

Here’s a subtle but critical error: mismatching the time variable. It's easy to default to "1 hour" in your calculation. But what if the kWh figure you're using, say 24 kWh, represents a full day's energy consumption? If you calculate its draw over just one hour, you'll end up with a wildly inflated and incorrect amperage. Your "hours" input must match the time period of your kWh measurement.

Historically, the standardization of these electrical units was fundamental to building a safe, functional grid. The U.S. adoption of 120V residential service directly shaped how we approach current loads. Understanding that pulling 8.33 amps for one hour equates to 1 kWh of use helped define ratings for our ubiquitous 15A and 20A home circuits. For more background, you can find great info on how these units shaped the electrical industry on litime.com.

From Calculation to Confident Project Execution

You’ve crunched the numbers and walked through the real-world examples. Now comes the most important part: turning those kWh-to-amps calculations into a safe, successful project. Getting this conversion right isn't just about passing an inspection—it's the bedrock of any electrical system that's safe, efficient, and up to NEC standards.

For Installers & EPCs

With your load calculations locked in, you have the exact data you need to build out a complete bill of materials. Let Portlandia Electric Supply help with the next step. We provide real in-stock inventory of correctly sized breakers, wiring, and components from top-tier brands like BYD, Sungrow, and Cummins, with bundled logistics to get it to your job site fast.

Pro Tip: Don't let a small miscalculation derail your project. A quick double-check on your voltage and time variables before placing an equipment order can save you thousands in rework costs and delays.

For Homeowners

Feeling out of your depth trying to figure out if your home's electrical panel can handle a new EV charger or solar battery? Guessing is not an option. Use our PowerLink service to connect with a qualified local installer. They'll perform a professional site assessment, giving you absolute confidence that your home is ready for the upgrade. For more insights on system design, visit our energy solutions blog.

Common Questions About kWh to Amp Conversions

Even with the formula down, real-world electrical work always presents new questions. Let's tackle the most common ones so you can handle any scenario with confidence.

Can I Convert kWh to Amps Without Knowing the Voltage?

No, this is impossible. You absolutely must know the system's voltage to get an accurate amp reading. Amperage is a direct result of both the total energy used (kWh) and the electrical "pressure" (voltage). Think of water flowing through a hose: you can move the same volume of water (energy) through a small opening if the pressure is high (high voltage, low amps), or through a much larger opening if the pressure is low (low voltage, high amps). Without knowing the pressure, you can’t determine the flow rate. Always confirm if you're dealing with a 120V, 240V, or another voltage standard before starting calculations.

How Do I Handle 3-Phase Power in My Calculation?

This is a critical distinction for commercial or industrial settings. For these systems, you must introduce the square root of 3 to account for the phase difference.

The 3-Phase Formula: Amps = (kWh × 1,000) / (Voltage × Hours × 1.732)

That "magic number," 1.732, is the phase factor that accounts for how power is balanced across the circuit's three legs. Forgetting to include it is one of the most common—and dangerous—mistakes when sizing equipment for a 3-phase application.

Does This Formula Work for Both AC and DC Systems?

Yes, absolutely. The fundamental physics connecting energy (kWh), voltage, and current (amps) are the same for both Alternating Current (AC) and Direct Current (DC). Whether you're sizing a standard residential AC circuit, a 48V DC battery bank for an off-grid solar system, or a heavy-duty commercial EV charger, the formula works. The only thing that changes is the specific voltage value you plug in for the system you're analyzing.

At Portlandia Electric Supply, we go beyond formulas. We provide the in-stock components, bundled logistics, and expert support you need to see your project through to completion. Request a Quote today and let our team build a complete bill of materials perfectly tailored to your load requirements.