Your Guide to Solar Panel System Components: An Installer's Field Manual

A complete solar installation is more than just the panels on the roof—it's an integrated collection of solar panel system components including panels, inverters, racking, and balance-of-system hardware. For solar installers, EPCs, and developers, mastering how these components function and interact is critical to designing and building high-performance, code-compliant, and profitable solar projects. This guide breaks down each component, providing the real-world context needed to optimize procurement, streamline installation, and guarantee long-term system bankability.

Decoding Your Complete Solar PV System

This guide provides actionable insights for professionals who design, source, and build these projects daily. Understanding how these parts function and fit together is the bedrock of designing a durable and code-compliant solar array. We'll move past the spec sheets to explore the practical implications of every choice you make, from module selection to the nuts and bolts of your bill of materials (BOM).

Who This Guide Is For

This guide is built for the professionals on the front lines of the solar industry. Each section includes specific takeaways for different roles in the project lifecycle.

- For Installers & Contractors: Get clarity on component selection to reduce time on-site, ensure compatibility, and avoid costly project delays. We'll highlight ways to streamline your workflow and pass inspections the first time.

- For EPCs & Developers: Make smarter procurement decisions by understanding how component choices impact system performance, project timelines, and logistics, from commercial rooftops to utility-scale fields.

- For Procurement Managers: Optimize your BOM by seeing how sourcing decisions—like bundled freight and kitted solutions from Portlandia Electric Supply—ripple through the entire project, affecting everything from logistics costs to long-term reliability.

- For Homeowners & Facility Managers: Build a solid understanding of your investment. This knowledge empowers you to have more productive conversations with contractors and truly grasp what your system is designed to do.

A solar energy system is a sophisticated assembly where the performance of the whole is dictated by the quality and compatibility of its individual parts. Selecting the right components is not just a technical choice—it's a critical business decision that impacts project timelines, budgets, and the long-term bankability of the asset.

The Real-World Impact of Component Knowledge

A detailed understanding of solar panel system components directly impacts your bottom line. Choosing an inverter that isn't matched to the site conditions can lead to massive energy production losses over the system's 25-year life. Similarly, glossing over racking hardware specs can lead to a failed inspection or, worse, a structural failure that doesn't comply with local wind load codes (ASCE 7-16).

This guide frames each component in the context of practical, on-the-ground decision-making. We'll explore not just what each part does, but why its selection is critical for performance, safety, and profitability. For a deeper dive into the primary power-generating component, see our detailed guide on choosing the right solar panels.

The Power Duo: Solar Panels and Inverters

Every solar PV system is built around two core components: the solar panels that capture sunlight and the inverters that convert it into usable power. For any installer, EPC, or developer, selecting the right combination of these solar panel system components is the single most important design decision, dictating performance, cost-per-watt, and long-term project bankability.

Solar panels (PV modules) convert sunlight into direct current (DC) electricity. The inverter is the brains of the operation, taking that raw DC power and converting it into alternating current (AC) electricity, the standard used by buildings and the utility grid. Without a compatible, high-quality inverter, the energy your panels produce is useless.

Advances in Solar Panel Technology

The solar module market is constantly evolving, with new technologies pushing efficiencies higher and improving performance in real-world conditions. Understanding these differences is key to specifying the right product.

- Monocrystalline Panels: Known for high efficiency and a sleek black appearance, these are the go-to for residential projects where space is a premium.

- Polycrystalline Panels: A budget-friendlier option with slightly lower efficiency, identifiable by their blue, marbled look.

- TOPCon and Bifacial Innovations: The latest technologies are pushing performance further. Tunnel Oxide Passivated Contact (TOPCon) cells reduce energy loss and boost efficiency. Bifacial modules capture sunlight from both sides, a game-changer for ground-mounts and flat commercial roofs with reflective surfaces.

These advancements directly impact project financials. Higher efficiency modules can reduce the number of panels needed, lowering balance-of-system (BOS) and labor costs. According to recent market data, commercial PV system prices have dropped, with advanced modules being a significant driver of this trend.

Choosing the Right Inverter Technology

Your choice between string inverters, microinverters, or power optimizers has major implications for system design, monitoring, and maintenance.

The inverter determines how your solar array handles shade, manages individual panel output, and reports performance data. This decision is fundamental to the system's intelligence and resilience.

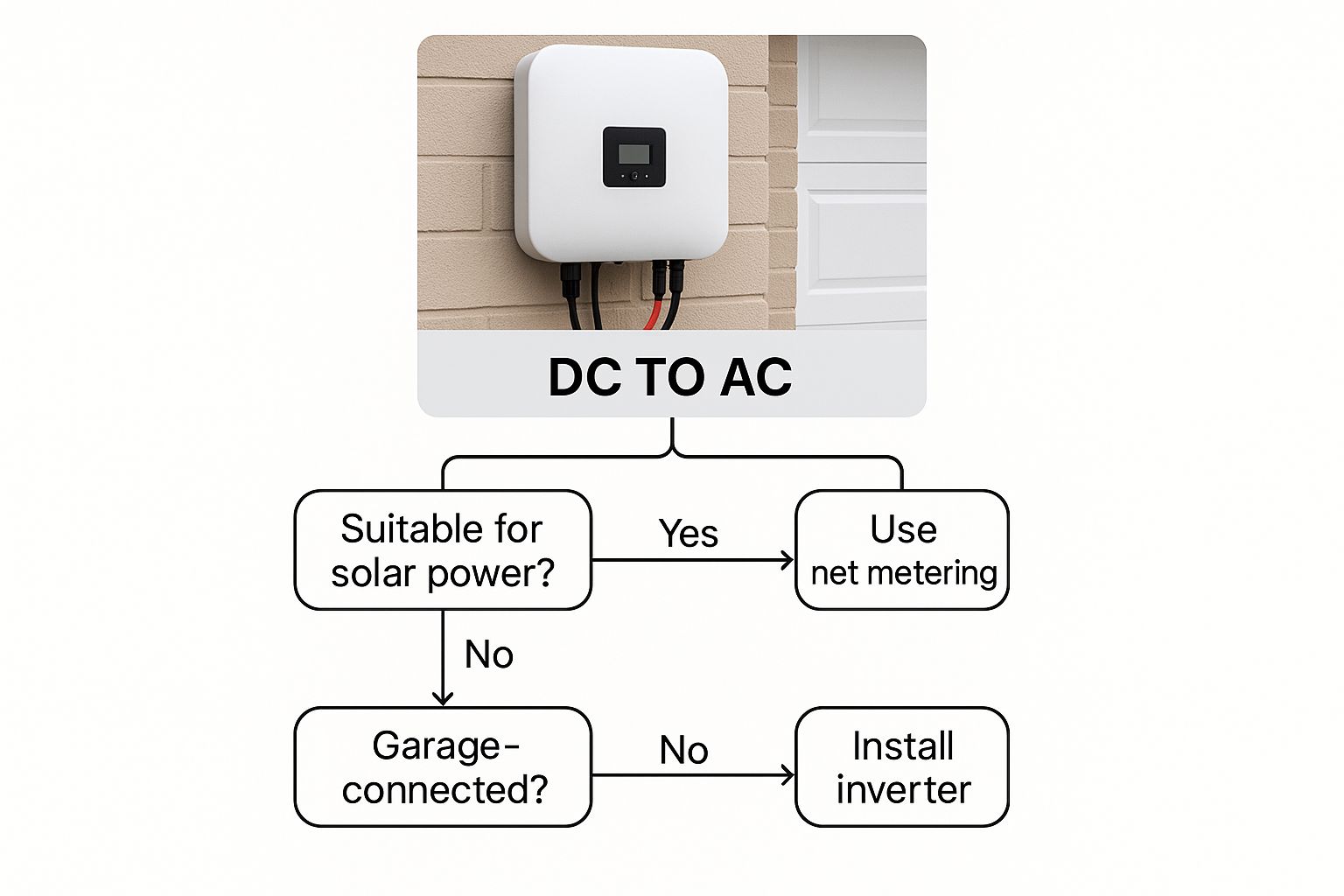

This image breaks down the inverter's core function: turning DC from the panels into the AC your property actually uses.

This DC-to-AC conversion is the essential step that makes solar energy compatible with the grid and all connected appliances. For a more detailed breakdown, check out our in-depth guide to choosing the right solar inverter.

Inverter Technology Comparison for Solar Professionals

Selecting the right inverter involves balancing performance requirements, site specifics, and budget. This table offers a quick comparison for different project scales.

| Inverter Type | Best For | Key Advantage | Primary Consideration |

|---|---|---|---|

| String Inverters | Large, unshaded commercial roofs or ground mounts with uniform orientation. Brands like Sungrow and Fronius are leaders in this space. | Lower upfront cost per watt and simplified maintenance on a single unit. | A single shaded or underperforming panel can reduce output for the entire string. |

| Microinverters | Residential or complex commercial roofs with multiple angles, orientations, or shading issues. | Panel-level optimization maximizes energy harvest; no single point of system failure. Panel-level monitoring is standard. | Higher initial equipment cost and more components to install on the roof. |

| Power Optimizers | Systems needing panel-level optimization but with the cost structure of a string inverter. | Combines panel-level MPPT for shade tolerance with a centralized, cost-effective inverter. | More complex wiring than a standard string system; still relies on a central inverter for DC-AC conversion. |

The right choice balances upfront cost against long-term energy yield and monitoring needs to deliver the best ROI for your client.

Mounting and Racking: The Unsung Heroes of Solar

While panels and inverters get the attention, the mounting and racking hardware is the engineered structure designed to secure a high-value asset to a building or the ground for 25 years or more. For procurement managers and project developers, selecting the right racking is a critical decision that directly impacts installation labor, system safety, and long-term bankability.

The primary function of racking is to provide a rock-solid foundation that can withstand decades of wind, snow, and UV radiation. A failure here could mean catastrophic roof damage and a total loss of the asset. Skimping on racking introduces massive project risk, potentially leading to failed structural reviews, costly redesigns, or system failure years down the road.

Types of Mounting Systems and Their Applications

The right mounting system is dictated entirely by your project site. A thorough site assessment is the most critical first step.

- Pitched Roof Mounts: The standard for most homes, these systems use rails and attachments that bolt directly to the roof's rafters.

- Flat Roof Mounts: Often use a ballasted design with concrete blocks to hold the array down without roof penetrations, allowing for an optimized tilt angle.

- Ground Mounts: Ideal for large-scale projects with open land, providing complete freedom to orient the array for maximum production.

- Single-Axis Trackers: Typically used in utility-scale solar farms, these systems follow the sun's path to significantly increase energy production and project ROI.

Critical Factors for Procurement and Installation

For professionals managing procurement and installation crews, the decision goes beyond the mount type. Material choices, code compliance, and logistics are where projects either run efficiently or get bogged down in expensive headaches.

Pro Tip: A well-chosen racking system does more than just hold up solar panels—it speeds up your install, simplifies logistics, and guarantees the array will safely generate power for its entire life. Overlooking racking is one of the most common and costly mistakes in project planning.

The material itself is a key consideration. Aluminum is standard for rooftops due to its lightweight and corrosion-resistant properties. Galvanized steel provides the strength needed for large ground-mounts and projects in high-wind regions.

Site Assessment Checklist for Racking Selection

Before ordering racking, a thorough site assessment is essential for code compliance and system longevity.

- Structural Analysis: Can the roof or ground handle the dead load of the array plus the live loads from wind and snow? A structural engineer's approval is often required.

- Wind and Snow Load Requirements: What are the specific wind speed and snow load values required by local building codes? Refer to the ASCE 7-16 standard.

- Local Permitting and Codes: Are there specific setback rules, height limits, or other permitting hurdles for the mounting system?

- Logistics and Site Access: How will you get long rails and heavy hardware to the job site? Ensure a clear path for delivery trucks and equipment.

For Procurement: Streamline your process by working with a distributor like Portlandia Electric Supply that offers bundled freight and kitted racking solutions. This approach handles the sourcing of dozens of small parts, ensuring everything you need arrives in one shipment, cutting labor costs and preventing delays caused by a single missing component.

Balance of System: The Parts That Connect Everything

While solar panels and inverters are the core, a project's safety and success depend on the Balance of System (BOS) components. This is the connective tissue of your solar array: wiring, conduit, combiner boxes, and disconnects. For installers and engineers, a mastery of BOS is non-negotiable for ensuring a system runs safely, passes inspection, and performs reliably for decades.

Wiring and Conduit

Wiring is the circulatory system of a solar array, carrying DC power from the panels to the inverter. Proper wire sizing, guided by the National Electrical Code (NEC), is critical to prevent voltage drop and mitigate fire hazards. Undersized wiring can overheat and will reduce the system's overall energy output, hurting the project's ROI. Conduit is the armor that protects this wiring from physical damage, moisture, and UV degradation.

Combiner Boxes and Overcurrent Protection

On larger systems using string inverters, a combiner box safely merges the output from multiple strings of solar panels into a single feed for the inverter. Crucially, the combiner box houses overcurrent protection devices (OCPDs), like fuses or circuit breakers, as required by the NEC to protect each string from fault currents.

- For Installers: Always double-check that your OCPD rating matches the specifications of both the solar panels and the inverter to ensure NEC compliance and safety.

- For Developers: Sourcing pre-wired, UL-listed combiner boxes from a distributor like Portlandia Electric Supply can significantly reduce field labor time and minimize the risk of wiring errors.

Safety Disconnects

Electrical codes mandate a means to safely shut down a solar system. AC and DC disconnects serve this purpose. A DC disconnect is placed between the solar array and the inverter to isolate the high-voltage DC circuits for maintenance. The AC disconnect is installed between the inverter and the building's electrical panel, providing a clear way to cut the flow of AC power.

Compliance Watchout: Common BOS Inspection Failures

Many failed inspections are due to simple BOS mistakes: improper wire management (sagging cables), using indoor-rated components in outdoor enclosures, incorrect torque on electrical lugs, and failing to properly label disconnects as required by the NEC. These "small" details can cause significant project delays and costly rework.

Ensuring every disconnect is properly rated, clearly labeled, and easily accessible is a critical checkpoint for any electrical inspector.

Integrating Energy Storage and Smart Monitoring

A modern solar array is an intelligent power plant. Adding energy storage and monitoring systems transforms a basic solar setup into a resilient energy asset. For installers, developers, and facility managers, these solar panel system components are essential for maximizing the value of a solar investment.

Energy storage, typically in the form of solar batteries, captures excess power generated during the day for use at night, during peak demand periods, or during a grid outage. Smart monitoring systems act as the brain of the array, providing a constant stream of performance data to identify issues and provide a clear picture of ROI.

The Role of Solar Batteries and Energy Storage

Solar batteries provide true energy independence. Leading brands like BYD, Sungrow, and FranklinWH offer sophisticated lithium-ion battery solutions designed for seamless integration. At the core of every solar battery is the Battery Management System (BMS), an onboard computer that meticulously monitors the battery's health, charge level, and temperature. The BMS is vital for safety and longevity, preventing overcharging and ensuring reliable operation for years.

The push for integrated storage is a significant driver of market growth. The global solar power market continues to expand rapidly, with energy storage playing an increasingly critical role.

Key Decisions for Sizing and Application

For any installer or designer, the conversation about energy storage must start with the client's primary goal, as this dictates the system's size and configuration.

- Backup Power: If the priority is resilience during grid outages, the battery must be sized to power essential loads (refrigerator, lights, well pump, etc.) for a specific duration. This requires a careful load calculation.

- Time-of-Use (TOU) Optimization: In regions with TOU electricity rates, the goal is financial. The battery is sized to store low-cost solar energy during the day and discharge it during high-cost evening peak hours. This "load shifting" strategy can dramatically reduce utility bills.

A battery is not a one-size-fits-all component. Sizing it correctly for either backup or economic optimization is the most important design decision. For a deep dive, see our guide to energy storage systems.

Smart Monitoring for Performance and O&M

Smart monitoring is an indispensable tool for Operations and Maintenance (O&M) providers and asset managers. Monitoring platforms connect to the inverter and other components, delivering real-time and historical performance data.

Data-Driven O&M for Professionals:

- Remote Diagnostics: A robust monitoring platform can flag an underperforming panel or an inverter fault remotely, allowing O&M teams to diagnose issues without a costly truck roll.

- Performance Tracking: Asset managers can track key metrics like kilowatt-hour production against initial projections to verify the system's ROI.

- Proactive Maintenance: Early detection of performance degradation allows crews to schedule proactive maintenance, preventing small issues from becoming costly failures.

Monitoring is the bridge between the physical hardware and the software that proves its long-term value, ensuring the system delivers maximum energy production over its 25-year lifespan.

Common Questions About Solar System Components

This section provides direct, no-nonsense answers to common field questions from installers, developers, and asset owners. The solar industry's rapid growth, with global capacity now exceeding 2.2 terawatts (TW) according to the latest market analysis from IEA-PVPS, makes this practical knowledge more critical than ever.

What Is the Typical Lifespan of Each Solar Component?

Different components have different lifespans and warranties, which is crucial for calculating a project's ROI.

- Solar Panels: Tier 1 manufacturers offer a 25-year power production warranty, guaranteeing a high percentage of original output after 25 years.

- Inverters: A standard string inverter typically comes with a 10 to 12-year warranty, often with an option to extend. Microinverters and power optimizers usually match the panels with a 25-year warranty.

- Racking and Mounting: High-quality aluminum or galvanized steel racking is built to outlast the system, with most reputable brands offering a 20 to 25-year structural warranty.

- Batteries: A battery's life is measured in charge cycles and years. Most modern lithium-ion batteries are warrantied for around 10 years or a set number of cycles, whichever comes first.

Can I Mix and Match Brands for Different Components?

Yes, this is standard industry practice. However, compatibility is non-negotiable. The inverter's electrical specifications must align with the voltage and current of the solar panel strings. Module-level power electronics (MLPE) like optimizers must be compatible with the chosen string inverter.

For procurement managers and EPCs, the real job is making sure every single component on the bill of materials is not only compatible but also UL-listed and up to local code. This is where a knowledgeable distributor saves you massive headaches. They can vet the entire system design before a single box leaves the warehouse, eliminating those compatibility risks.

What Should I Consider When Upgrading or Expanding a System?

Adding panels to an existing array is not always a simple plug-and-play operation. The inverter is the first limiting factor.

Key Upgrade Considerations:

- Inverter Capacity: Does the current inverter have available capacity? If not, you may need to add a second inverter or replace the existing one with a larger model.

- Module Matching: Connecting new, high-wattage panels into a string with older, lower-power panels will result in production loss due to electrical mismatch. All panels in a string should have nearly identical electrical characteristics.

- Code Compliance: A major expansion requires a new permit, which can trigger a requirement to bring the entire system—old and new components—up to current electrical and building codes (e.g., rapid shutdown requirements per NEC).

- Battery Integration: If adding storage, you must confirm the existing inverter is a hybrid model designed for battery management. If not, an AC-coupled battery system or a full inverter replacement will be necessary.

At Portlandia Electric Supply, we don't just sell parts; we deliver complete, pre-vetted system solutions. Our NABCEP-certified experts are here to help you design a new system, map out an expansion, or source a full bill of materials that works right the first time. Request a Bulk Quote and let our team handle the technical heavy lifting.