Understanding Three Phase Power: A Guide for Installers, EPCs, and Developers

For electrical installers, EPCs, facility managers, and developers, three-phase power is the operational backbone for any serious commercial or industrial project. This guide delivers the field-tested knowledge needed to specify, procure, and deploy three-phase systems correctly, avoiding costly design errors and ensuring project profitability. Misunderstanding this foundational technology leads directly to oversized conductors, fried equipment, and crippling downtime.

At its core, three-phase power delivers three distinct alternating currents, each perfectly synchronized but offset by 120°, creating a constant, powerful stream of energy. This is the non-negotiable standard for running high-demand equipment smoothly and efficiently, making single-phase systems inadequate for commercial-scale applications.

Understanding What Three Phase Power Means

Imagine pushing a heavy industrial flywheel. One person pushing alone (single-phase) creates a jerky, inefficient motion. Now, picture three people pushing in a perfectly coordinated rhythm (three-phase)—the wheel spins smoothly, continuously, and with far greater power. That’s the practical difference.

- For Installers: Smooth, constant power means less vibration and wear on expensive motors, reducing callbacks and warranty issues.

- For Facility Managers: Improved load balancing prevents phase imbalances that can trip breakers and lead to costly downtime.

- For Developers: Higher power density allows for smaller, less expensive conductors, directly saving on material costs and improving project ROI.

Developed in the late 19th century, three-phase power became the industry standard for one reason: efficiency. With each of the three currents hitting its peak at a different moment, the total power delivery remains remarkably steady, eliminating the dips and surges inherent to a single-phase setup.

To truly appreciate why this matters, it helps to place it within the broader field of electrical systems to see how it all fits together.

Three Phase Power At a Glance

For project managers and engineers needing a quick reference, this table breaks down the essential attributes of three-phase power and why they matter for making smart decisions on the job.

| Attribute | Description for Project Decision-Making |

|---|---|

| Constant Energy Flow | Guarantees smooth motor operation, reducing mechanical stress and unexpected downtime. Essential for critical machinery like HVAC chillers and manufacturing equipment from brands like Cummins. |

| Balanced Phase Load | Minimizes the risk of overloading one phase, which protects equipment and dramatically extends its operational life. Critical for NEC compliance. |

| Efficient Transmission | Allows for smaller and more cost-effective conductors (wires), directly reducing material and installation costs—a key line item in any project budget. |

This table serves as a solid starting point for initial project planning and equipment specification.

Expert Tip: Three-phase power delivers a continuous, non-pulsating flow of energy. This is a game-changer compared to the "on-off" nature of single-phase power.

This consistency is what reduces vibration, extends the lifespan of motors, and gives you predictable performance from heavy machinery day in and day out.

For project managers and procurement officers, this is a critical detail. Specifying a three-phase service from the utility at the start of a new build is a critical-path item that can save a fortune in what would otherwise become expensive upgrades, rework, and operational delays later.

Benefits For Industrial Applications

In any industrial setting, three-phase power directly translates to lower operational costs. It accomplishes this by boosting energy efficiency while simultaneously cutting down on the material costs for wiring.

- It drives motors with less vibration and delivers much higher starting torque.

- It provides rock-solid voltage even when heavy loads kick on.

- It makes balancing electrical loads across the three phases far simpler, a key requirement of the NEC.

These aren't just theoretical advantages; they deliver measurable ROI in demanding environments like manufacturing plants, warehouses, and data centers.

Choosing the right phase configuration during the initial design phase can dramatically streamline the entire procurement and installation workflow. For example, in large commercial buildings, three-phase power is essential for big HVAC systems, ensuring they can handle peak summer loads without causing voltage drops that affect other equipment.

Getting these fundamentals right sets the stage for everything that follows, from choosing between Wye and Delta connections to performing accurate voltage calculations. It ensures every stakeholder, from the engineer to the accountant, can make informed, cost-effective decisions right from the project’s kickoff.

How Wye and Delta Configurations Work

To really get why three-phase power is the backbone of commercial and industrial work, you have to look at how it’s wired up in the field. The magic of its continuous power delivery comes from its three AC waveforms, each hitting its peak 120 degrees apart from the others. This perfect timing means that as one wave starts to dip, another is already rising to pick up the slack, killing the power gaps you get with single-phase systems.

That smooth, constant flow is non-negotiable for big equipment. But how that power gets delivered comes down to two main wiring setups: Wye and Delta. For any installer, engineer, or PM, knowing the difference isn't just trivia—it's essential for ordering the right gear and designing a system that’s both safe and efficient. These configurations dictate the voltages you can get and whether or not you have a neutral wire to work with.

Introducing the Wye Configuration

The Wye configuration, sometimes called a star connection, is easy to spot. All three phases connect at a single central point, which looks a lot like the letter 'Y'.

That central hub is what creates the neutral wire, and that’s the Wye's biggest selling point. Having a neutral lets the system deliver two different voltages from the same service:

- Phase-to-Neutral Voltage: This is your lower voltage, perfect for standard 120V outlets, lighting, and other small single-phase loads.

- Phase-to-Phase Voltage: This is the higher voltage (like 208V), used to run heavy-duty three-phase motors and machinery.

This two-for-one flexibility makes a Wye connection the standard choice for places like mixed-use commercial buildings, where you need to run the office lights and the massive HVAC system from the same electrical panel. For a deeper dive into these kinds of setups, check out our other articles on energy solutions.

Understanding the Delta Configuration

In a Delta configuration, the three phases are wired together in a series, forming a closed triangle that looks just like the Greek letter delta (Δ). The key takeaway here is that a standard Delta setup has no neutral wire.

This configuration is a specialist, built for one job: delivering serious, high-torque power to machinery.

For the Field Professional: Think of Delta as the pure workhorse for industrial jobs. It’s naturally balanced for three-phase motors, making it incredibly stable for manufacturing equipment, huge pumps, and industrial compressors that need consistent, heavy power.

Without a neutral, a standard Delta system isn't meant to handle single-phase loads like your typical office lighting. Equipment from brands like Cummins or FranklinWH will always specify if they need a Wye or Delta system, and mixing them up is a fast way to fry expensive gear.

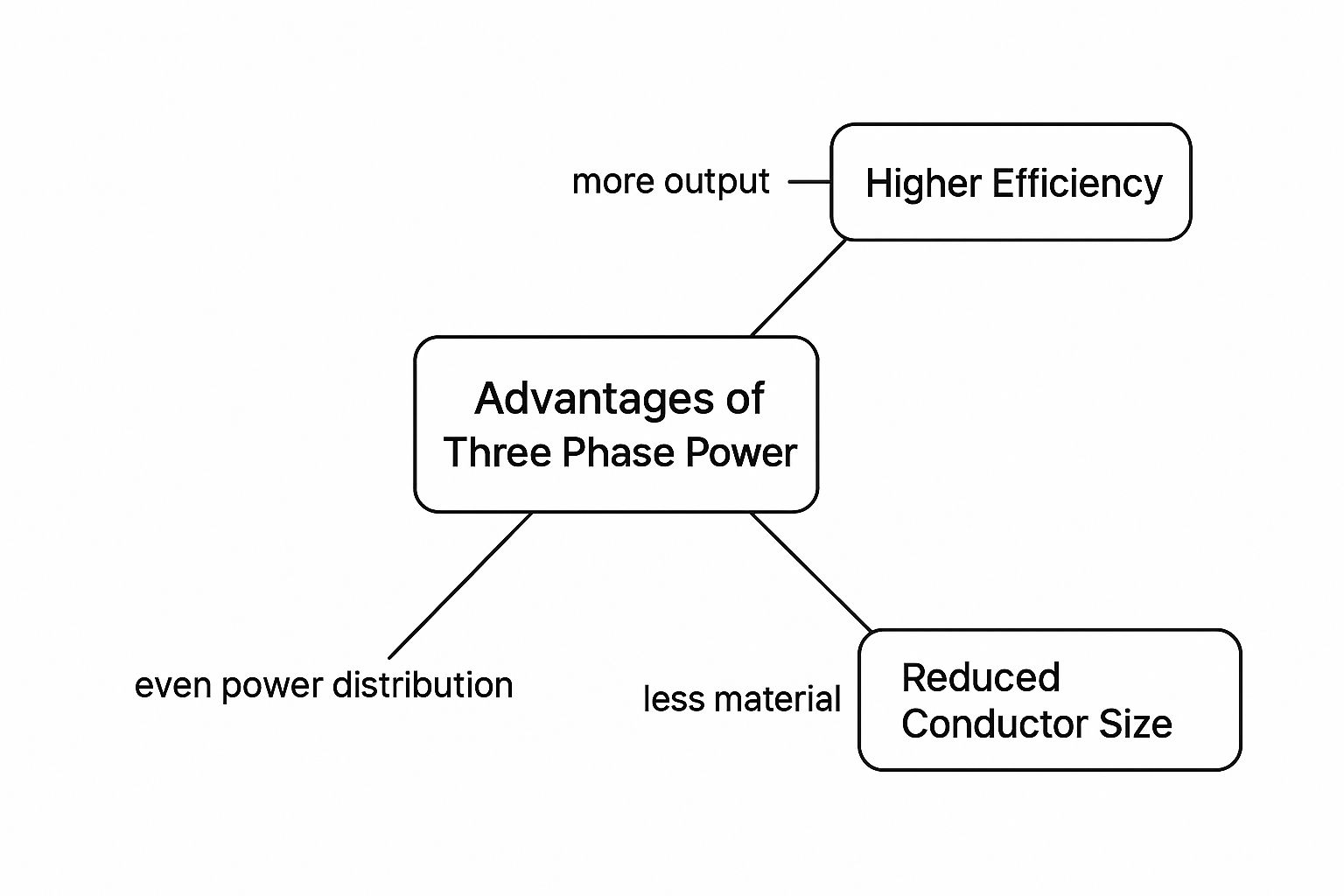

This infographic breaks down the core benefits that these wiring setups help deliver.

As you can see, the fundamental design of three-phase systems leads straight to better efficiency, balanced loads, and even savings on copper since the conductors can be smaller.

Wye vs. Delta: Key Decision Points

Choosing between Wye and Delta isn't a matter of preference; it’s driven entirely by the load requirements of the project. While the electrical engineer makes the final call, every stakeholder should understand the implications.

| Configuration | Primary Use Case | Key Feature | Common Voltages (US) |

|---|---|---|---|

| Wye (Star) | Commercial buildings, data centers, mixed-use facilities | Provides a neutral wire for dual-voltage capability | 120/208V, 277/480V |

| Delta | Industrial plants, manufacturing, large motor loads | No neutral wire, optimized for balanced three-phase loads | 240V, 480V, 600V |

For a facility manager or developer, seeing a Wye service on a one-line diagram means the building is ready for both general-purpose electricity and heavy machinery. Spotting a Delta symbol, on the other hand, tells you that the system was purpose-built for industrial-grade equipment. Knowing this difference is crucial for buying the right equipment and planning for the long haul.

Comparing Single Phase and Three Phase Power

Choosing between a single-phase and three-phase utility service is one of those foundational decisions that sets the entire trajectory of a project. It directly impacts budget, scope, and how well the site performs for years to come.

For developers, getting this right at the blueprint stage prevents eye-watering infrastructure costs down the line. For installers, it’s all about safe load balancing and staying compliant with NEC code. This isn’t just about the number of wires; it's about matching the power supply to the real-world demands of the job.

What’s the Practical Difference?

Let's cut through the textbook definitions.

Single-phase power is what you find in almost every home and small office. It runs on two wires—a power wire and a neutral—delivering electricity in a single wave. It’s perfectly capable of running your lights, computers, and standard appliances.

Three-phase power, on the other hand, is the workhorse of the commercial and industrial world. It uses three separate power wires, each delivering an electrical wave that peaks at a different moment. The result is a smooth, constant, and far more powerful stream of energy.

This fundamental difference in delivery changes everything—from the equipment you can run to how efficiently your facility operates.

Application and Load Capacity

The most obvious dividing line is what each system can actually power. Single-phase is great for loads up to about 7.5 kVA, which covers your typical home or a small commercial storefront with basic needs.

Three-phase is built for the heavy hitters. You absolutely need it for:

- Large HVAC Systems: Those big rooftop air conditioners and chillers need the high starting torque and stable power only three-phase can deliver.

- Manufacturing Machinery: Motors on everything from conveyor belts to CNC machines run smoother, cooler, and more efficiently on three-phase.

- EV Charging Depots: Trying to power a bank of DC fast chargers on a single-phase service is a non-starter. The load is simply too immense.

- Data Centers: Constant, clean, and reliable power is non-negotiable for servers and cooling systems. Three-phase is the only option.

Compliance Watchout for Developers: Specifying three-phase service from the utility at the start of a new commercial build is a critical-path item. Trying to upgrade a site from single-phase to three-phase later isn’t a simple service call. It means trenching, new transformers, and a bureaucratic dance with the utility that can cause massive delays and budget overruns.

Single Phase vs Three Phase for Project Planners

For anyone speccing out a new project—from planners and architects to the installers on the ground—this table breaks down the key decision points. It’s a practical guide for matching the utility service to the project’s needs.

| Factor | Single Phase Power | Three Phase Power |

|---|---|---|

| Typical Application | Residential homes, small offices, light commercial | Industrial facilities, data centers, large commercial buildings |

| Power Delivery | Pulsating, single wave of AC power | Continuous, smooth flow from three overlapping AC waves |

| Efficiency | Lower efficiency for high-demand loads | Significantly more efficient for large motors and machinery |

| Conductor Size | Requires larger, more expensive wires for the same power output | Can deliver more power with smaller, less costly conductors |

| Equipment Cost | Single-phase motors are generally less expensive | Three-phase motors and equipment can be more costly upfront |

| Installation Cost | Lower initial installation cost and complexity | Higher installation cost due to more complex wiring and panels |

| Voltage Options | Typically 120V or 240V | Common voltages include 208V, 240V, and 480V |

At the end of the day, it all comes down to the load. A small law office running computers and coffee makers will never justify the cost of a three-phase service. But if the plan includes any large motors, compressors, or heavy machinery, you have to factor in three-phase from day one.

Getting this right isn't just about meeting today's needs; it's about future-proofing the facility for whatever comes next.

Key Advantages for Commercial and Industrial Projects

For the folks managing projects—EPCs, developers, facility managers—three-phase power isn't just an abstract electrical concept. It's about the bottom line. It directly impacts project budgets, timelines, and the long-term cost of keeping the lights on.

This is the real "why" behind specifying three-phase service for any serious commercial or industrial build. The advantages come down to efficiency, power density, and making heavy equipment run better. We're not talking about minor tweaks; these are fundamental improvements over single-phase systems that deliver a measurable return on investment.

Higher Power Density and Reduced Costs

The most immediate win with three-phase power is higher power density. What that means in the real world is you can move a whole lot more power using smaller, less expensive wires compared to a single-phase system doing the same job.

For any large-scale build, this is a direct cut to your material costs. You need less copper for the entire installation, from the main service entrance right down to the final equipment hookups. That efficiency is a huge cost-saver, especially when you're talking about the miles of wire in a large facility. For companies in the electrical trade, knowing this is key to building competitive bids and effective marketing strategies for electrical contractors.

A huge benefit here is the sheer reduction in material. You're using three live wires instead of a bulkier two-wire setup for the same power, which can cut your copper usage and infrastructure costs by nearly half. In fact, these systems can slash the amount of wire needed by around 50% without giving up any power delivery.

Procurement Pro Tip: When you're sourcing materials, the savings on smaller conductors get even better with bulk buys and smart shipping. At Portlandia Electric Supply, we help clients bundle smaller-gauge wires with other project components into a single, cost-effective shipment to stretch that material budget. Our PowerLink service can even connect you with qualified local installers to manage the job.

Greater Efficiency and Lower Energy Loss

Three-phase systems are just plain more efficient. That constant, smooth flow of power means less energy gets wasted as heat in your wiring and equipment. This isn't just a technical footnote—it shows up as a smaller number on the monthly utility bill.

Over the life of a manufacturing plant, a data center, or a big commercial building, these savings add up in a big way.

- Reduced Resistive Loss: With the load spread across three conductors, the current in each wire is lower. Less current means less energy lost to heat.

- Optimized Motor Performance: Three-phase motors are champs at converting electrical energy into actual work, not wasted heat.

- Improved Power Factor: A balanced three-phase system typically has a much better power factor, which helps you dodge expensive penalties from utility companies.

This is exactly why any facility with a serious energy appetite, from industrial freezers to massive server farms, runs on a three-phase supply. The long-term operational savings are too big to pass up.

Superior Performance for Large Motors

Finally, when it comes to running big motors, nothing beats three-phase power. Single-phase motors need special capacitors and circuits just to get them spinning. Three-phase motors? They're self-starting.

The rotating magnetic field created by the three power waves naturally gets the motor’s rotor turning. It provides powerful starting torque right out of the gate without any extra parts. This leads to some serious practical benefits:

- Increased Reliability: Fewer starting parts means fewer things that can break.

- Longer Motor Lifespan: That smooth power delivery reduces vibration and mechanical stress, so the motor lasts longer.

- Simpler Design: Three-phase motors are often smaller, tougher, and less complicated than their single-phase cousins.

For a facility manager, this translates to less downtime, lower maintenance bills, and equipment you can actually depend on, whether it's an HVAC chiller, an elevator, or a critical piece of factory machinery.

Where Three-Phase Power Is Used in the Real World

Theory is great, but seeing where three-phase power is absolutely non-negotiable is what really matters on the ground. For project planners, facility managers, and anyone speccing a job, this is where principles turn into profit—or painful, costly failures.

Let's look at a few mini-case studies. These show exactly why getting the right power service from day one is a make-or-break decision for any high-demand facility. Trying to skimp with an inadequate power source isn't just a bad idea; it’s a direct path to fried equipment, chronic downtime, and a hemorrhaging budget.

Data Centers: The Need for Uninterrupted Power

For a data center, power isn't a utility; it's the lifeblood. We're talking about facilities packed with thousands of servers, massive cooling systems, and networking gear that demand a constant, clean, and totally reliable stream of energy.

- Key Equipment: Server racks, HVAC chillers, uninterruptible power supplies (UPS), and power distribution units (PDUs) are all built for three-phase.

- The Cost of Failure: Even thinking about using a single-phase supply is out of the question. The huge, constantly shifting power draws would be impossible to handle. A single flicker or dip from an unbalanced system could corrupt data, kill hardware, and trigger catastrophic downtime—costing a company millions per hour. A three-phase Wye setup (like 277/480V) is the industry standard for a reason.

Manufacturing and Industrial Facilities

Walk into any manufacturing plant, and you'll see that every machine—from the conveyor belt to the robotic welder—is a profit center. These places are filled with heavy-duty motors that need a massive kick of starting torque and are expected to run efficiently for thousands of hours without a hiccup.

Expert Insight for Facility Managers: Three-phase motors are simply tougher and more reliable than their single-phase cousins. They start on their own and run smoother, which means less mechanical stress, less vibration, and fewer things that can break. That translates directly to lower maintenance bills and less time spent on unscheduled shutdowns.

A Delta configuration is often the go-to here. It delivers the stable, high-torque power needed to run heavy equipment like compressors, lathes, and pumps. Trying to power this machinery with single-phase would mean adding complex, failure-prone starting capacitors, leading to constant burnouts and production grinding to a halt.

Commercial Buildings and HVAC Systems

Big commercial buildings, whether they're office towers or shopping malls, rely on three-phase power for their most basic functions. The biggest energy hog is usually the HVAC system, but elevators and large-scale lighting are right behind it.

- Equipment Powered: Rooftop HVAC units, chillers, air handlers, elevators, and escalators.

- The Financial Impact: These systems have enormous motors that are constantly cycling on and off. A three-phase supply can handle those huge inrush currents without causing voltage to sag, which would make the lights flicker or mess with other tenants' equipment. Using the wrong service leads to bad climate control, equipment that dies early, and sky-high energy bills from running inefficiently.

And when the grid goes down, having the right backup is critical. For a deep dive into sizing and selecting the right systems for these demanding loads, check out our guide to commercial and industrial generators.

Electric Vehicle (EV) Charging Depots

The EV boom has created a brand-new, power-hungry application: DC fast-charging depots. A single DC fast charger can pull over 150 kW of power, and a single depot might have dozens of them running at once.

- Equipment Powered: Multiple Level 3 DC fast chargers from brands like Sungrow or Fronius.

- The Inescapable Need: A single-phase service can't even begin to handle this kind of demand. It's a total non-starter. Three-phase power is the only practical way to deliver the immense, sustained energy needed to charge multiple cars quickly. Any developer planning new charging infrastructure has to get the utility involved early to secure a three-phase hookup—it's the absolute foundation of the entire project.

Practical Considerations for Your Project

Knowing the theory behind three-phase power is one thing, but making it work safely and efficiently in the real world is another game entirely. For any installer, electrician, or project manager on the ground, this is where the details really matter.

A successful installation is about much more than just connecting wires. It’s about careful planning around load balancing, selecting the correct voltage for the job, and sticking to the code. Getting these things right is what separates a smooth, reliable project from a costly headache.

Balancing Loads Across Phases

One of the first things you learn on the job is the importance of load balancing. This just means spreading the electrical demand as evenly as you can across all three phases. An unbalanced system isn't just inefficient—it's dangerous and a fast track to fried equipment.

When one phase is pulling way more current than the others, things start to go wrong. Wires overheat, voltage can dip, and motors will burn out long before their time. By balancing the load, you make sure no single part of the system is overworked, keeping everything stable and extending its lifespan. This is absolutely critical in buildings that mix and match single-phase and three-phase equipment.

Understanding Common Voltage Standards

You have to get the voltage right from the very beginning. In the U.S., you'll run into a few standard three-phase voltages, and each one has its place:

- 208V/120V: This is what you’ll find in most commercial buildings. It’s a Wye setup that gives you 120V for standard outlets and lights, plus 208V to run three-phase equipment.

- 480V/277V: The standard for industrial plants and big commercial sites. The higher 480V is perfect for heavy machinery, while the 277V leg is a super-efficient option for powering large-scale lighting systems.

- 240V Delta: You'll see this in some smaller commercial shops or for specific machines that don't need a neutral wire.

Choosing the right voltage upfront prevents the expensive mistake of ordering equipment that won't work with the building's electrical service. It's a foundational step in project design, especially when you start bringing in more advanced gear like the ones we cover in our guide to energy storage systems.

Adhering to NEC Code and Safety

Following the code isn't just a good idea; it's the law. The National Electrical Code (NEC) lays out the rules for everything—conductor sizes, breakers, grounding, you name it. Sticking to the NEC ensures the system is safe for the equipment and, more importantly, for the people around it.

Critical Mistake: Incorrect Phase Rotation

A classic—and very damaging—mistake is getting the phase rotation wrong. Three-phase motors are built to spin in one direction. If you accidentally swap the phase sequence during wiring (like connecting A-C-B instead of A-B-C), the motor will run backward. For things like pumps, fans, and conveyor belts, this can cause instant, catastrophic damage. Always double-check your work with a phase sequence meter before you power up any motor.

Common Questions from the Field

Let's get straight to the practical questions that come up on the job site when you're dealing with three-phase power. Here are the no-fluff answers installers, project managers, and building owners need to get things right from the start and avoid expensive headaches.

Can I Run Single-Phase Equipment on a Three-Phase System?

You absolutely can, and it's done all the time. This is one of the key benefits of a Wye-configured three-phase system, which is the standard setup you'll find in nearly every commercial building.

A Wye system gives you a neutral wire, which is your ticket to tapping into a single phase to get standard voltages like 120V or 277V. This is exactly how a building can run a huge three-phase HVAC unit off the same service that powers the 120V outlets for office computers. The critical part? Make sure those single-phase loads are spread out evenly across the three phases. If you don't, you create an unbalanced system that can cause serious overheating and burn out equipment.

Is Three-Phase Power More Dangerous Than Single-Phase?

Not inherently, but the stakes are higher and it demands a pro's touch. The main difference is the voltage. We're often talking about 480V between phases, which packs a much bigger punch than the 120/240V in a typical home.

The core safety rules don't change, though. Proper grounding, wearing the right personal protective equipment (PPE), and following the NEC (National Electrical Code) to the letter are all non-negotiable. But because of the higher energy potential and complexity, three-phase systems should only be touched by qualified, licensed electricians. No exceptions.

What’s the Real Cost to Upgrade to Three-Phase?

Moving a building from single-phase to three-phase is a major project, not a simple flip of a switch. The final bill can swing wildly depending on a few key factors:

- Utility Proximity: How far is your property from the nearest three-phase utility line? If they have to trench and run new lines for a significant distance, that cost adds up fast.

- On-Site Infrastructure: You're not just getting new wires. You'll need a new meter base, a three-phase main panel, and possibly new transformers to handle the service.

- Permitting and Fees: Your local jurisdiction and the utility company have their own fee structures and permitting hoops to jump through.

A Note for Developers & Property Owners: Be prepared for a cost anywhere from a few thousand dollars to well over $50,000. It is always, always cheaper to spec three-phase service during new construction than it is to retrofit an existing building.

How Can I Tell if My Building Has Three-Phase Power?

You can usually spot it with a quick visual check, no tools required. First, open the main electrical panel. A single-phase panel has two main bus bars running down the center, while a three-phase panel will have three.

Another dead giveaway is the main circuit breaker—it'll be a big, three-pole breaker that looks like three breakers fused together. If you can see the utility service drop, you'll typically see four thick wires coming into a three-phase building (three "hot" lines and one neutral), while a single-phase service usually only has three.

Ready to spec the right components for your next three-phase project? Portlandia Electric Supply offers a massive in-stock inventory of panels, transformers, and all the balance-of-system gear you need, with expert support and fast, nationwide logistics to keep your job on track. Request a Bulk Quote today and see how we can streamline your procurement process.