The Best Solar Panel Cleaning Equipment: A Project-Based Guide for Installers & Asset Managers

Learn About the Best Solar Panel Cleaning Equipment

For solar installers, EPCs, and asset managers, choosing the "best" solar panel cleaning equipment is a critical decision driven by project scale, site conditions, and operational budget. The right gear isn't just about cleaning—it's about protecting asset value, ensuring PPA compliance, and maximizing the return on investment for every project, from a 10kW residential rooftop to a 100MW utility-scale farm.

This guide provides a clear decision-making framework for selecting the right equipment. We'll segment the options by project type, break down the real-world operational factors, and show how strategic equipment procurement can directly boost your project's bottom line.

This article is for:

- Residential & Commercial Installers: Learn which manual tools maximize efficiency and protect client warranties.

- EPCs & Developers: Understand the breakeven point for investing in semi-automated vs. fully robotic systems.

- Asset Managers & Procurement Officers: Get a framework for calculating the Total Cost of Ownership (TCO) and justifying cleaning as a revenue-assurance activity.

Choosing the Right Solar Panel Cleaning Equipment

The equipment you choose directly impacts labor costs, operational efficiency, and the long-term performance of your solar panels. This isn't a one-size-fits-all decision. A residential installer needs portable, affordable tools safe for sloped roofs, while an EPC overseeing a utility-scale project in an arid region must prioritize waterless operation and a low levelized cost of cleaning (LCOC).

Your decision-making is driven by project-specific variables:

- Water Scarcity & Cost: A primary concern in dry regions, driving the need for waterless or low-water solutions.

- Labor Costs & Availability: The cost and skill level of local crews heavily influence the ROI of automation.

- Soiling Rates: The financial impact of lost energy production dictates cleaning frequency and technology choice.

- Total Cost of Ownership (TCO): A comprehensive calculation including CAPEX, maintenance, logistics, and the value of recovered energy.

This guide breaks down the equipment categories—manual, semi-automated, and fully robotic—through the lens of maximizing project ROI.

Expert Tip: The "best" equipment is the one that delivers the lowest Levelized Cost of Cleaning (LCOC) for your specific site. This calculation must include the equipment's price, labor, water, and the value of the energy recovered after cleaning. A lower LCOC directly translates to a higher project IRR.

To start, the matrix below maps each equipment category to its ideal project scale and highlights the key decision-making factors. For a deeper dive into panel performance, check out our articles on solar panels and related technologies.

Equipment Selection Matrix by Project Type

This matrix provides a quick-glance guide to match equipment to your project, grounding your decision in the practical realities of your site and ensuring a financially sound choice.

| Equipment Category | Best For (Project Scale) | Primary Use Case | Key Decision Factors |

|---|---|---|---|

| Manual Tools | Residential & Small Commercial (<500kW) | Rooftops, small ground-mounts, and difficult-to-access arrays. | Low upfront cost, portability, accessibility, and operator safety (fall protection). |

| Semi-Automated Systems | Large Commercial (500kW - 5MW) | Large flat rooftops and medium-sized ground-mount projects. | Balance of labor efficiency and capital cost, water usage, and maneuverability. |

| Fully Automated Robotics | Utility-Scale (>5MW) | Large, uniform ground-mount solar farms in high-soiling, water-scarce areas. | Waterless/low-water operation, cleaning speed (MW/hour), and minimizing ongoing labor. |

Manual Cleaning Tools for Installers and Small Projects

For residential installers and contractors on smaller commercial jobs, manual cleaning tools are the operational workhorse. They offer a low-cost, effective, and portable solution to maintain asset performance. However, professional-grade cleaning is a calculated process that directly impacts on-site efficiency and the long-term health of the solar panels.

A professional manual cleaning kit consists of three core components: the water-fed pole, the brush head, and the water source.

The water-fed pole is the cornerstone of the operation, typically made from aluminum or carbon fiber for safe reach on rooftop arrays. The choice involves a trade-off between length, rigidity, and weight. A carbon fiber pole offers a lighter, stiffer option, reducing operator fatigue and improving control on multi-story jobs. For single-story homes or accessible ground-mounts, a durable aluminum pole is a cost-effective alternative.

Choosing Brushes and Water Systems

The brush head is where you protect the asset. Modern solar panels feature a delicate anti-reflective (AR) coating crucial for maximizing sunlight absorption. Using an abrasive brush can permanently scratch this coating, causing irreversible performance loss and voiding warranties.

Critical Compliance Note: Always use a non-abrasive, soft-bristle brush specifically designed for solar panel cleaning, such as flocked nylon or boar's hair. These materials are tough enough to remove grime but gentle enough to protect the vital AR coating. Using the wrong brush can easily void the panel manufacturer's warranty.

The final element is the water itself. In regions with hard water (high mineral content), evaporation leaves behind mineral deposits that can re-soil panels and even etch the glass over time. This is why a Deionized (DI) Water System is a critical investment for professionals. These portable units use resin filters to remove all total dissolved solids (TDS), ensuring a spot-free finish.

- When is a DI System Necessary? For any professional installer in an area with a water TDS reading over 100-150 parts per million (PPM), a DI system is a non-negotiable tool for delivering a professional, warranty-compliant clean.

- When Can You Skip It? For a homeowner in an area with naturally soft water (low TDS), a DI system is likely overkill for occasional cleaning.

Practical Scenarios for Manual Equipment

- The Suburban Two-Story Home: For a 10kW array on a pitched roof, the ideal kit is a 30-40 foot carbon fiber water-fed pole for superior reach and control. Paired with a soft-bristle brush and a portable DI water system, this setup guarantees a flawless, spot-free finish that justifies a professional service fee.

- The Small Rural Ground-Mount: For an accessible 5kW system, a sturdy 18-foot aluminum water-fed pole is sufficient. If local well water is tested and found to be soft, connecting directly to a garden hose can significantly reduce equipment overhead.

By matching your pole, brush, and water purification to the job, you enhance workflow efficiency while protecting your client's investment. Portlandia Electric Supply allows contractors to bundle these essential cleaning tools with their panel and inverter orders, streamlining purchasing and saving on freight.

Evaluating Robotic And Semi-Automated Cleaning Systems

For commercial and utility-scale projects, transitioning from manual cleaning is a financial and operational imperative. As arrays scale into megawatts, semi-automated and fully robotic systems become the only logical choice. They represent the upper tier of the best solar panel cleaning equipment, designed to clean massive sites with unmatched speed and consistency.

The market for this equipment is expanding rapidly, projected to hit USD 142.9 million by 2025 with a 14.9% CAGR. This growth is driven by a simple fact: automation slashes labor and water consumption, boosting efficiency and lowering long-term operational costs. You can learn more about these market trends and their industry implications.

Key Evaluation Criteria For Automated Systems

For procurement officers and developers, the choice between systems hinges on core metrics that directly impact TCO and performance.

- Water Usage: Fully robotic systems from pioneers like Ecoppia are often water-free, using microfiber brushes and controlled air blowers—ideal for arid regions. Semi-automated systems use water but are far more efficient than manual methods.

- Cleaning Speed: A critical ROI metric, measured in acres or megawatts per hour. The goal is to match cleaning speed to the site's soiling rate to maintain peak production.

- Power Source: Fully automated robots are typically self-powered via their own solar panel and battery. Semi-automated systems often draw power from a vehicle or generator, introducing an ongoing fuel cost.

- System Compatibility: It is critical to confirm that the cleaning system is compatible with your project’s specific mounting and tracking technology (e.g., fixed-tilt, single-axis tracker, or a custom rooftop design).

-

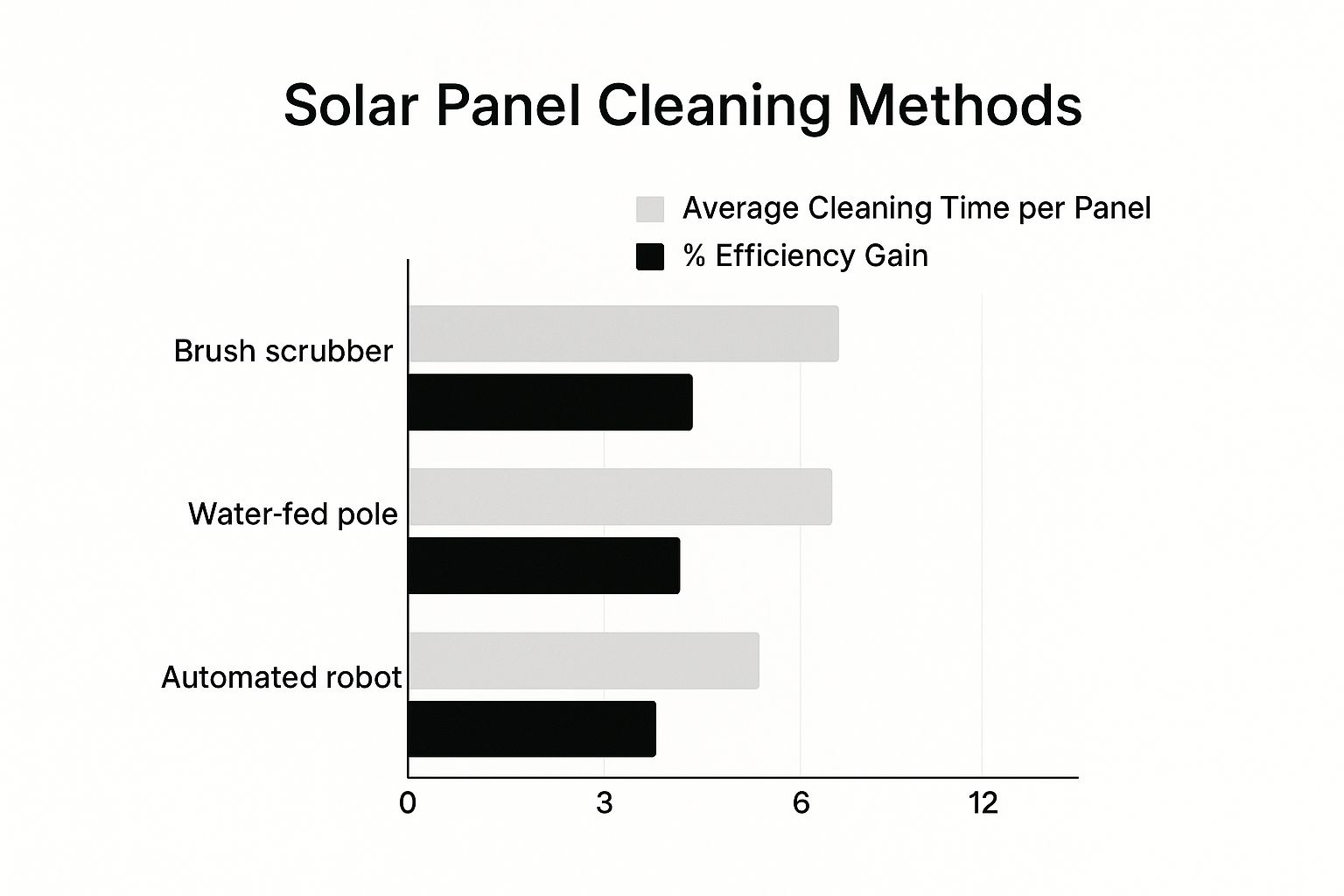

- Automated robots deliver a massive leap in efficiency, dramatically reducing the time required compared to manual methods.

The True Cost Of Ownership

Focusing solely on the upfront price of an automated system is a common pitfall. A proper financial analysis must account for the entire lifecycle cost.

Expert Insight for Procurement Officers: "When evaluating robotic systems, look beyond the purchase price. Your Total Cost of Ownership model must include projected maintenance, spare parts availability, operator training, and any software subscription fees. A cheaper system with high maintenance needs and poor support can ultimately cost more than a premium, reliable solution."

This holistic approach is the only way to make a true apples-to-apples comparison and understand the long-term financial impact on your project.

Robotic vs Semi-Automated Systems: A Feature Comparison

To help guide your decision, this table breaks down the core differences between fully automated and semi-automated systems.

| Feature | Fully Automated Robotic System | Semi-Automated System |

|---|---|---|

| Labor Requirement | Minimal (for monitoring and maintenance) | Small crew (1-3 operators) |

| Water Usage | Typically waterless | Low to moderate water usage |

| Operational Control | Autonomous, cloud-based scheduling | Manual operation by a trained crew |

| Upfront Cost | High | Medium |

| Ideal Project Size | Utility-Scale (>10MW) | Large Commercial & Small Utility (1MW-10MW) |

| Flexibility | Fixed to a specific array | Highly mobile, can service multiple sites |

For an EPC building a 100 MW solar farm in a desert, a fleet of waterless, fully automated robots is the clear choice. The high upfront investment is justified by massive long-term savings in water and labor. In contrast, a company managing a portfolio of 5 MW commercial rooftop projects would benefit from a mobile, vehicle-mounted semi-automated system that balances capital investment and operational flexibility.

Portlandia Electric Supply can help you source and procure both types of systems, ensuring the technology aligns with your project's financial and environmental goals.

How Soiling Impacts Your Solar Project ROI

Viewing the best solar panel cleaning equipment as a mere operational expense is a strategic error. It is a direct driver of revenue and a powerful risk mitigation tool. For developers, asset owners, and EPCs, quantifying the financial drag from soiling—the accumulation of dust, pollen, and grime—is essential for protecting a project's long-term value.

Soiling blocks sunlight, causing a measurable drop in energy production. In dry regions like the U.S. Southwest, soiling losses can reach 15-20%, and in extreme cases of neglect, up to 50%.

The Financial Consequences of Neglect

This drop in energy yield creates immediate and cascading financial problems.

- PPA Contract Compliance: Many Power Purchase Agreements (PPAs) include performance guarantees. Consistent underperformance due to soiling can lead to contractual penalties or default, jeopardizing the project's financial stability.

- Reduced Revenue Streams: A 10% output reduction on a 10MW solar farm can result in hundreds of thousands of dollars in lost annual income, directly eroding the project's internal rate of return (IRR).

- Inaccurate Financial Modeling: Failing to accurately account for soiling losses during development creates a gap between investor expectations and actual project delivery.

-

For Asset Managers: Soiling is a quantifiable risk that must be managed with the same rigor as equipment failure. A proactive cleaning strategy is not a cost center; it's a revenue assurance activity.

- The global solar panel cleaning market, valued at USD 1.43 billion in 2024, is expected to nearly double by 2032, reflecting a growing understanding of these financial realities. As detailed in this detailed industry report, the industry is shifting toward automation as cleaning becomes recognized as essential asset management.

- From Reactive Cost to Proactive Investment

- When framed as a proactive investment, the question shifts from "How much does it cost?" to "What is the return on this investment?" The answer lies in comparing the cost of a cleaning solution against the value of the recovered energy production. A proper cleaning regimen ensures that the financial and environmental advantages of solar power energy are fully realized over the asset's life.

- Real-World Scenarios and Equipment Recommendations

- Field conditions dictate the right tools. To make a smart procurement decision, you must analyze the real-world demands of your project, from system size and location to labor costs and water access. Here are three common project scenarios with clear equipment recommendations you can source through Portlandia Electric Supply.

- For The Residential Installer in a High-Pollen Area

- Scenario: A residential contractor cleans a 12kW array on a two-story home in a region with heavy seasonal pollen, such as the Pacific Northwest. The primary challenge is removing the sticky pollen film without leaving mineral spots from hard water, all while ensuring operator safety on a pitched roof.

- Equipment Recommendation:

- Carbon Fiber Water-Fed Pole (30-45 ft): A lightweight but rigid carbon fiber pole is essential for control and reducing operator fatigue.

- Soft-Bristle, Non-Abrasive Brush: A soft, flocked bristle brush can gently scrub away the film without scratching the panel's anti-reflective coating and voiding the warranty.

- Portable Deionized (DI) Water System: This is non-negotiable for a professional finish. A DI system ensures a spot-free dry, differentiating your service.

-

Pro Tip for Installers: Bundle your cleaning kit with your next panel order from Portlandia Electric Supply. We can consolidate your DI system, poles, and brushes on the same freight shipment, simplifying your purchasing and ensuring your crew is always ready for maintenance.

- For The Commercial EPC on a Rooftop Project

- Scenario: An EPC manages a 5MW commercial rooftop installation on a large warehouse in an industrial zone. The decision is whether to purchase a semi-automated cleaner or subcontract the cleaning.

- This is a breakeven analysis. Compare the total cost of owning a semi-automated system (CAPEX, labor, maintenance) against the recurring cost of a subcontractor. A semi-automated system often pays for itself within 18-24 months and provides complete control over the cleaning schedule.

- Equipment Recommendation:

- Vehicle-Mounted Semi-Automated System: A system mounted on a small utility vehicle allows a two-person team to clean the 5MW array far more efficiently than a manual crew, striking the right balance between capital investment and labor efficiency.

- Actionable Next Step: Request a quote for a semi-automated system from Portlandia Electric Supply. Our team can help you run TCO models to make a data-driven decision and explore other solar energy solutions for your project.

- For The Utility-Scale Asset Manager in an Arid Environment

- Scenario: An asset manager oversees a 100MW ground-mount solar farm in the U.S. Southwest, where water is scarce and expensive, and dust requires frequent cleaning to meet PPA guarantees.

- Water scarcity and sheer scale make manual or water-based systems operationally and financially unfeasible. A fully autonomous, waterless solution is the only viable path.

- Equipment Recommendation:

- Fleet of Waterless Robotic Cleaners: Deploying a fleet of autonomous robots is the definitive solution. These units, like those from industry leaders such as Ecoppia, operate nightly, powered by their own solar panels. They use microfiber brushes and airflow to remove dust without water, ensuring maximum output while complying with environmental standards.

- Actionable Next Step: Contact a Portlandia Electric Supply project expert to discuss sourcing and logistics for a utility-scale robotic cleaning fleet. We leverage strategic partnerships with top automation vendors to manage procurement and delivery for projects of any size.

- Getting the Right Gear to Your Job Site

- Identifying the best solar panel cleaning equipment is only half the battle; getting it to your job site without logistical headaches is the other. At Portlandia Electric Supply, we act as your project partner to streamline this process, bridging the gap between equipment selection and on-time, on-budget delivery.

- Deep Inventory and Direct Vendor Access

- For manual cleaning, we maintain a deep inventory of professional-grade water-fed poles, non-abrasive brushes, and portable DI water systems, ready for fast shipment. For larger projects, we leverage direct partnerships with top vendors in robotic and semi-automated cleaning to source the most effective technology for your site.

-

Our Promise to Your Project: We provide an end-to-end procurement and logistics solution designed to reduce friction, shorten lead times, and ensure your team has what it needs, when they need it.

- Bundled Freight and PowerLink Services

- Our bundled freight optimization allows you to consolidate your cleaning equipment with your main project Bill of Materials (BOM)—panels, inverters, racking—for significant savings on shipping and simplified logistics.

- Additionally, our PowerLink service connects project owners with our network of vetted, local installers who are fully equipped for professional cleaning and maintenance.

- The need for these integrated services is growing. The solar panel cleaning market, valued at USD 1.12 billion in 2024, is projected to reach nearly USD 2.98 billion in the next decade, driven by the critical need to protect the ROI of an expanding global solar fleet. You can explore more on this market's growth trends at Meticulous Research.

- Frequently Asked Questions

- Here are field-tested answers to the most common questions we hear from homeowners, installers, and asset managers about solar panel cleaning.

- How Often Should I Clean My Solar Panels?

- The answer depends entirely on your site. A bi-annual cleaning (every six months) is a solid baseline for most residential and commercial systems in typical climates.

- High-Soiling Areas: In dusty, agricultural, or industrial zones, cleaning may be needed quarterly or more frequently. Monitor your system's output; a noticeable dip is a clear signal.

- Low-Soiling Areas: In locations with regular rainfall and low airborne particulates, a single annual cleaning may suffice.

- Is Rain Enough to Clean Solar Panels?

- Rain can wash away loose dust, but it is no substitute for a proper cleaning. It cannot remove stubborn grime like pollen, bird droppings, or oily films.

-

Key Insight for Asset Owners: Relying on rain alone leads to a gradual decline in energy production. A scheduled, professional cleaning is the only way to restore panels to their full potential.

- What Are the Key Safety Protocols for Cleaning?

- Safety is non-negotiable, particularly on rooftops. Adhere to these critical safety rules.

- De-energize the System: Always shut down the AC and DC disconnects before starting.

- Use Proper Fall Protection: Comply with OSHA requirements for fall protection, including harnesses and anchor points. Never work on a wet or icy roof.

- Avoid Abrasives and High Pressure: Never use stiff brushes, harsh chemicals, or high-pressure washers. These can damage the panel's anti-reflective coating or force water past seals, voiding the manufacturer's warranty.

- When Do Automated Systems Become Cost-Effective?

- The investment in robotic or semi-automated systems becomes financially viable when the long-term costs of manual labor and water exceed the TCO of the automated system. This tipping point typically occurs on projects larger than 1-2 MW, especially in areas with high labor costs or water restrictions. For a 5 MW solar farm, a robotic system can often achieve payback in 18 to 36 months through reduced operational expenses.

- At Portlandia Electric Supply, we deliver complete solutions tailored to your project. From a manual cleaning kit to a fully robotic fleet, our team is here to help you procure the right gear to protect your investment.

- Request a Quote to Streamline Your Next Project