How to Prevent Electrical Fires: A Field Guide for Installers, Facility Managers, and Property Owners

Share

To prevent electrical fires, you must address the root cause, not just the symptoms. It’s about specifying materials rated for the job, executing routine, documented system inspections, and ensuring every installation meets current NEC standards. This guide provides actionable frameworks for installers, facility managers, and property owners to mitigate the arc faults, overloaded circuits, and system degradation that lead to catastrophic failures. For professionals, this is about safety, compliance, and liability management. For owners, it's about protecting your assets.

Understanding the Real Sources of Electrical Fires

Electrical fires are rarely random events. They are the predictable outcome of specific system failures—identifiable issues that were either missed during installation or ignored during operation. Understanding these root causes is the only effective path to prevention.

According to the National Fire Protection Association (NFPA), U.S. fire departments responded to an estimated average of 46,700 home structure fires involving electrical failure or malfunction each year between 2015-2019. These incidents resulted in 420 civilian deaths, 1,410 civilian injuries, and $1.5 billion in direct property damage.

To mitigate this risk, you must master the fundamental principles of electrical safety and diagnose the specific failure points.

The Three Main Culprits

The common causes of electrical fires almost always trace back to one of these three failure modes:

- Arc Faults: An arc fault is an unintended, high-power discharge of electricity between conductors, generating temperatures exceeding 10,000°F that can instantly ignite adjacent materials.

- For Installers: This is a direct result of installation error—a staple driven through sheathing (violating NEC 300.4), a loose terminal screw, or damaged wiring insulation.

- For Facility Managers: This represents a hidden danger in aging systems or areas with high vibration, where connections can loosen over time.

- Overloaded Circuits: This occurs when more current is drawn through a circuit than it is rated to handle, causing dangerous overheating of the wiring.

- For Homeowners: This is often caused by plugging too many high-power devices (like space heaters or kitchen appliances) into a single circuit. A frequently tripping breaker is a critical warning, not an inconvenience.

- For Developers: Proper load calculation during the design phase is non-negotiable to prevent building-wide overload issues as occupant needs evolve.

- Deteriorating or Outdated Wiring: Legacy systems (e.g., knob-and-tube or 1960s-era aluminum wiring) were not designed for modern electrical loads. Over time, insulation becomes brittle and cracks, creating a significant fire hazard.

Critical Mistake: Viewing a frequently tripping breaker or flickering lights as a minor nuisance is a critical error. These are clear indicators of systemic issues like an overloaded circuit or a developing arc fault. For professionals, ignoring these signs is a direct path to liability. The job is to diagnose the root cause, not just reset the breaker.

Your First Line of Defense: Proactive Inspections

The most effective fire prevention strategy is proactive, systematic inspection. Waiting for the smell of burning plastic is a reactive failure. The goal is to identify the loose connection, frayed wire, or overloaded panel before it becomes a thermal event.

The effectiveness of this approach is well-documented. Japan's mandate for electrical installation inspections every four years, initiated in the 1960s, led to a 90% reduction in fires caused by electrical faults.

Tailoring the Inspection by Role

An effective inspection is tailored to the observer's expertise. A homeowner's role is to spot obvious surface-level hazards, while a professional's responsibility is to verify deep system integrity and code compliance.

Electrical Safety Inspection Checklist

| Area of Inspection | What Homeowners Should Look For | What Professionals Should Verify (NEC Focus) |

|---|---|---|

| Outlets & Switches | Discoloration, cracks, warm to the touch, buzzing/sizzling sounds. | Proper receptacle tension, correct wiring (no backstabbing), AFCI/GFCI functionality testing per manufacturer specs. |

| Cords & Plugs | Frayed, cracked, or damaged cords. Cords running under rugs. Overloaded power strips. | Appropriate cord gauge for the load, strain relief on connections, proper NEMA plug/receptacle types. |

| Electrical Panel | Odd smells (fishy/acrid), accessibility (not blocked), clearly labeled circuits. | Signs of overheating on breakers/bus bars (thermal imaging), proper breaker sizing (NEC 240.4), secure panel cover. |

| General Wiring | Exposed wires, damaged conduit. | Securely fastened cables (NEC 334.30), proper junction box fill and covers (NEC 314.16), no signs of rodent damage. |

A Walkthrough for Homeowners & Property Managers

Your goal is to identify clear warning signs without compromising safety. Perform this visual check quarterly.

- Look and Feel: Check outlets and switch plates. Discoloration, cracking, or warmth are indicators of a dangerous wiring issue behind the wall.

- Listen Closely: Buzzing, sizzling, or popping sounds from outlets often indicate an active arc fault.

- Trust Your Nose: A persistent fishy or acrid smell often points to overheating plastic from wiring insulation or device components.

- Check Cords: Inspect every appliance and extension cord. Replace anything frayed, cracked, or damaged. Never run cords under rugs, where damage can go unseen.

Checks for Facility Managers and Building Professionals

For those managing commercial or multi-family properties, a rigorous, documented approach is required for compliance and liability.

- Scheduled Audits: Implement and document quarterly visual inspections of all electrical rooms, panels, and high-load equipment areas.

- Panel Health & Thermal Imaging: During annual inspections, use a thermal camera to identify hotspots on breakers and bus bars that are invisible to the naked eye. Ensure all panels are clearly and accurately labeled and remain fully accessible (NEC 110.26).

- Documentation is Key: Maintain a detailed log of all inspections, findings, and corrective actions. This record is critical for safety compliance, insurance purposes, and liability management.

Pro Tip for Installers and EPCs: When on any service call, add a two-minute thermal scan of the main electrical panel as a value-added service. This simple step can identify high-resistance connections and failing breakers—critical fire risks—and immediately positions you as a proactive safety partner. It also generates qualified leads for necessary upgrades.

Remember, specialized systems like solar arrays require dedicated maintenance schedules. A comprehensive solar panel maintenance checklist is an essential tool for ensuring system safety and performance.

Choosing the Right Materials and Safety Devices

After a thorough inspection, remediation requires specifying and installing the correct materials. The components and safety devices you choose are a direct investment in fire prevention. Sourcing cheap, non-compliant parts is the fastest route to catastrophic failure and immense liability.

For any contractor or procurement manager, specifying UL-listed components and correctly gauged wiring is non-negotiable. It ensures compliance with the National Electrical Code (NEC), protects project timelines, and delivers a safe, reliable system.

This is a global issue. In England, electrical faults caused over 5,800 house fires in 2022/23, accounting for roughly 25% of all accidental dwelling fires. Faulty wiring and non-compliant appliances are consistently top culprits.

Modern Circuit Protection: AFCIs and GFCIs

Standard circuit breakers are effective against overloads and short circuits but are blind to the low-level arcing that ignites many electrical fires. Arc-Fault and Ground-Fault Circuit Interrupters (AFCIs and GFCIs) are specialized devices that address these hidden risks.

- Arc-Fault Circuit Interrupters (AFCIs): Required by the NEC in most dwelling unit living areas, AFCIs are specifically designed to detect the unique electrical signatures of dangerous arcs—the kind caused by damaged in-wall wiring or loose connections. The device de-energizes the circuit before the arc's intense heat can start a fire.

- Ground-Fault Circuit Interrupters (GFCIs): While known for shock prevention, GFCIs also play a role in fire safety. A GFCI monitors for current imbalances, such as electricity taking an unintended path to ground. By shutting off power in milliseconds, it prevents both electrocution and a potential ignition source in wet or damp locations.

Comparison of Essential Electrical Safety Devices

| Safety Device | Primary Function | Detects & Prevents | Common NEC Required Locations |

|---|---|---|---|

| AFCI | Fire Prevention | Unintended electrical arcs from damaged or loose wiring. | Bedrooms, living rooms, kitchens, laundry rooms, and other living areas in dwelling units. |

| GFCI | Shock Prevention | Unbalanced current flow (ground faults) when electricity takes an unintended path. | Bathrooms, kitchens (countertops), garages, outdoor receptacles, and any area near water. |

A similar device, the Residual Current Device (RCD), offers protection comparable to a GFCI and is a standard requirement in many international codes.

Upgrading Legacy Systems for Modern Safety

When evaluating an older property, a component-level fix is insufficient. The entire system must be assessed against modern safety standards.

Decision-Making Framework for Upgrades: The critical question is not "Is the panel working?" but "Does it meet current NEC safety codes?" This mindset shifts the focus to proactive safety. Prioritize replacing outdated panels (e.g., Federal Pacific, Zinsco), installing AFCI/GFCI protection as required by the current NEC, and verifying that wiring can handle modern electrical loads. This is not an upsell; it is a fundamental safety and compliance requirement.

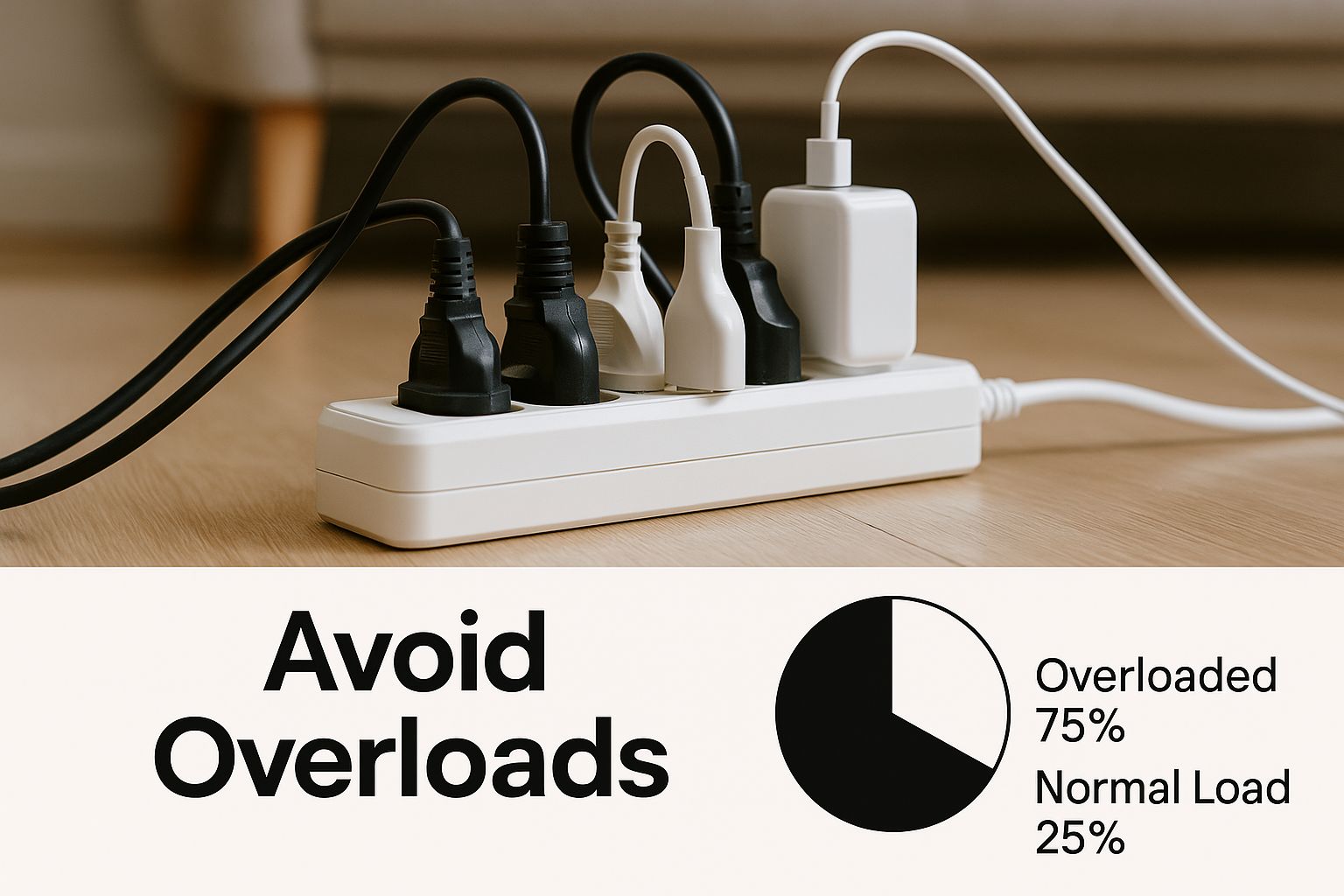

The image below illustrates one of the most common and preventable hazards: overloaded power strips.

This demonstrates that even properly installed systems can be compromised by improper use. As buildings adopt more complex loads, solutions like an https://www.portlandiaelectric.supply/products/what-is-a-energy-storage-system can help manage demand and enhance overall system safety.

Safe Installation and Proper Load Management

Superior materials are rendered useless by improper installation. Adherence to code, meticulous connections, and accurate load management are where fire prevention theory becomes reality.

For professional installers, the work must be fully compliant with the latest National Electrical Code (NEC). Shortcuts like overfilling junction boxes or failing to torque connections create latent hazards that can lead to failure years later.

Grounding and Secure Connections

Solid electrical connections are non-negotiable. A loose terminal screw or a poorly crimped connector creates resistance, which generates heat—the primary ingredient for an electrical fire.

- Torque Specifications: Use a calibrated torque wrench or screwdriver on all panel lugs and breaker terminals per manufacturer specifications and NEC 110.14(D). "Hand-tight" is not a recognized standard and is a common cause of high-resistance, hazardous connections.

- Secure Fastening: Wires within enclosures must be neatly organized and secured to prevent strain on terminals and avoid loosening from vibration over time.

-

Grounding Integrity: A continuous and robust equipment grounding conductor path is critical. It provides a safe path for fault current, allowing the circuit breaker to trip and preventing metal components from becoming energized.

A clean, organized panel is a direct indicator of a safe, professional installation. Properly torqued connections, neatly routed conductors, and clear, accurate labeling not only enhance safety but also simplify future maintenance and troubleshooting.

Calculating and Balancing Electrical Loads

Overloading a circuit is a fundamental and dangerous error. Every circuit has a maximum amperage rating; exceeding it causes conductors to overheat, degrading insulation and creating a fire risk.

Proper load management starts in the design phase. It requires a detailed calculation of all connected loads to ensure the total demand does not exceed the circuit's capacity.

- A standard 15-amp, 120-volt circuit is rated for 1,800 watts.

- A 20-amp, 120-volt circuit is rated for 2,400 watts.

For continuous loads, NEC requires that the load not exceed 80% of the circuit's rating.

- Map all loads: Identify every receptacle, light fixture, and appliance on each circuit.

- Calculate total wattage: Sum the wattage of all devices expected to operate simultaneously.

- Maintain a safety buffer: Ensure the calculated load is well under the circuit's maximum rating (ideally no more than 80%).

For projects involving significant new loads, like a backup generator, accurate calculations are paramount. Our detailed guide on how to size a whole house standby generator provides the necessary framework to ensure your system is safely and adequately provisioned from the start.

Best Practices for Appliance and Cord Safety

The point of connection—the appliance cord and plug—is a frequent point of failure. Proper cord and appliance safety is a practical, high-impact measure for fire prevention applicable to all users, from facility managers to homeowners.

Visual Cord and Plug Inspection

A power cord’s physical condition is a direct indicator of its safety. Frayed insulation, cracked sheathing, or exposed wires are immediate fire hazards.

- Inspect for Damage: Before each use, visually inspect the entire cord, paying close attention to the plug and the point of entry into the appliance, where stress is highest.

- Ensure a Secure Fit: A plug should fit snugly into a receptacle. A loose connection can arc and generate significant heat.

-

The Grounding Pin is Non-Negotiable: The third (round) prong is the equipment grounding pin. Never remove it to fit a two-prong outlet. Doing so defeats a critical safety feature designed to prevent shock and fire.

Pro Tip for Facility Managers: Implement a quarterly "cord audit" policy. Provide staff with a simple checklist to inspect their desk equipment (chargers, lamps, power strips). This empowers employees to identify common hazards before they escalate.

Preventing Overload of Outlets and Power Strips

The misuse of extension cords and power strips is a leading and preventable cause of electrical fires.

The practice of "daisy-chaining" (plugging one power strip into another) is a major fire code violation in commercial settings because it dramatically overloads the original wall receptacle and wiring.

Apply this same logic to high-draw appliances:

- Space Heaters & High-Wattage Appliances: Devices like portable heaters, microwaves, toasters, and air fryers draw significant current and must be plugged directly into a dedicated wall outlet. Using a standard extension cord or power strip with these appliances will cause overheating.

- EV Chargers: Electric vehicle charging requires a dedicated, professionally installed circuit sized for the specific EVSE (Electric Vehicle Supply Equipment). Using a standard extension cord is an extreme fire hazard and violates all safety codes.

Answering Your Top Electrical Fire Prevention Questions

What Are the Telltale Signs of an Electrical Fire Hazard?

Your electrical system will almost always provide warning signs before a catastrophic failure. Be vigilant for these red flags:

- Frequently Tripping Breakers: This indicates a persistent overload or a fault condition on the circuit.

- A "Fishy" or Acrid Burning Smell: This odor is often caused by overheating plastic components or wire insulation.

- Warm or Discolored Outlets/Switches: This signifies a high-resistance connection behind the wall plate, generating dangerous heat.

- Flickering or Dimming Lights: This often points to a loose connection somewhere in the circuit, which can lead to hazardous arcing.

If you observe any of these signs, contact a qualified electrician immediately.

Can I Use an Extension Cord as a Permanent Solution?

No. Extension cords are rated for temporary use only. They are not a safe or code-compliant substitute for permanent wiring.

Permanent use creates multiple risks: they are not designed for continuous load, are susceptible to physical damage, and encourage circuit overloading. If you require a permanent receptacle, the only safe solution is to have one professionally installed.

Expert Takeaway: Treat an extension cord like a spare tire. It's a temporary fix to get you out of a jam, but it's not safe for long-term, continuous use.

How Often Does My Electrical System Need an Inspection?

Inspection frequency depends on the property's age, condition, and use.

- For Homeowners: A professional inspection is recommended every 5-10 years. For homes over 20 years old or upon purchase, an immediate, thorough inspection is critical.

- For Commercial Buildings: Annual inspections by a qualified electrician are the industry standard for safety, compliance, and insurance purposes. Maintain all documentation.

Are AFCI Breakers Really That Important?

Yes, they are a non-negotiable component of modern electrical safety. Arc-Fault Circuit Interrupters (AFCIs) are mandated by the NEC in most living areas because they detect hazardous electrical arcs that standard breakers cannot. As building loads become more complex with the addition of sensitive electronics and energy storage systems—prompting questions like what is an energy storage system (https://www.portlandiaelectric.supply/products/what-is-a-energy-storage-system)—AFCI protection is more critical than ever. It is a primary defense against fires originating from hidden, damaged wiring.

At Portlandia Electric Supply, we provide contractors, developers, and facility managers with the high-quality, code-compliant materials required to build safe, reliable electrical systems. From AFCI breakers to correctly sized conductors, we are your partner in preventing electrical fires from the design phase through project completion.

Request a Quote today to ensure your project is outfitted with components that meet the highest standards of safety and performance.