How to Wire a 240V Outlet Safely and Correctly: A Guide for Installers & Homeowners

Share

Wiring a 240V outlet is a critical task for installing high-draw appliances like EV chargers, electric dryers, and ranges. This guide provides a step-by-step, code-compliant process for professional installers and advanced homeowners to ensure a safe and reliable installation. Following these instructions will help you pass inspections, prevent catastrophic failures, and power modern equipment correctly.

Understanding the Fundamentals of 240V Wiring

Before touching a wire, it's crucial to understand the core differences between 120V and 240V circuits. A 240V circuit isn't a simple upgrade; it's a dedicated, high-power line engineered for appliances that would instantly trip a standard breaker—think EV chargers, clothes dryers, water heaters, and electric stoves.

The key difference lies in the main electrical panel. A standard 120V circuit draws power from a single hot bus bar via a single-pole breaker. In contrast, a 240V circuit uses a robust double-pole breaker that connects to both hot bus bars simultaneously.

This dual connection doubles the voltage from 120V to 240V, delivering the power required by large appliances. Consequently, the entire circuit—breaker, wire gauge, and the outlet itself—must be specified to handle the higher load and comply with the National Electrical Code (NEC).

Why Different Appliances Need Different Outlets

Not all 240V outlets are interchangeable. The appliance's plug dictates the specific outlet required, based on its amperage rating and whether it has internal 120V components. The National Electrical Manufacturers Association (NEMA) standardizes these configurations to prevent mismatched connections.

For example, a modern electric dryer pulling 24 amps (5.7 kW) typically uses a NEMA 14-30 receptacle. However, a heavy-duty welder needing 40 amps (9.6 kW) requires a NEMA 6-50. You can discover more about how residential and industrial outlets differ, but the core principle is matching the outlet to the appliance's specific power requirements.

Pro Tip for Installers: Always verify the appliance's nameplate or manual before sourcing materials. This label specifies the exact amperage (e.g., 30A, 50A) and NEMA plug type. Guessing is the fastest way to fail an inspection or create a significant fire hazard.

Decoding NEMA Outlet Configurations

The NEMA numbering system on outlets provides all the necessary technical details. The primary distinction for 240V circuits is between 3-wire and 4-wire configurations. Understanding these is essential for project planning and code compliance.

| NEMA Type | Amperage | Common Application | Wires Required (inc. Ground) |

|---|---|---|---|

| NEMA 6-30 | 30A | Air conditioners, welders | 3 (Hot, Hot, Ground) |

| NEMA 6-50 | 50A | Welders, plasma cutters, large compressors | 3 (Hot, Hot, Ground) |

| NEMA 10-30 | 30A | Older electric dryers (pre-1996) | 3 (Hot, Hot, Neutral - No Ground) |

| NEMA 14-30 | 30A | Modern electric dryers | 4 (Hot, Hot, Neutral, Ground) |

| NEMA 14-50 | 50A | Electric ranges, EV chargers | 4 (Hot, Hot, Neutral, Ground) |

- 3-Wire Outlets (e.g., NEMA 6-50, 10-30): Common for equipment that runs exclusively on 240V (like a welder) or for older appliance circuits installed before modern code updates. The NEMA 10 series is now considered unsafe as it lacks a dedicated equipment ground.

- 4-Wire Outlets (e.g., NEMA 14-30, 14-50): As of the 1996 NEC, all new installations for appliances like dryers and ranges mandate a 4-wire circuit. This includes two hot wires, a ground, and a separate neutral wire. The neutral is a critical safety feature, providing a dedicated return path for any 120V components in the appliance, such as timers, lights, and control boards.

Gathering the Right Tools and Materials

A successful 240V installation is determined by meticulous preparation. Having the correct, high-quality tools and NEC-compliant materials ready is non-negotiable for safety and efficiency. This is a professional-level task requiring specialized tools designed for heavy-gauge wire and circuit verification.

The Essential Tool Kit

- Non-Contact Voltage Tester: Your primary safety tool. Use it to confirm the circuit is de-energized before any physical contact. Never trust a breaker label alone.

- Multimeter: Used for final verification. It confirms correct voltage readings: 120V from each hot to neutral/ground and 240V across the two hot conductors.

- Heavy-Duty Wire Strippers: Must be rated for 10-gauge or 8-gauge NM-B cable to ensure clean strips without nicking the copper.

- Lineman's Pliers: Essential for cutting heavy-gauge cable and twisting copper conductors.

- Screwdrivers: A quality multi-bit driver with flathead, Phillips, and square-drive tips for terminal and breaker lugs.

- Fish Tape: Indispensable for pulling new cable through finished walls and conduit runs from the panel to the outlet location.

Sourcing the Right Materials

Material selection is dictated by the appliance's load and is a critical safety requirement. Using undersized wire is a major fire hazard due to overheating under load.

For Procurement & Installers: Never substitute materials to reduce costs. The wrong breaker size or wire gauge will result in a failed inspection, requiring a costly and time-consuming rework. Base your Bill of Materials on the appliance's specified amperage rating.

Procurement Checklist: 30-Amp Dryer Circuit

- Double-Pole Circuit Breaker: A 30-amp breaker that occupies two adjacent slots. It must be the same brand as your panel (e.g., Square D, Eaton, Siemens) to comply with UL listings.

- Electrical Cable: 10/3 NM-B copper wire. The "10" denotes the gauge, and the "3" indicates three insulated conductors (black, red, white) plus a bare copper ground.

- 240V Receptacle: A NEMA 14-30R outlet, matching the appliance plug.

- Electrical Box: A deep "new work" or "old work" box to accommodate the bulk of 10/3 wire without crowding.

- Cable Clamp: Secures the NM-B cable at the box entry point to protect it from physical damage.

If running wire through exposed areas like an unfinished basement or garage, it requires protection. Our guide on how to install electrical conduit provides step-by-step instructions for ensuring a code-compliant and protected installation.

Preparing the Circuit Path and Breaker Panel

With materials sourced, the next phase involves site preparation. Careful planning of the cable route and meticulous safety procedures at the breaker panel are essential to avoid project delays and hazards.

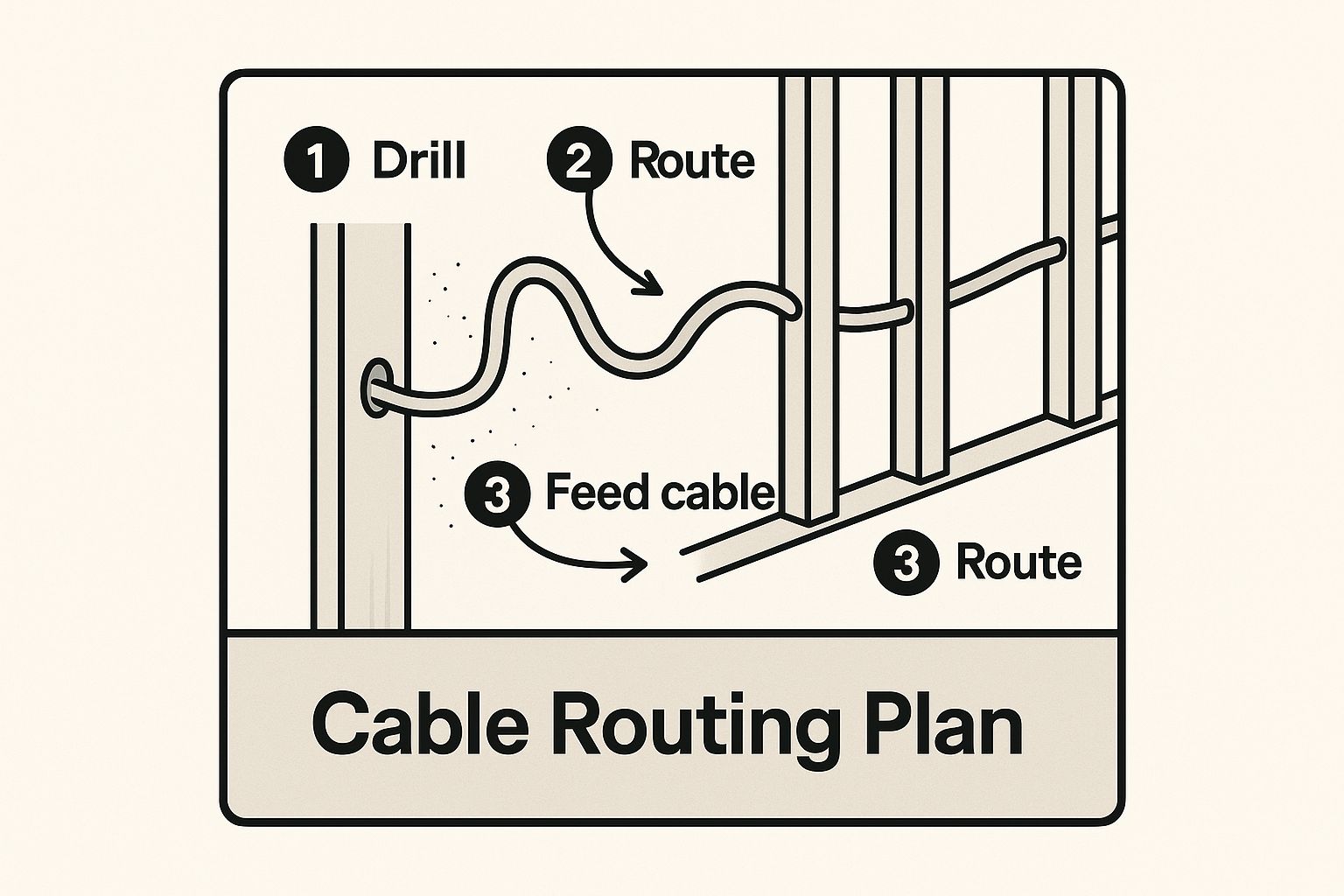

Before drilling, map a clear path from the panel to the outlet location, accounting for wall studs, ceiling joists, and fire blocks. This foresight minimizes drywall damage and simplifies the cable pull.

Drilling through the center of studs, as shown, protects the wire from future damage by drywall screws.

De-Energizing the Panel for Maximum Safety

This is the most critical safety step. Working in a live electrical panel can be fatal. Follow this procedure exactly.

Shut off all power by flipping the main breaker (typically 100A or 200A) to the "OFF" position. This de-energizes the entire home.

Critical Safety Protocol: After flipping the main breaker, use your non-contact voltage tester to verify that power is off. Carefully check the main lugs where utility lines enter the panel, then test several individual circuit breakers. Do not proceed until you are 100% certain the panel is dead.

Running and Securing the New Cable

With the panel confirmed de-energized, begin running the new cable. Start at the outlet box and fish the wire back toward the panel, leaving approximately 18-24 inches of slack at both ends to facilitate connections.

Properly securing the cable is an NEC requirement that prevents damage and future hazards.

NEC Cable Securing Requirements:

- Secure the wire with a cable staple within 12 inches of any non-metallic electrical box.

- Along the run, staple the cable to studs or joists at least every 4.5 feet.

- When drilling through studs, maintain a centered position.

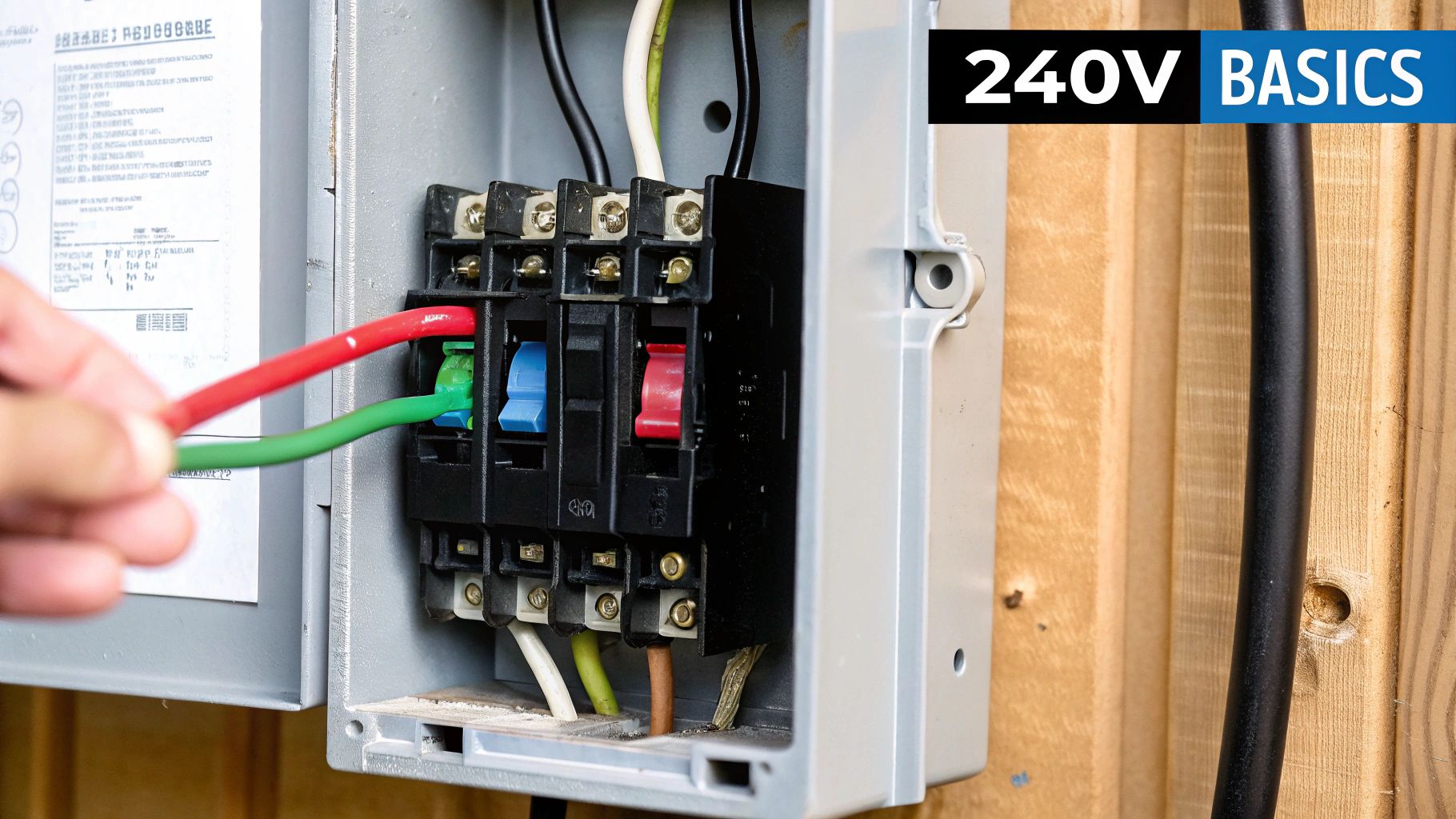

Preparing the Breaker Panel for the New Circuit

At the panel, remove a knockout plug for the new cable entry. Install a cable clamp in the opening and tighten its locknut securely.

Feed the new cable through the clamp into the panel, leaving enough slack to reach the bus bars and the new breaker. Tighten the clamp's screws just enough to hold the cable firmly without damaging the outer sheathing.

Next, install the new double-pole breaker. Locate two empty, adjacent slots. Align the breaker and press it firmly into place until it seats onto the hot bus bars with a distinct "snap."

Selecting the correct breaker is fundamental. For detailed guidance, consult our resource on how to size circuit breakers to ensure you make the right choice for your specific load.

Making the Connections at the Outlet and Panel

With the cable run and power confirmed off, precision becomes paramount. Loose connections are a primary cause of electrical failures and fires. This process is divided into two stages: wiring the receptacle, then terminating the circuit at the breaker panel.

Wiring the 240V Receptacle

At the outlet box, carefully strip the outer vinyl sheathing from the NM-B cable, exposing about 6 to 8 inches of the inner wires. This provides adequate slack for making secure connections.

Using your wire strippers, remove approximately 3/4 of an inch of insulation from the ends of the black, red, and white conductors. The bare copper ground wire requires no stripping.

Examine the back of the NEMA 14-30R (or similar 4-wire) receptacle. The terminal screws are color-coded for specific connections.

- Hot Wires: The two brass-colored screws are for the "hot" legs. Connect the black wire to one and the red wire to the other. The order does not matter.

- Neutral Wire: The silver-colored screw is for the neutral conductor. Connect the white wire here.

- Ground Wire: The green screw is exclusively for the ground. Connect the bare copper wire here.

Bend a small hook at the end of each stripped wire using pliers. Wrap the hook clockwise around the screw shaft; this ensures that tightening the screw also tightens the wire loop, creating a secure mechanical and electrical connection.

Pro Tip for Installers: After tightening each terminal, give the wire a firm tug. Any movement indicates an insecure connection that must be re-tightened. This simple physical check is essential for a safe, professional installation.

For a 3-wire outlet (e.g., NEMA 6-50), connect the two hots (black and red) to the brass screws and the bare copper ground to the green screw. There is no neutral wire or silver screw in this configuration.

Installing the Breaker and Connecting at the Panel

Return to the main panel. With the new double-pole breaker already snapped into two open slots, you are ready to terminate the circuit.

For a 4-Wire Circuit (NEMA 14-30 or 14-50):

- Connect the black wire to one of the screw terminals on the new breaker.

- Connect the red wire to the other screw terminal on the breaker.

- Land the white neutral wire on an open terminal on the neutral bus bar (the silver bar with other white wires).

- Land the bare copper ground wire on an open terminal on the ground bus bar (typically bonded to the panel enclosure).

For a 3-Wire Circuit (NEMA 6-30 or 6-50):

- Connect the black and red wires to the two breaker terminals.

- Connect the bare copper ground to the ground bus bar.

- The neutral bus bar is not used for this circuit.

Perform a final check on all connections for tightness. Organize the new wiring neatly inside the panel, then replace the panel cover, ensuring no wires are pinched.

Finalizing the Install and Performing Safety Checks

The physical installation is complete, but the job is not finished. The final steps—careful assembly and systematic voltage verification—are what separate a safe, professional installation from a dangerous hazard.

Gently fold the wires into the electrical box using accordion-like folds to avoid straining the terminal connections. Secure the outlet to the box with its mounting screws, ensuring it sits flush and level. Attach the cover plate.

The Non-Negotiable Voltage Verification

This is the moment of truth. At the panel, perform a final visual sweep for tools or debris, then reinstall the cover. Restore power by flipping the main breaker to "ON," followed by the new double-pole breaker.

Return to the outlet with your multimeter. This test is the only way to be 100% certain the outlet is wired correctly and is safe to use.

Safety Mandate: Never skip the multimeter test. Assuming a correct installation without verification is a rookie mistake that can destroy expensive appliances and poses a severe safety risk. This check protects the equipment, the property, and lives.

Reading the Multimeter

Set your multimeter to measure AC voltage (V~). For a 4-wire circuit (NEMA 14-30 or 14-50), you must obtain the following specific readings. Any deviation requires immediate de-energization and troubleshooting.

- Hot to Neutral: Place one probe in a hot slot and the other in the neutral slot. The reading should be ~120V.

- Other Hot to Neutral: Test the second hot slot against the neutral. The reading should again be ~120V.

- Hot to Ground: Test each hot slot against the round ground pin. Both should read ~120V.

- Hot to Hot: Place one probe in each of the two hot slots. The meter must read ~240V.

If any readings are incorrect, turn off the breaker immediately and re-inspect your wiring at both the outlet and the panel. Proper voltage is the foundation of a safe circuit. Knowing how to prevent electrical fires begins with disciplined verification.

With the proliferation of electric vehicles, the average professional cost for a 240V outlet installation is approximately $220, with a typical range of $175 to $300 depending on project complexity.

Once you have confirmed all voltage readings are correct, the installation is complete. Your new high-power outlet is safe and ready for service.

Got Questions? Let's Clear Things Up.

Even with a detailed guide, unique site conditions can raise questions. For 240V wiring, asking questions is a sign of a safety-conscious installer.

Here are answers to common queries.

Can I Just Convert a 120V Outlet to 240V?

No. A standard 120V circuit uses a single-pole breaker and smaller gauge wiring (typically 14/2 or 12/2) incapable of handling the amperage of a 240V appliance. Attempting to convert it is a serious fire hazard and a major code violation. A new, dedicated circuit must be run from a new double-pole breaker using appropriately sized wire (e.g., 10/3 or 6/3).

What's the Real Difference: 3-Wire vs. 4-Wire 240V Outlets?

The key difference is the dedicated neutral wire. A 3-wire setup includes two hots and a ground. A modern 4-wire circuit adds a separate neutral conductor.

Code is King: Since the 1996 NEC, 4-wire outlets (e.g., NEMA 14-30, 14-50) are mandatory for new dryer and range installations. This is a safety requirement. The separate neutral provides a safe return path for 120V components within the appliance (timers, control boards, lights), preventing dangerous current from traveling on the equipment ground wire.

The shift to higher voltage for heavy-duty appliances is a global trend. While the US uses 120V as a standard, many regions in Europe and Asia use 230-240V as their primary voltage. You can discover more insights about global outlet standards on kristechwire.com.

How Do I Pick the Right Breaker and Wire Size?

The appliance's nameplate or manual specifies the required amperage. This rating dictates the correct breaker and wire size.

- 30-Amp Appliance: Requires a 30-amp double-pole breaker and 10-gauge copper wire (10/3 NM-B for 4-wire).

- 50-Amp Appliance: Requires a 50-amp double-pole breaker and 6-gauge copper wire (6/3 NM-B for 4-wire).

Always match components to the appliance's load rating to prevent overheating and hazards.

When Should I Put the Tools Down and Call a Pro?

While DIY is commendable, safety is paramount. It is time to call a licensed electrician if:

- You are uncertain about any step in this process.

- Your electrical panel lacks the physical space for a new double-pole breaker.

- You encounter old aluminum wiring.

- Your local jurisdiction requires a permit and inspection for this type of work.

A professional ensures the job is done correctly, safely, and to code, providing peace of mind and protecting your investment.

From Tier 1 solar modules to the specific breakers and gear for your next electrical job, Portlandia Electric Supply is your full-service partner. We offer NABCEP-certified design review and make sure you get the exact, code-compliant materials you need, delivered fast. Request a Bulk Quote or get in touch with an expert today to get your project started right.