HVAC Duct Sizing Chart for Accurate Airflow Calculations

An HVAC duct sizing chart is an essential tool for installers, EPCs, and project managers to translate system airflow requirements, measured in cubic feet per minute (CFM), into specific duct dimensions. The primary goal is to maintain an optimal friction loss rate—typically 0.1 inches of water column—to ensure the HVAC system operates efficiently, quietly, and delivers balanced comfort.

Getting duct sizes right from the design phase is critical for project success. This guide provides the charts, step-by-step instructions, and expert tips to prevent common field mistakes, ensuring your installations meet performance specs and avoid costly callbacks.

The Essential HVAC Duct Sizing Chart For Field Use

For HVAC professionals—installers, engineers, and procurement managers—a reliable duct sizing chart is a non-negotiable tool. It bridges the gap between calculated airflow needs and the physical ductwork required on-site. Even minor sizing errors can lead to significant performance issues, impacting efficiency, comfort, and operational costs.

Proper duct sizing directly influences three make-or-break project outcomes:

- System Efficiency: Undersized ducts increase static pressure, forcing the air handler to work harder and consume more energy to deliver the required airflow. This violates a core principle of efficient system design.

- Occupant Comfort: Oversized ducts result in low air velocity, causing poor circulation and inconsistent temperatures. Conversely, undersized ducts create noise and uncomfortable drafts.

- Operational Costs: Efficient airflow minimizes energy waste, directly reducing utility bills for the building owner. For contractors, it means fewer callbacks to troubleshoot performance complaints.

The data is clear: according to industry studies, undersized ductwork can increase fan energy consumption by 20-30% due to excessive static pressure. For a deeper technical review, you can discover more insights about HVAC duct systems on inspectapedia.com.

Quick Reference HVAC Duct Sizing Chart (0.1" Friction Loss)

Here is a straightforward duct sizing chart designed for quick lookups in the field. The values are based on the industry-standard friction loss rate of 0.1 inches of water column per 100 feet of duct. This is a common and reliable baseline for most residential and light commercial projects that use rigid metal ductwork.

| Airflow (CFM) | Recommended Round Duct Diameter (inches) | Common Rectangular Duct Dimensions (inches) |

|---|---|---|

| 50 | 4 | 3.25 x 10, 6 x 4 |

| 100 | 6 | 3.25 x 14, 8 x 6, 10 x 4 |

| 150 | 7 | 6 x 10, 8 x 8, 12 x 6 |

| 200 | 8 | 8 x 10, 10 x 8, 12 x 6 |

| 300 | 9 | 8 x 12, 10 x 10, 14 x 8 |

| 400 | 10 | 10 x 12, 12 x 10, 16 x 8 |

| 600 | 12 | 12 x 14, 16 x 10, 20 x 8 |

| 800 | 14 | 14 x 16, 18 x 12, 22 x 10 |

| 1000 | 16 | 16 x 18, 20 x 14, 24 x 12 |

| 1500 | 18 | 18 x 22, 22 x 18, 26 x 16 |

| 2000 | 20 | 20 x 24, 24 x 20, 28 x 18 |

Use this table to quickly find the right round or rectangular duct size for the CFM you've calculated. Starting with these dimensions helps ensure your project is built on a solid, efficient foundation right from the get-go.

Understanding Core Duct Sizing Principles

Anyone can look at a duct sizing chart, but understanding the engineering principles behind it is what separates professional installers from amateurs. Effective duct design is a balancing act between three interdependent factors. Mastering this balance is essential for achieving optimal performance, energy efficiency, and client satisfaction.

These principles form the basis of industry standards from organizations like the American Society of Heating, Refrigerating and Air-Conditioning Engineers (ASHRAE). They ensure that ductwork functions as an engineered component of a high-performance HVAC system.

Airflow Volume (CFM)

Airflow volume, measured in cubic feet per minute (CFM), is the amount of conditioned air required to heat or cool a space effectively. This value is determined by a formal load calculation, which considers factors like room size, insulation levels, window area, and occupancy. Every duct size on a chart corresponds to a specific CFM target. An inaccurate initial CFM calculation will lead to an improperly sized system, regardless of the chart's accuracy.

Air Velocity (FPM)

Air velocity, measured in feet per minute (FPM), is the speed at which air travels through the ductwork. This is a critical trade-off:

- Too slow: The air may not have enough force to reach distant registers, leading to poor air distribution.

- Too fast: High velocity causes unwanted noise (whooshing sounds) and increases static pressure, straining the system's fan.

For Installers: Target an air velocity between 600 and 900 FPM for residential supply ducts. Return ducts can be slightly lower. Commercial systems can tolerate higher velocities, but noise remains a key design constraint.

Friction Loss

Friction loss is the resistance, or pressure drop, that air encounters as it moves along the interior surfaces of the duct. It is measured in inches of water column (in. w.c.) per 100 feet of duct. Every component—elbows, transitions, dampers, and takeoffs—contributes to the total system friction.

Most duct sizing charts are standardized for a friction loss rate of 0.1". This is a reliable baseline for typical systems. However, for long, complex duct runs with numerous fittings, a more conservative rate may be necessary to ensure adequate airflow at the furthest outlets. Proper management of friction loss is one of the most effective ways to improve HVAC efficiency and lower energy bills.

These three principles—CFM, FPM, and friction loss—are interconnected. A change in one affects the others. A duct sizing chart is a tool that simplifies the complex calculations required to find the optimal balance between them.

A Practical, Step-by-Step Guide to Using a Duct Sizing Chart

In the field, translating engineering plans into a functional HVAC system requires precision. A duct sizing chart, or ductulator, is a fundamental tool for this process. This guide provides actionable steps for using a chart correctly on any residential or light commercial project.

This process eliminates guesswork. By starting with accurate airflow requirements and selecting an appropriate friction rate, you can determine the correct duct dimensions every time, ensuring the system performs as designed.

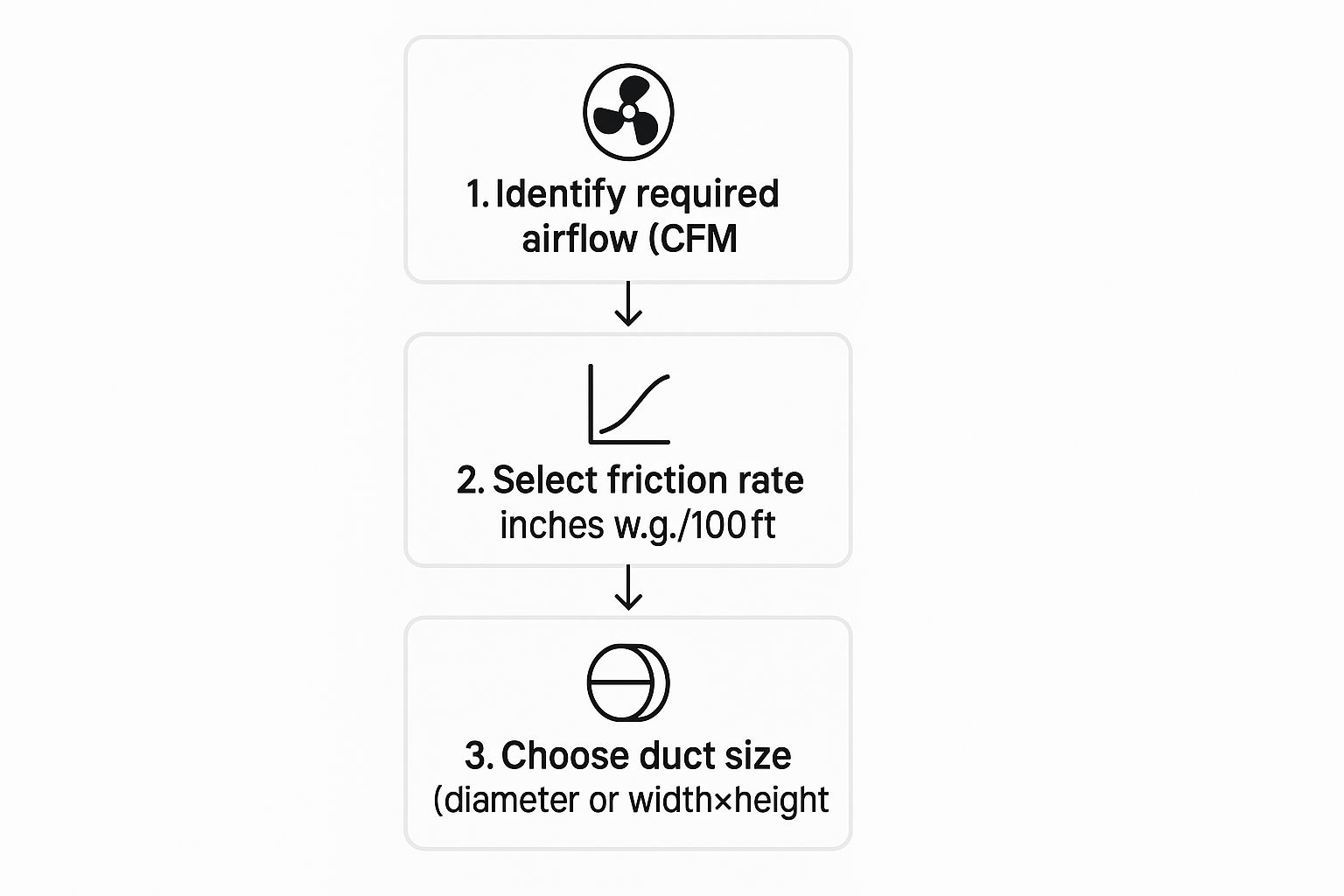

This image lays out the basic three-step process we're about to cover.

The process boils down to three key inputs: determining required CFM, selecting a friction loss rate, and using those values to identify the correct duct size.

Step 1: Figure Out the Required Airflow (CFM)

Before consulting a sizing chart, you must determine the required airflow for each room in Cubic Feet per Minute (CFM). This value must be derived from a professional load calculation, such as an ACCA Manual J analysis. This calculation accounts for all heat gains and losses based on room dimensions, insulation, window specifications, and occupancy.

For example, a small bedroom might only require 50-75 CFM, while a large, open-concept living area could demand 300 CFM or more. Each duct run must be sized for the specific CFM it is intended to deliver.

Step 2: Choose a Friction Loss Rate

Next, select a friction loss rate, measured in inches of water column per 100 feet of duct (in. w.c./100 ft). This rate represents the acceptable level of airflow resistance in the system.

For standard residential systems using rigid metal ductwork, 0.1" is the industry-standard starting point. However, this is not a one-size-fits-all value. For systems with long, complex runs, numerous fittings, or significant use of flexible duct, a lower friction rate (e.g., 0.08") may be more appropriate to compensate for the higher resistance.

Critical Mistake: Defaulting to the 0.1" rate without considering the total equivalent length (including fittings) is a common error. On a high-resistance system, this leads to under-delivery of air and poor performance. Always assess the layout first.

Step 3: Find the Duct Size on the Chart

With your CFM and friction rate determined, you can now use the chart:

- Locate your target CFM in the first column of the chart.

- Follow that row across to the column corresponding to your chosen friction loss rate (e.g., 0.1").

- The intersecting value provides the required duct size. The chart will typically show the diameter for round duct and equivalent dimensions for rectangular duct.

Following these three steps methodically will translate system requirements into accurate, real-world duct sizes that ensure proper performance.

Comparing Duct Sizing Methods and Tools

While an HVAC duct sizing chart is an essential field tool, professional engineers and system designers rely on established design methodologies. The choice of method impacts system performance, installation cost, and operational efficiency, particularly in complex commercial and industrial applications.

The evolution of duct sizing from empirical rules to standardized engineering practices, led by organizations like ASHRAE, has been crucial for creating predictable and efficient air distribution systems.

Core Sizing Methodologies

Three primary methods are used for duct design, each suited for different project requirements.

- Equal Friction Method: This is the most common method and the basis for most duct sizing charts. It maintains a constant friction loss rate (e.g., 0.1" w.c.) throughout the entire duct system. Its relative simplicity makes it ideal for straightforward, symmetrical layouts.

- Velocity Reduction Method: In this approach, the air velocity is systematically reduced after each branch or takeoff. It is often used in industrial applications where precise velocity control is a primary objective. This method requires more detailed calculations to maintain system balance.

- Static Regain Method: This is the most complex and accurate method, engineered to provide uniform static pressure at every outlet. It is the preferred method for long, intricate duct systems in large commercial buildings, where balanced airflow to every diffuser is non-negotiable.

Jobsite Tools: From Old School to Digital

The tools for applying these methods have evolved alongside the methodologies themselves.

For Installers: The choice between a ductulator and software is a trade-off between speed and comprehensive analysis. A slide rule is excellent for quick on-site verification, while software provides a complete system model that accounts for every fitting and pressure drop.

A traditional ductulator—the circular slide rule familiar to every HVAC technician—is a fast and effective tool for applying the Equal Friction method directly on the job site.

In contrast, digital software offers a much more powerful analysis. Programs from companies like Wrightsoft or Elite Software can model an entire duct system, calculating the total equivalent length from all fittings and applying any of the three main sizing methods. For designers, this level of detail is essential for optimizing complex systems and ensuring compliance. This detailed planning is just as vital as understanding the electrical demands of the equipment; for more on that, see our guide on converting kilowatt-hours to amps.

Critical Mistakes to Avoid in Duct Sizing

Possessing accurate charts and software is not enough. Even experienced professionals can make oversights during design and installation that lead to significant performance issues. Avoiding these common pitfalls is as important as the initial calculations.

These errors result in noisy, inefficient systems that fail to deliver conditioned air effectively. The consequences range from high energy bills and occupant discomfort to premature equipment failure, leading to costly callbacks and reputational damage.

Ignoring Fittings and Bends

A frequent and critical error is sizing duct runs based solely on their linear length while ignoring the resistance added by fittings. Every elbow, tee, transition, and damper contributes to the equivalent length of the run. A single sharp 90-degree elbow can add the same friction as 15-30 feet of straight duct. Neglecting these components will cause the system's actual static pressure to be much higher than calculated, severely restricting airflow.

Pro Tip for Installers: Perform a quick mental calculation of equivalent length for each run. If a duct path includes more than two or three sharp turns, consider increasing that duct section by one size. This simple adjustment helps compensate for the added friction and ensures you meet the target CFM.

Undersizing Return Air Ducts

Focusing exclusively on the supply side while neglecting the return duct is a catastrophic mistake. An undersized return duct starves the air handler, forcing the blower motor to work harder to draw in sufficient air. This strain increases energy consumption and can lead to severe equipment damage, such as a frozen evaporator coil in cooling mode or an overheated heat exchanger in heating mode. Identifying these system-wide issues is critical; learning how a comprehensive home energy audit can reveal inefficiencies can provide valuable context.

Failing to Adjust for Duct Material

Not all duct materials have the same airflow characteristics. A common error is using a sizing chart for smooth sheet metal and then installing flexible duct of the same diameter. The corrugated interior of flex duct creates significantly more turbulence and friction.

- Rigid Metal Duct: The smooth interior allows air to move with minimal resistance and low friction loss.

- Flexible Duct: The rough, ribbed lining dramatically increases friction. To achieve the same airflow as a rigid duct, you must often increase the diameter by one or even two sizes.

Using the same size for both will result in severely restricted airflow in the flexible sections, leading to an unbalanced and uncomfortable system. Always consult the manufacturer's engineering data for the specific flexible duct being installed to ensure accurate sizing.

Getting the Right Ductwork to the Job Site

An accurate HVAC duct sizing chart is useless without a reliable supply chain to deliver the specified materials to the job site on time. This is where meticulous design meets the logistical realities of procurement. A strategic supply partner is essential for keeping projects on schedule and within budget.

For contractors and procurement managers, sourcing the correct duct sizes and fittings under tight deadlines is a major challenge. Last-minute design changes and supply chain disruptions can derail even the best-laid plans. At Portlandia Electric Supply, our procurement and logistics are structured to mitigate these risks.

From Blueprint to Building Site

- We bridge the gap between your design specifications and the physical inventory you need on-site. We serve as a single-source supplier for the entire HVAC material package, simplifying your procurement process.

Maintain a deep inventory of common round and rectangular duct sizes, minimizing lead times for critical components. - Bundled Freight Options: Consolidate your ductwork with air handlers, condensing units, and controls into a single shipment. This saves significant time and reduces freight costs. One order, one delivery, one invoice.

-

Rapid Quoting: Submit your material list, and our team will provide a fast, comprehensive quote, allowing you to secure materials and move your project forward without delay.

For Procurement Managers: Material delays can increase project labor costs by 10-15% or more due to crew downtime. A reliable supply chain is not a luxury—it is a critical component of risk management and profitability.

By integrating your sizing calculations with our procurement process, you can lock in materials and maintain your project schedule. Ready to streamline your procurement? Request a bulk quote with your material list and let our team manage the logistics.

Common Duct Sizing Questions Answered

Even with reliable charts, specific questions inevitably arise during design or installation. Knowing the answers to these common queries can save time, prevent errors, and ensure a high-quality installation.

This section provides quick, expert answers to frequently asked questions from contractors and designers in the field.

What’s the Right Air Velocity for Residential Ducts?

Achieving the correct air velocity is a balance between effective air delivery and noise control.

For residential systems, the target velocity for supply ducts is between 600 and 900 Feet Per Minute (FPM). For return ducts, a slightly lower velocity of 500 to 700 FPM is ideal. Adhering to these ranges ensures sufficient airflow to distant rooms without creating the audible "whooshing" that leads to homeowner complaints and callbacks.

How Does Flex Duct Change the Sizing Game?

Treating flexible duct and rigid metal duct as interchangeable is a critical sizing error. The rough, corrugated interior of flex duct creates significantly more friction, which impedes airflow.

To compensate for this increased resistance, you must almost always size up by at least one diameter compared to what a chart for rigid duct indicates. For example, if your calculation calls for a 6-inch rigid duct, you should use a 7-inch or 8-inch flexible duct to deliver the same CFM without a major pressure drop.

Expert Tip for Installers: When installing flex duct, pull it taut. A straight, fully extended run has dramatically lower friction loss than a compressed or sagging run with sharp bends. A sloppy installation can easily double the friction, negating any benefits of proper sizing.

Can I Use the Same Sizing Chart for Heating and Cooling?

Yes. The principles of airflow dynamics do not depend on air temperature.

A duct sizing chart is based on airflow (CFM) and friction loss, which are independent of whether the air is hot or cold. The required CFM is determined by a load calculation, such as an ACCA Manual J, which calculates the airflow needed for both heating and cooling. You should always design the duct system to handle the greater of the two loads. Once the target CFM is established, the sizing process is identical for both applications.

At Portlandia Electric Supply, we help you turn those plans into reality. Once your duct sizes are locked in, our team can get you a fast quote on all the materials you need, with bundled freight to keep your project moving. For a complete material and logistics solution, check out your options at https://portlandiaelectric.supply.