A Guide to Electric Panel Bus Bar Selection, Sizing, and Compliance

This guide is for electrical installers, EPCs, developers, and procurement managers who specify, purchase, or install power distribution systems. It provides a real-world framework for selecting the right electric panel bus bar, ensuring it's sized for the application, and installed according to National Electrical Code (NEC) standards to avoid costly failures and ensure project safety. By the end, you will be equipped to make informed procurement and installation decisions that balance cost, performance, and long-term reliability.

The Backbone of Modern Power Distribution

For any professional in the field, the electric panel bus bar is the literal backbone of a power distribution system. It's a thick, conductive metal strip—typically copper or aluminum—that serves as the central hub inside a switchboard or panelboard, efficiently routing high currents from a single source to multiple circuits.

This isn't just another component. A decision on bus bar material, size, or ampacity rating directly impacts project risk, timelines, and total cost. Skimping on these details can lead to equipment failure, unplanned downtime, and significant safety hazards, including arc flash events. When specified and installed correctly, a bus bar system ensures power is distributed cleanly and safely, a non-negotiable requirement for high-load industrial, commercial, and utility-scale applications.

The market reflects this critical role. The global busbar market was valued at USD 19 billion in 2024 and is projected to hit USD 28.82 billion by 2034, according to this detailed market analysis. This growth is driven by the demand for more reliable, space-efficient, and faster-to-install electrical infrastructure.

Guidance by Professional Role

- For Installers & EPCs: A bus bar system dramatically reduces installation complexity and labor hours compared to traditional wiring. Fewer termination points mean faster commissioning and fewer potential points of failure, a critical advantage in complex projects like three-phase power systems.

- For Procurement Managers & Developers: While the upfront material cost of a bus bar system might seem higher than cable, the total installed cost is often lower. Factoring in reduced labor, faster project timelines, and smaller, less expensive enclosures reveals significant savings and a better ROI.

Critical Mistake to Avoid: Don't just compare line-item component costs in bids. A bus bar system's value is in its total installed cost and long-term reliability. Portlandia Electric Supply's rapid quoting and bundled logistics for bus bars and associated components can further optimize project budgets and timelines.

Bus Bar Systems vs. Traditional Cabling: A Project Snapshot

This table outlines the key operational and financial advantages of specifying an engineered bus bar system over a conventional cable and conduit approach for power distribution.

| Metric | Electric Panel Bus Bar System | Traditional Cable and Conduit |

|---|---|---|

| Installation Time | Faster: Prefabricated components and fewer connection points significantly reduce labor hours. | Slower: Requires cutting, stripping, and terminating numerous individual cables, a time-intensive process. |

| Space Efficiency | High: Compact design allows for smaller, denser panelboards and switchgear enclosures. | Low: Bulky cables and conduits require significantly more space and careful routing. |

| Total Project Cost | Often Lower: Reduced labor, smaller enclosures, and faster commissioning offset material costs. | Variable: Initial material cost may be lower, but labor and space requirements often drive up total costs. |

| System Reliability | Higher: Engineered connections and fewer termination points minimize potential failure and improve thermal performance. | Lower: Multiple terminations and splices increase the risk of loose connections and overheating over time. |

For modern electrical demands, bus bar systems provide a superior engineered solution that enhances efficiency, safety, and reliability from day one.

Choosing the Right Bus Bar Material and Type

Selecting the correct bus bar for an electrical panel is a foundational engineering decision that impacts cost, performance, and long-term system reliability. For engineers and procurement managers, the choice begins with the two primary materials: copper and aluminum.

Copper is the industry benchmark due to its superior electrical conductivity and mechanical strength. This allows for a smaller, more compact bus bar to handle the same current (ampacity) as a larger aluminum counterpart, making it the ideal choice for high-density panelboards and switchgear where space is at a premium.

Aluminum offers a significant cost advantage—often 30-50% cheaper than copper for an equivalent ampacity. Its lighter weight also reduces structural load requirements and simplifies handling for installers on large-scale projects. However, aluminum is more susceptible to oxidation, requiring diligent surface preparation to ensure a reliable, low-resistance connection that prevents overheating.

Matching Bus Bar Type to Application

After selecting a material, the next step is choosing the form factor. The bus bar's shape is engineered for specific applications, and understanding the differences between flat, solid, and laminated types is crucial for system designers.

- Flat Bus Bars: Simple, rectangular bars that are the most common and cost-effective solution for standard switchgear and panelboards.

- Solid Bus Bars: Thicker, more rigid bars (often square or cylindrical) used in high-voltage switchyards and heavy industrial applications where mechanical strength against short-circuit forces is critical.

-

Laminated Bus Bars: A high-performance assembly of thin conductive layers separated by dielectric insulation. This design minimizes stray inductance and electrical noise, making it essential for sensitive, high-frequency equipment like variable frequency drives (VFDs) and power inverters.

The rapid growth in the electric vehicle (EV) sector, where the EV busbar market surpassed USD 776 million in 2024, highlights this evolution. This demand is driven by the need for efficient, lightweight laminated busbars to manage high currents in compact spaces. You can review these trends in the electric vehicle busbar market report.

Pro Tip for Installers & EPCs: Pay close attention to bus bar plating. Standard tin plating prevents oxidation on both copper and aluminum. For corrosive or harsh environments, specifying silver or nickel plating is a smart investment. It improves conductivity and provides superior durability, preventing galvanic corrosion and ensuring the long-term integrity of critical connections. At Portlandia Electric Supply, we can source bus bars with custom plating to meet specific project demands.

Ultimately, the choice is a balance of cost, space, and performance. A standard aluminum bar may suffice for a commercial building, but a high-performance laminated bus bar is non-negotiable for a data center or EV charging station. Making the right decision upfront prevents costly rework and ensures the system operates safely and efficiently for its entire service life.

Ampacity Ratings and the NEC: Getting It Right

For any engineer, installer, or project owner, the safety and reliability of an electric panel bus bar hinge on its ampacity: the maximum current it can continuously handle without exceeding its temperature limit. Exceeding this limit is a direct path to catastrophic failure.

An undersized bus bar will overheat, leading to insulation breakdown, equipment damage, and a severe fire hazard. Ampacity is not a static value; it is a dynamic rating that must be calculated based on real-world installation conditions to ensure a safe, code-compliant system.

Key Factors Determining Ampacity

A bus bar's current-carrying capacity is determined by its physical characteristics and its operating environment.

- Cross-Sectional Area: A larger cross-sectional area provides more pathways for electron flow, reducing electrical resistance and heat generation. More area equals higher ampacity.

- Material: Copper's higher conductivity allows it to carry more current than an aluminum bar of the same dimensions.

- Ambient Temperature: The surrounding air temperature is a critical factor. A bus bar in a hot, enclosed panel cannot dissipate heat effectively, which significantly reduces its safe ampacity.

- Surface Finish: A dull or painted surface radiates heat more effectively than a polished one, which can slightly increase its ampacity rating.

Compliance with the National Electrical Code (NEC)

The National Electrical Code (NEC) provides the mandatory framework for safe electrical installations. While it does not offer a universal ampacity chart, it establishes critical requirements for bus bar installation and overcurrent protection.

For professionals, NEC Article 368 (Busways) and Article 408 (Switchboards, Switchgear, and Panelboards) are essential reading. These articles mandate requirements for:

- Sizing and Overcurrent Protection: Ensuring the bus bar is protected by a correctly rated circuit breaker or fuse.

- Support and Bracing: Specifying how bus bars must be secured to withstand the powerful magnetic forces of a short-circuit event.

- Clearances: Defining minimum safe distances between bus bars and other conductive surfaces to prevent arcing.

Compliance Watchout: The Derating Trap

A common and dangerous mistake is using a generic ampacity chart found online. These charts typically assume ideal open-air conditions (e.g., 25°C or 77°F), which are never present inside a sealed electrical enclosure. Failing to derate for higher ambient temperatures or for the proximity of multiple bars is a direct route to a failed inspection and an unsafe system. Always consult manufacturer specifications and NEC guidelines for the specific installation environment.

Adherence to the NEC is the only way to guarantee a safe, reliable, and inspectable system, whether it’s a residential panel or complex industrial switchgear.

How to Size Bus Bars for Commercial Projects

Sizing an electric panel bus bar for a large commercial or industrial project is a critical engineering task with no margin for error. For project managers and EPCs, the process involves detailed load calculations, applying safety derating factors, and ensuring full NEC compliance. An undersized bus bar leads to system failure; an oversized one wastes capital and valuable panel real estate.

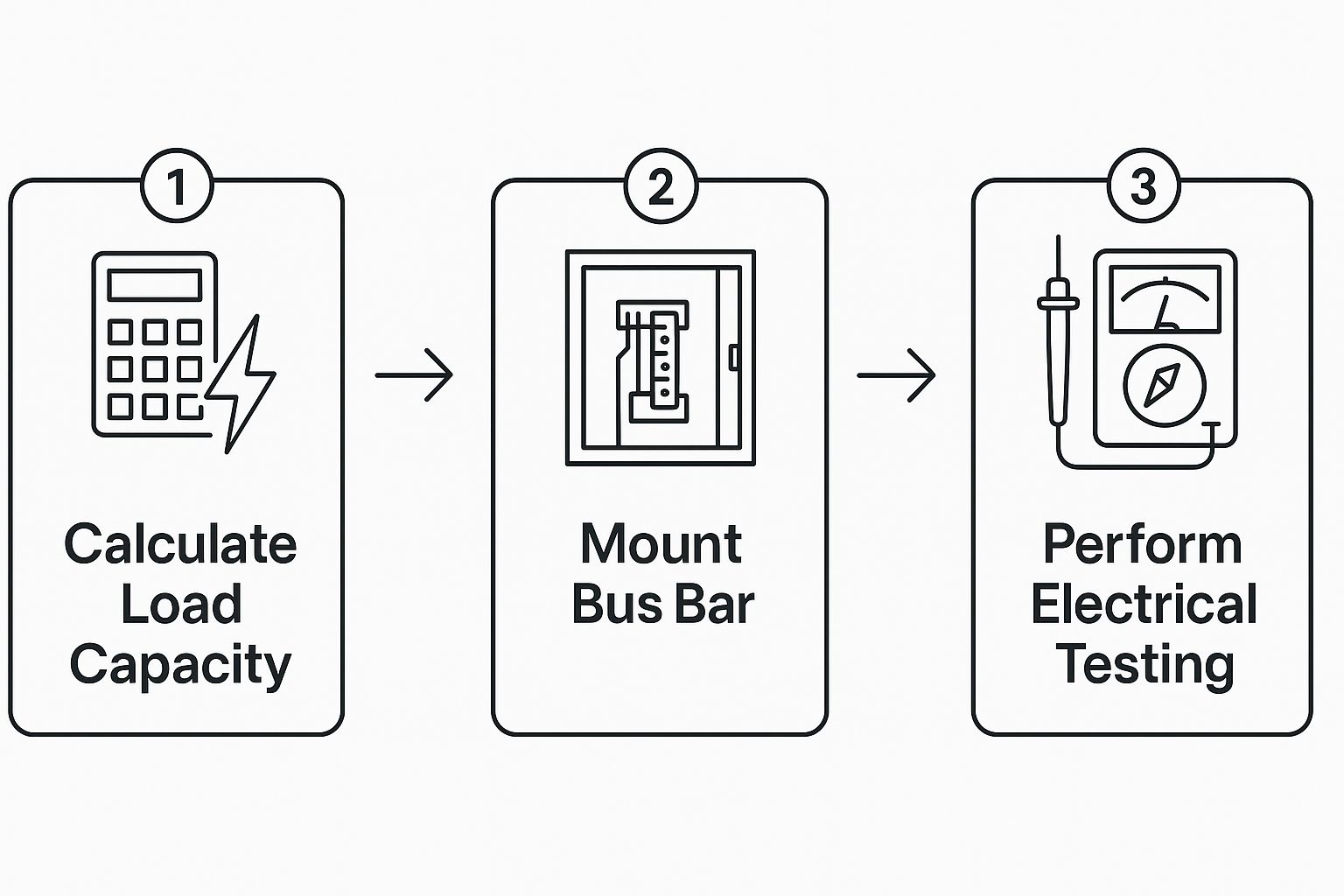

Let's walk through a real-world workflow for sizing the main bus bar for a 2000A commercial service entrance, ensuring a safe, efficient, and code-compliant result.

Step 1: Calculate the Total Connected Load

The first step is to determine the maximum demand the system will experience. This requires a comprehensive load calculation that includes every piece of equipment—HVAC systems, machinery, lighting, and receptacle loads—drawing power from the panel.

This is more than simple addition. The NEC mandates the application of demand factors to calculate a realistic peak load. For a quick review of the fundamentals, see our guide on understanding the relationship between kVA and kW. For this example, let's assume our detailed calculation confirms a 2000A main bus is required.

The complete sizing process, from initial calculation to final verification, is outlined below.

An accurate load calculation is the foundation of a safe and reliable electrical system.

Step 2: Apply Derating Factors

A bus bar's nameplate ampacity is determined under ideal laboratory conditions. In the real world, heat is the enemy, and you must apply derating factors to account for the actual operating environment inside the enclosure.

- Ambient Temperature: Manufacturer ratings are often based on a 30°C (86°F) ambient temperature. The bus bar's capacity must be derated for any installation in a hotter environment, such as a non-ventilated mechanical room.

- Enclosure Type: A ventilated enclosure allows for heat dissipation, whereas a sealed NEMA enclosure traps heat. The lack of airflow necessitates a lower ampacity rating.

- Bus Bar Proximity: Multiple bus bars installed close together radiate heat onto each other, reducing the cooling efficiency of each bar and requiring further derating.

Step 3: Verify Key Specifications for Procurement

With the derated amperage calculated, the next step is to create a detailed procurement checklist using manufacturer spec sheets. This ensures the ordered component meets all safety and performance requirements.

Procurement Watchout: Never select a bus bar based on ampacity alone. The Short-Circuit Current Rating (SCCR) is equally critical. The SCCR must be equal to or greater than the available fault current at the point of installation. An inadequate SCCR will result in a catastrophic failure during a short-circuit event.

Proper specification is crucial in a U.S. busbar market valued at USD 4.3 billion in 2024 and projected to exceed USD 7.4 billion by 2033, driven by the demand for safe, high-performance power distribution.

Procurement Checklist for a 2000A Commercial Bus Bar:

- Voltage Rating: Must match system voltage (e.g., 480/277V).

- Ampacity: Continuous current rating after applying all derating factors.

- Short-Circuit Current Rating (SCCR): Must meet or exceed the calculated available fault current.

- UL Listings: Must be UL listed for the application (e.g., UL 891 for switchboards).

- Material and Plating: Specify copper or aluminum with appropriate tin or silver plating for the operating environment.

Bus Bar Installation Best Practices

Correctly sizing an electric panel bus bar is only half the job. For electrical contractors and field installers, a flawless installation is non-negotiable for system safety, longevity, and code compliance. A perfectly specified bus bar can become a point of catastrophic failure if it is not installed with precision. The core of a successful installation lies in creating clean, secure, and properly torqued connections.

Creating Secure Electrical Joints

A reliable electrical joint begins with meticulous surface preparation. Any oxidation, oil, or debris on contact surfaces increases resistance and generates heat, which can lead to thermal runaway. Always clean contact points with a manufacturer-approved solvent and a lint-free cloth. For aluminum bus bars, using a wire brush immediately before termination is essential to break through the insulating oxide layer.

Proper torque is equally critical. This is not a task for guesswork; a calibrated torque wrench is mandatory.

Pro Tip: Overtightening is as damaging as undertightening. Excessive torque can deform the bus bar, stretch bolts beyond their elastic limit, and create micro-fractures, resulting in a weak joint destined for failure. Always adhere strictly to the manufacturer's specified torque values.

Maintaining Proper Clearances

Maintaining adequate spacing around bus bars is a fundamental safety requirement mandated by NEC and UL standards. These clearances prevent arcing between energized conductors or between a conductor and the grounded panel enclosure.

- Phase-to-Phase Clearance: The minimum distance between bus bars of different phases.

- Phase-to-Ground Clearance: The minimum distance between any energized bus bar and the grounded enclosure or other grounded components.

Failure to maintain these clearances creates a significant risk of a short circuit and a dangerous arc flash event. Verifying these distances during and after installation is a critical safety step. Faulty installation can lead to equipment destruction and serious injury. Learn more in our guide on how to prevent electrical fires.

Critical Installation Mistakes to Avoid

- Improper Surface Preparation: Skipping the cleaning step creates a high-resistance connection, a guaranteed future point of failure.

- Ignoring Torque Specifications: Using an impact wrench or guessing the torque is a recipe for a failed connection. Use a calibrated torque wrench every time.

- Inadequate Bracing and Support: Bus bars must be properly supported to withstand the violent magnetic forces of a short circuit. Insufficient bracing can lead to bending or breaking.

- Drilling Unauthorized Holes: Field-drilling holes alters the bus bar's cross-sectional area, reducing its ampacity and compromising its structural integrity and SCCR.

Expert Answers to Common Bus Bar Questions

Here are answers to the most common questions our technical team receives from professionals in the field.

What Is the Main Advantage of a Copper Bus Bar Over an Aluminum One?

The primary advantages are superior conductivity and mechanical strength. Copper's higher conductivity allows a copper bus bar to be physically smaller than an aluminum one while carrying the same current. This is a critical benefit in high-density panels where space is limited. Although aluminum is lighter and has a lower initial cost, copper's high resistance to oxidation ensures more reliable, low-resistance connections over the system's lifetime, especially in harsh industrial environments where failures are not an option.

How Does Ambient Temperature Affect Bus Bar Ampacity?

A bus bar generates heat as current flows through it and must dissipate this heat into the surrounding air to prevent overheating. Its ampacity, or maximum safe current rating, is directly dependent on its ability to cool itself. When the ambient temperature is high—such as inside a non-ventilated enclosure exposed to sunlight—the bus bar cannot cool effectively. Therefore, its ampacity must be "derated" (reduced) to ensure safe operation. Following NEC and manufacturer derating tables for temperature is a mandatory step for a safe and compliant installation.

Why Is SCCR Important for Bus Bars?

SCCR (Short-Circuit Current Rating) is one of the most critical safety specifications for any component in an electrical panel. It defines the maximum fault current a bus bar can withstand without catastrophic failure, such as melting, deforming, or causing an arc flash. During a short circuit, the electromechanical forces are immense. A bus bar with an adequate SCCR and proper bracing is engineered to survive these forces long enough for the upstream overcurrent protection device (breaker or fuse) to interrupt the fault. Specifying the correct SCCR is a life-safety requirement mandated by code to protect both personnel and equipment.

From a simple panel upgrade to a complex industrial switchgear installation, specifying the right components is critical to project success. At Portlandia Electric Supply, we provide access to a deep inventory of top-tier bus bars, breakers, and panel components from leading manufacturers. Our NABCEP-certified design team and logistics experts ensure your project meets all performance, compliance, and timeline requirements with solutions like bundled freight and rapid quoting.