How to Calculate Electrical Load: A Pro's Guide for Installers & EPCs

Share

Calculating an electrical load is critical arithmetic for any project: add up the wattage of every light, appliance, and piece of equipment, then apply National Electrical Code (NEC) demand factors to account for non-concurrent operation. For electrical contractors, EPCs, and developers, this isn't just about math; it's about project viability. A precise calculation prevents failed inspections, undersized panels, and costly change orders that destroy profitability.

This guide provides an actionable framework for calculating electrical loads correctly, ensuring the systems you design and install are safe, code-compliant, and built to perform. The core formula is simple: Watts = Volts x Amps. Mastering its application is non-negotiable for correctly sizing breakers, wiring, and main service panels for residential and commercial projects.

Why Accurate Electrical Load Calculation Is Mission-Critical

Let's be clear: getting a load calculation wrong isn't a small mistake. It's a project-killer. An inaccurate calculation leads directly to failed inspections, undersized panels that can't handle real-world demand, and expensive change orders that tank your profitability and timeline.

This guide is for the pros in the trenches—installers, EPCs, developers, and facility managers—who know precision is non-negotiable. It directly impacts project safety, budget, and compliance at every stage. We’ll focus on what you need in the field: how to apply core concepts like Volts, Amps, and Watts to correctly size breakers, conductors, and transformers without guesswork.

Critical Mistakes: The Cost of Inaccurate Calculations

It’s tempting to oversize a system "just to be safe," but this inflates project costs with larger, more expensive switchgear and conductors than necessary.

The flip side is far worse. Undersizing a system is a massive liability. It creates a fire hazard and sets up the client for constant, frustrating nuisance tripping from overloaded circuits. A single inaccurate calculation sends ripples through the entire project, creating delays and eroding your bottom line.

Compliance Watchout: A flawed load calculation is one of the top reasons for a red tag from an inspector. This halts work, requires costly engineering rework, and damages your reputation with both the client and the local AHJ (Authority Having Jurisdiction).

The Role of Load Calculation in Project Success

A correct load calculation is the bedrock of any reliable, code-compliant electrical system. For contractors and developers, this is about more than just passing inspection; it’s about building a reputation for delivering safe, high-performance systems.

- Ensuring Safety and Compliance (UL & NEC): Proper system sizing prevents dangerous overheating and ensures you're following NEC standards to the letter. It’s about protecting people and property.

- Managing Project Budgets: Accuracy here is money in the bank. You stop overspending on oversized gear and avoid the painful, costly rework that comes from under-building the system.

- Planning for Future Needs: A smart load analysis always looks ahead. You can account for future upgrades like EV charging stations, heat pumps, or battery storage systems from brands like FranklinWH or BYD, delivering long-term value that clients appreciate.

Mastering how to calculate an electrical load is a non-negotiable skill. Get it right from the start, and you protect your timeline, your budget, and your professional credibility.

Mastering the Core Formulas and NEC Standards

To size a system correctly, you can't just tally up a list of appliances. You need a rock-solid understanding of the core formulas and the National Electrical Code (NEC) standards that govern every safe, compliant installation. This isn't about memorizing a textbook—it's about having the right tools in your belt to make defensible calculations on the job.

It all starts with two non-negotiable formulas: Ohm's Law and the Power Formula. These are the absolute bedrock of both electrical theory and real-world application.

- Ohm's Law (V = I x R): This defines the relationship between voltage (V), current (I), and resistance (R) in any circuit. It's fundamental.

- Power Formula (P = V x I): This is your go-to for load calculation. It lets you translate an appliance's voltage and amperage draw directly into its power consumption in watts (P).

For example, a water heater rated for 240V and pulling 30A consumes 7,200 watts (or 7.2 kW). This quick math is the first step in sizing the right breaker and wire for that single circuit. Once you have this down, you can scale up from individual circuits to the entire service. If you want to dig deeper into the math, check out our guide on how to properly calculate power consumption.

Putting the Code into Practice with NEC Article 220

While formulas give you the raw horsepower, NEC Article 220 lays down the rules of the road. This section is the final word on calculating branch-circuit, feeder, and service loads. It’s what keeps us from dangerously oversizing or—even worse—undersizing systems by introducing "demand factors."

Simply put, demand factors are the NEC's way of acknowledging that not everything in a building runs at full tilt, 24/7.

The code provides clear guidelines, like assigning a baseline of 180 volt-amperes (VA) per general-purpose receptacle. For heavy hitters like HVAC systems—often the single largest load—you have to be much more precise, as their consumption varies dramatically. After you’ve added up all the individual loads, these demand factors are applied to get a realistic total, preventing you from installing a service that's way bigger and more expensive than necessary.

To help you keep these straight, here's a quick reference table of common demand factors straight from the codebook.

Key NEC Demand Factors for Load Calculation

This table summarizes some of the most common demand factors from NEC Article 220. It's a handy cheat sheet for applying diversification to your load calculations and ensuring you're not oversizing your service equipment based on unrealistic assumptions.

| Load Type | NEC Article Reference | Demand Factor Application |

|---|---|---|

| General Lighting | 220.42 | First 3,000 VA at 100%; remaining from 3,001 to 120,000 VA at 35%; excess over 120,000 VA at 25%. |

| General-Use Receptacles | 220.44 | First 10 kVA at 100%; remainder over 10 kVA at 50%. |

| Household Electric Ranges | Table 220.55 | Varies by number and rating of appliances. For one 12 kW range, demand is 8 kW. |

| Fixed Appliance Loads | 220.53 | 75% demand factor applies if there are four or more fixed appliances on the same feeder. |

| Largest Motor Load | 220.50 | The largest motor load must be calculated at 125%. |

Using this table helps translate the code's theory into practical, compliant numbers for your project. Remember to always consult the latest edition of the NEC for specific applications and any local amendments.

Pro Tip for Installers: The nameplate rating on equipment is your source of truth. Always use it for your calculations, especially for anything with a motor, like an air compressor or well pump. It's not just a best practice; it's an NEC requirement that ensures safety and reliability.

Applying these standards is what separates a professional, engineered system from a back-of-the-napkin guess. It ensures your installation is safe, code-compliant, and built to perform for the long haul.

A Practical Walkthrough of a Residential Load Calculation

Formulas are great, but seeing a real-world calculation is where the theory becomes practice. Let's walk through the process using the standard method from NEC Article 220. We'll size the main service panel for a typical 2,000-square-foot single-family home.

First up are the general loads. Think of these as the baseline for any house—the lights, countertop outlets, and laundry hookups that are always part of the equation.

General Lighting and Receptacle Loads

We start with the general lighting load, which is directly tied to the home's size. The NEC specifies a calculation of 3 Volt-Amperes (VA) per square foot.

- Calculation: 2,000 sq. ft. x 3 VA/sq. ft. = 6,000 VA

Next are the small appliance circuits for the kitchen and dining area. The code requires a minimum of two 20-amp circuits, and each is factored in at 1,500 VA.

- Calculation: 2 circuits x 1,500 VA/circuit = 3,000 VA

And we can't forget the laundry room. A dedicated circuit is mandatory here, adding another 1,500 VA to our running total.

- Calculation: 1 circuit x 1,500 VA = 1,500 VA

Add it all up, and our total connected general load is 10,500 VA (6,000 + 3,000 + 1,500).

Applying Demand Factors to General Loads

Now for the smart part. The NEC knows you're not going to run every single light and plug-in appliance at the same time. This is where demand factors come in, letting us apply a more realistic load.

The rule is to take the first 3,000 VA at 100% and the rest at a much lower 35%.

- First 3,000 VA: 3,000 VA x 100% = 3,000 VA

- Remaining VA: (10,500 VA - 3,000 VA) = 7,500 VA

- Remaining at 35%: 7,500 VA x 35% = 2,625 VA

- Total General Demand Load: 3,000 VA + 2,625 VA = 5,625 VA

Interestingly, this kind of statistical modeling isn't new. The idea of forecasting electrical usage has been around since the early days of the grid. As far back as 1973, organizations like the International Union of Producers and Distributors of Electrical Energy (UNIPEDE) were publishing sophisticated papers on the topic. You can find some fascinating historical perspectives on these early statistical load modeling techniques over at VTT Publications.

Adding Fixed Appliances and HVAC

With our baseline demand figured out, it's time to add the big stuff—the fixed appliances. We'll use the nameplate ratings for these. Let’s assume this home has:

- Electric Range: 12,000 VA

- Electric Dryer: 5,000 VA

- Dishwasher: 1,200 VA

- Water Heater: 4,500 VA

- HVAC System: 6,000 VA (we always use the larger of the heating or cooling load)

The code gives us a break on some of these, too. A single 12,000 VA range, for example, can be calculated at a reduced 8,000 VA. If we have four or more fixed appliances (not including the range or HVAC), we can apply a 75% demand factor to that group. For this example, we’ll calculate them individually to keep it straightforward.

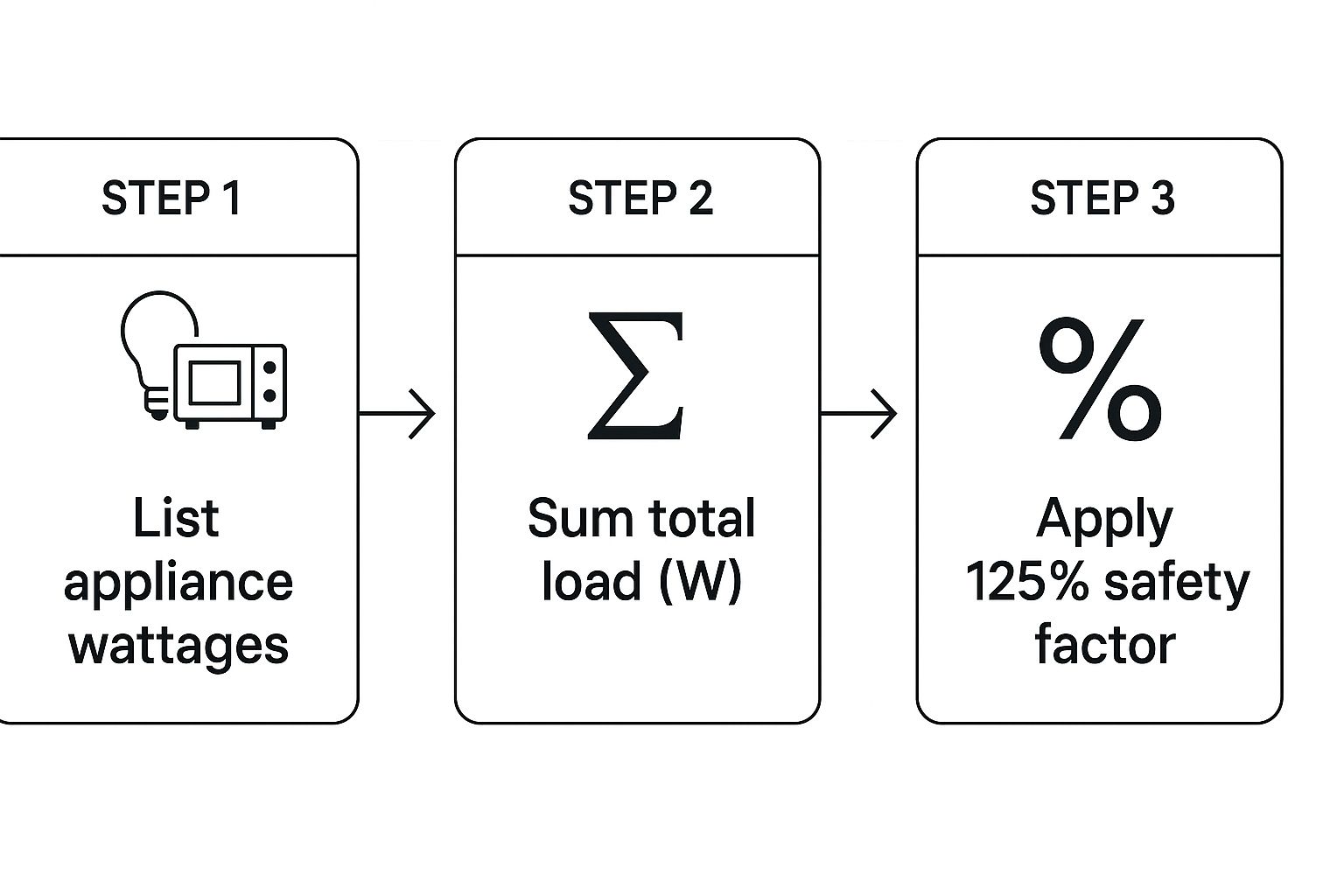

This simple infographic helps visualize the core workflow.

It really just boils down to listing your loads, applying the right factors, and adding it all up.

Final Calculation and Service Sizing

Okay, let's bring all our numbers together for the final tally.

- General Demand Load: 5,625 VA

- Range (Demand): 8,000 VA

- Dryer: 5,000 VA

- Dishwasher: 1,200 VA

- Water Heater: 4,500 VA

- HVAC System: 6,000 VA

Total Calculated Load: 5,625 + 8,000 + 5,000 + 1,200 + 4,500 + 6,000 = 30,325 VA

To figure out the service size in amps, we just divide this total by the voltage of a standard residential service, which is 240V.

Amperage: 30,325 VA / 240V = 126.35 Amps

So, what does this number tell us? It means a 125A panel is just under what's required. You always have to go to the next standard size up. In this case, a 150A service is the correct choice, giving the homeowner plenty of power with a safe buffer. You could even argue for a 200A panel to leave room for future upgrades like a hot tub or an EV charger.

Navigating Commercial and Industrial Load Calculations

When you make the jump from residential to commercial projects, you’re stepping into a whole new world of complexity. For the EPCs, facility managers, and contractors managing these builds, it’s not just about tallying up a few appliances anymore. We're talking about diverse loads like three-phase motors, massive HVAC systems, and highly specialized industrial machinery.

Getting this right demands a much more rigorous approach.

Unlike residential work where most loads are intermittent, commercial jobs require a crystal-clear distinction between continuous and non-continuous loads. A continuous load is anything you expect to be running for three hours or more straight—think of the lighting in a big retail store. The NEC is very specific here: it mandates sizing branch circuits and feeders for these loads to 125% of the load. This isn't just a suggestion; it's a critical safety measure to prevent overheating and keep the system stable.

Mess up this distinction, and you're looking at failed inspections, equipment burning out way too soon, and some serious safety hazards.

A Focus on Nameplate Ratings and Demand Factors

In the commercial space, forget about using generalized VA-per-square-foot estimates for anything beyond basic lighting and outlets. It just won’t fly. Every single piece of equipment—from the HVAC units on the roof to the walk-in coolers in a restaurant kitchen—must be calculated using its exact nameplate rating.

That nameplate is your source of truth. It gives you the precise voltage, amperage, and sometimes the power factor you need for an accurate calculation. If you want to get a better handle on how these values interact, especially with motor-driven equipment, check out our pro guide on converting kVA to kW. It’s a great resource.

The demand factors used in commercial settings are also far more granular and specific. They’re designed to account for the varied, and often predictable, operational schedules in a commercial building. This helps ensure you're not oversizing expensive transformers and switchgear based on the wildly unrealistic assumption that every single load will be maxed out at the same time.

For a clearer picture, it helps to see the differences side-by-side. Residential and commercial calculations follow different rules and focus on different priorities.

Residential vs Commercial Load Calculation Key Differences

This table breaks down the core differences you'll encounter when approaching a residential project versus a commercial one, from the types of loads to the specific NEC articles you'll be referencing.

| Consideration | Residential Projects | Commercial Projects |

|---|---|---|

| Primary Calculation Method | Standard Method (NEC Article 220) | Based on nameplate ratings and specific NEC rules |

| Typical Loads | Lighting, receptacles, range, dryer, water heater, HVAC | Three-phase motors, large HVAC, specialized machinery, extensive lighting |

| Load Type Focus | General loads with some specific appliance calculations | Strict distinction between continuous and non-continuous loads |

| Demand Factors | Standardized NEC tables for dwellings | Highly specific factors for kitchens, motors, lighting, etc. |

| Voltage Systems | Typically 120/240V single-phase | Often 120/208V or 277/480V three-phase |

| Future Planning | Optional, but good practice | Critical; often includes 20-25% spare capacity |

Understanding these distinctions is key to applying the right methods and ensuring a safe, compliant, and efficient electrical system, no matter the project scale.

Planning for Future Growth: A Critical Step

One of the most common—and most expensive—mistakes on commercial jobs is a failure to plan for the future. Your initial load calculation should always include a buffer for anticipated growth. Is the client planning to add more production machinery down the line? Expand the office? Install a bank of EV chargers? You need to ask these questions.

For Developers & EPCs: Building in 20-25% of spare capacity into the service and distribution panels is one of the smartest investments you can make. It saves your client from the massive headache and expense of a complete service upgrade in just a few years.

This foresight is also crucial when clients are lining up their finances. A solid load calculation helps them understand the true infrastructure costs before they start the process of financing construction equipment. Sizing it right from the start protects your client's investment and shows you're thinking ahead.

Advanced Load Profiling for Modern Energy Systems

Old-school, static calculations are insufficient for modern energy projects incorporating solar, EV charging, or battery storage. To design high-performance systems, you must leverage load profiling—the process of analyzing energy usage patterns over time to understand how and when a building truly needs power.

This dynamic approach is essential. Understanding a building’s unique load shape is what allows you to correctly size inverters from brands like Sungrow or Fronius, battery systems like the FranklinWH aPower, and even backup generators from trusted names like Cummins. This is how you maximize project ROI and guarantee the system delivers on its performance promises.

Uncovering Opportunities with Interval Data

Instead of a single, flat number, a load profile provides a granular picture of demand, often broken down into 15-minute intervals. This level of detail is exactly what you need to spot opportunities for peak shaving and load shifting—strategies that can dramatically reduce a facility's energy costs by avoiding high utility demand charges.

For complex systems like microgrids, this data is non-negotiable. Accurate load profiling is the absolute foundation for maximizing the efficiency of microgrids.

The granularity of this data is a game-changer. A deep-dive analysis might track those 15-minute intervals over a full week, giving you 672 data points (96 intervals/day × 7 days). This captures all the peaks and valleys that traditional methods completely miss, allowing for far more accurate system modeling.

Real-World Application for Developers and Facility Managers

Consider a commercial building that experiences a massive energy spike every weekday afternoon from 2 PM to 4 PM as all HVAC units run at maximum capacity. A static calculation would simply lump that HVAC load into the total.

A load profile, however, pinpoints that specific, predictable peak. With that insight, a developer can design a battery storage system that charges overnight when electricity is cheap and then discharges during that two-hour window. It effectively "shaves" the peak demand right off the utility bill. This is a core skill for anyone tackling an off-grid solar system design, where you have to account for every single watt-hour.

For project developers and facility managers, load profiling is the bridge between a good system and a truly optimized one. It provides the data-driven intelligence needed to design energy solutions that actively manage costs and enhance grid resilience.

Common Load Calculation Questions Answered

Even when you have the formulas and the codebook right in front of you, the real world always throws a curveball. Let's tackle some of the most common questions we hear from installers, developers, and facility managers when they're running the numbers. These are the practical, in-the-field issues that can stall a project if you don't have a clear answer.

How Do You Account for Future Loads?

This is a big one. One of the classic mistakes is sizing a system only for what a building needs today. A professional load calculation always plans for tomorrow. For commercial jobs, the industry best practice is to add a 20-25% capacity buffer right on top of your final calculated load.

In a residential setting, this means thinking about the upgrades homeowners are actually making:

- EV Chargers: A Level 2 charger is a significant draw, adding 7,000 to 12,000 VA.

- Heat Pump Water Heaters: These are getting more common and often need their own circuit.

- Hot Tubs or Pools: These are massive electrical loads that you absolutely have to plan for.

If you don't build in that extra room, you're setting the owner up for a costly and disruptive service upgrade down the road. Factoring in this buffer from day one is a hallmark of quality work.

What Is the Difference Between Connected Load and Demand Load?

Getting this right is fundamental. The connected load is the absolute theoretical maximum—it's what you'd get if you added up the nameplate rating of every single appliance and piece of equipment and imagined them all running at full tilt, at the same time.

The demand load, on the other hand, is the real-world number. It's the power you actually need after applying the NEC's demand factors, which recognize that nobody runs everything at once. Your service and feeder sizing must be based on the calculated demand load.

The demand load is the number that matters for code-compliant sizing. Using the total connected load will almost always lead to an unnecessarily oversized and overpriced system.

When Should You Use the Optional Method?

The NEC gives us an "Optional Method" under Article 220.82 specifically for single-family homes. It's often a lot faster than the Standard Method because it relies on a more straightforward, percentage-based approach.

Generally, you can use the Optional Method for homes with a service of 100A or larger. It's particularly useful when a house has a lot of electric heating and air-conditioning. But here's the key: always check with your local jurisdiction first. Some municipalities have their own rules and may not permit it.

Ready to tackle your next project with the right materials and expert support? At Portlandia Electric Supply, we provide everything from panels and breakers to complete solar and storage kits, backed by in-house design and logistics expertise. https://portlandiaelectric.supply