Solar Panel Maintenance Guide for Peak Performance & Project ROI

Who This Guide Is For: Solar installers, EPCs, asset managers, and savvy homeowners responsible for maximizing the performance and financial returns of solar energy systems.

What You'll Achieve: Move from reactive repairs to a proactive, data-driven maintenance strategy that protects your investment, ensures NEC compliance, and maximizes long-term energy production.

Ignoring solar panel maintenance is a direct path to revenue loss. For professionals, it's a critical failure in asset management; for homeowners, it's leaving money on the table. Environmental buildup like dust and pollen is the obvious culprit, but hidden electrical faults and component degradation are silent killers of system output. This guide provides an actionable framework for protecting your investment.

Protecting Your Solar Investment: From Asset Management to Field Reality

For asset owners, developers, and EPCs, maintenance isn't just an operational cost; it's fundamental to meeting pro forma projections. The financial stakes are far higher than a simple cleaning bill. Small, preventable issues have a documented history of snowballing into significant revenue loss, ultimately shortening the lifespan of a multi-decade asset. The "set it and forget it" approach is a direct threat to your ROI.

Recent industry analysis confirms this reality: the average solar asset worldwide is underperforming due to preventable equipment issues, leading to a potential revenue loss of $5,720 per megawatt direct current (MWdc) annually. That figure is up 15% from the prior year, highlighting a growing trend of financial loss from deferred maintenance. You can review the complete dataset in the full global solar report.

Environmental and Physical Risks to Your Bottom Line

The most obvious threat to system output is environmental debris. Even a thin layer of dust, pollen, or industrial soot can slash a panel's efficiency. But the real operational dangers go far beyond surface grime.

- Bird Droppings and Debris: This classic culprit creates "hot spots" where shaded cells resist energy flow from their neighbors. This generates intense, localized heat that can permanently damage the panel's internal structure (backsheet degradation).

- Hidden Electrical Faults: Loose wiring, corroded connections, and failing inverters are silent performance killers. They often go unnoticed without professional inspection, quietly eroding daily output and posing a latent fire risk under NEC guidelines.

- Microcracks and Physical Damage: Caused by everything from hail to rough handling during installation, these nearly invisible cracks in solar cells propagate over time. Routine inspections are the only way to catch them before they lead to catastrophic string or module failure.

Pro Tip for Installers: Documenting a clear maintenance schedule for your client isn't just good customer service—it's risk management. It sets proper expectations and can protect you from future claims of underperformance.

Actionable Annual Maintenance Schedule

A repeatable maintenance schedule is essential for staying ahead of potential issues. This table breaks down critical tasks by frequency, clarifying what professionals must handle versus what a system owner can safely monitor.

| Frequency | Task for Installers and Professionals | Task for Homeowners (DIY-Friendly) | Key Objective |

|---|---|---|---|

| Quarterly | Visual inspection of racking and mounting hardware for torque and corrosion. | Clear debris (leaves, twigs) from around panels and inverter. | Ensure structural integrity and prevent shading/fire hazards. |

| Semi-Annually | Professional panel cleaning, especially in dusty or agricultural areas. | Rinse panels with a hose (if safe and accessible from the ground). | Maximize light absorption and energy production. |

| Annually | Perform full electrical system check (inverter, connections, wiring) with torque checks and thermal imaging. | Visually inspect panels from the ground for cracks, discoloration, or damage. | Detect and fix electrical faults per NEC; identify physical wear. |

| Bi-Annually | Conduct thermal imaging scans to identify hot spots and cell-level faults. | Review energy production data for anomalies or trends. | Pinpoint failing cells and underperforming strings before failure. |

This schedule provides a solid framework for keeping solar assets in peak condition, ensuring they deliver the performance and financial returns projected in the original system design.

Your Essential Solar Panel Inspection Checklist

A proactive inspection schedule is the backbone of effective solar panel maintenance, designed to catch minor issues before they escalate into costly failures. The required depth of inspection varies significantly between a system owner's visual check and a professional's diagnostic assessment.

For any homeowner, safety is paramount. Your inspection must be strictly limited to what can be observed from the ground. Climbing on a roof without professional training and safety equipment is a serious risk.

The Homeowner Ground-Level Visual Check

This is a quick, safe check you can perform monthly to identify obvious problems that warrant a professional service call.

- Panel Surface: Scan panels for clear cracks, chips, or discoloration. Look for heavy buildup of grime, leaves, or bird droppings that rain hasn't washed away.

- Mounting and Racking: Observe the racking system. Does anything look misaligned? Are any bolts or components visibly loose or shifting? The entire structure should appear solid.

- Wiring: Check visible wiring and conduits. Look for signs of animal damage or wires that have come loose from their clips and are now sagging.

- Inverter Area: Ensure the space around your inverter is clear of debris. Glance at the display for error codes or warning lights—note down any codes before contacting your installer.

The Professional Installer and EPC Diagnostic Checklist

For installers, EPCs, and O&M crews, the annual inspection is a comprehensive diagnostic to verify system performance and compliance with National Electrical Code (NEC) standards.

Critical Safety Warning: Always follow proper lockout/tagout (LOTO) procedures to completely de-energize the system before touching any component. A live solar array presents a lethal electrocution risk. There are no shortcuts.

A professional-grade inspection must cover:

- Racking and Structural Integrity: Physically check torque on all mounting bolts against manufacturer specifications. Verify the racking is secure, properly grounded, and shows no signs of corrosion or metal fatigue that could compromise its UL listing.

- Wiring and Connections: Open junction boxes to inspect for moisture intrusion, corrosion, or loose connections. Use a thermal imaging camera to scan wiring, combiners, and disconnects for hot spots, which indicate high resistance and potential failure points.

- Inverter Health Check: Run a full diagnostic on the inverter. Pull fault logs, analyze performance data against historical benchmarks, and ensure firmware is up-to-date. Clean all air intakes and fans to prevent overheating, a primary cause of inverter failure.

- Module-Level Inspection: Go beyond visual checks. Utilize advanced tools to identify microcracks or hidden hot spots. Techniques like multispectral imaging for panel health analysis are crucial for utility-scale assets. You must also know how to test solar panel output to validate that module performance aligns with datasheet specifications.

Mastering Solar Panel Cleaning Techniques and Tools

Keeping solar panels clean is fundamental, but improper cleaning can cause more harm than good. Using a pressure washer or household detergents are fast tracks to causing permanent damage.

Aggressive methods can strip the anti-reflective coating, create micro-scratches that degrade performance, and may void the manufacturer's warranty. The goal is to remove grime gently to boost efficiency without creating new, costly problems.

The Right Procedure for a Safe and Effective Clean

Timing is critical. Never wash hot panels with cool water, as this can cause thermal shock—a rapid temperature change leading to microscopic cracks in the glass. Plan cleaning for cooler parts of the day, such as early morning or late evening.

A methodical approach is essential.

First, shut down the entire system following the manufacturer's instructions. This is a non-negotiable safety step to eliminate electrical hazards.

Next, rinse the panels with a standard garden hose to remove loose dirt and grit that could scratch the glass during scrubbing.

Then, use a soft-bristle brush on an extension pole to gently scrub the surface. A bucket of clean water is often sufficient, but a small amount of a pH-neutral, panel-specific cleaner can be used for stubborn grime.

Finally, rinse thoroughly to remove all soap residue. For a professional, spot-free finish, use deionized or purified water for the final rinse to prevent mineral deposits from hard water.

Essential Tools of the Trade

You don't need a large inventory of equipment, just the right tools for the job.

- Soft-Bristle Brush: A non-abrasive brush, ideally on a telescoping pole, is essential for scrubbing without damaging the panel's surface.

- High-Quality Squeegee: A professional-grade squeegee is crucial for preventing streaks and mineral spots as the panels dry.

- Hose with Nozzle: A standard garden hose with an adjustable nozzle allows you to control water pressure and maintain a gentle flow.

For a deeper dive into professional-grade equipment, check out our guide on the best solar panel cleaning equipment. We cover everything from advanced water-fed poles to automated cleaning systems.

While panel cleaning is vital, consider the surrounding environment. Professional roof cleaning services can create a cleaner environment for your system, preventing issues like moss and algae from encroaching on your array. By adhering to these proven techniques, you will maintain your solar panels in peak condition and maximize their output for years.

Inspecting Your PV System Beyond the Panels

A high-performing solar array depends on more than just clean panels. Many performance issues and failures originate in the Balance of System (BOS)—the essential hardware that supports, connects, and converts the energy your panels generate. A panel-only focus is a critical oversight.

A proper system health check requires a holistic view. It involves regularly inspecting the components doing the heavy lifting behind the scenes. For a refresher on these components, our guide to solar panel system components is an excellent resource.

Inverter and Electrical Health Checks

The inverter is the brain of your solar operation. Tier 1 brands like Sungrow and Fronius have robust built-in diagnostics, but they are not "set and forget" hardware. The first step is to check the inverter's display or online monitoring portal for fault logs or error codes. These codes are your earliest warning of issues that can tank production.

After a digital check, a physical inspection is necessary.

- Check Connections: Ensure every electrical connection at the inverter, combiner box, and disconnects is torqued to spec. A loose connection creates resistance, generating heat that leads to power loss and, in a worst-case scenario, a fire hazard.

- Look for Corrosion: Inspect terminals and wiring for any signs of corrosion, especially in humid or coastal climates where salt air can accelerate degradation.

- Verify Ventilation: Confirm that the inverter’s cooling fans and vents are clear of dust, leaves, and other debris. Overheating is a leading cause of inverter failure and reduced lifespan.

Battery Storage and Structural Integrity

If your system includes energy storage from brands like FranklinWH, the battery unit is another critical checkpoint. Confirm it is operating within its recommended temperature range and that its state of charge is cycling correctly. Look for physical signs of trouble, like swelling or cracks in the casing.

Finally, inspect the foundation of the array: the racking and mounting hardware. This is non-negotiable in areas with high winds or heavy snow loads. If accessible, walk the array and physically check for loose bolts, shifting clamps, or signs of metal fatigue. The structural integrity of the racking is what protects your investment from the elements.

This comprehensive inspection is more vital than ever. Renewables recently added a record-breaking 585 GW of new power capacity worldwide, with solar leading the charge. With so many assets coming online, system-wide checks are essential for effective management. You can review these global renewable energy growth trends to understand the scale of industry expansion.

Long-Term Strategies for Your Aging Solar System

Once a solar installation surpasses the 15-year mark, the maintenance strategy must evolve. While routine cleaning and inspections remain foundational, the focus shifts toward strategic decisions about the asset's future.

Performance degradation in older systems is inevitable, but it doesn't signify the end of their revenue-generating lifespan. Smart asset owners transition from simple upkeep to strategic management, shifting the conversation from "fix it" to "revitalize it."

Is Repowering the Right Move?

Instead of facing the high costs and logistical challenges of full decommissioning, repowering has emerged as a smarter, more profitable strategy.

Repowering is a strategic refurbishment of an older solar plant designed to restore or significantly boost its original output. This comprehensive upgrade can include:

- Replacing old, degraded modules with modern, higher-efficiency panels.

- Upgrading legacy inverters to new models with improved performance and advanced monitoring.

- Modernizing racking and wiring to meet current codes and enhance reliability.

Financially, repowering breathes new life into an asset, increases its energy production, and maximizes the long-term return on the original investment.

Repair vs. Repower: A Data-Driven Decision

The decision of when and how to intervene hinges on performance data. A small, temporary dip in output often points to a simple issue correctable with basic maintenance. However, a significant, sustained drop in production is a red flag for a deeper problem that requires professional assessment and a serious look at repowering.

This decision-making process is where asset managers create significant value. The following matrix outlines the factors that should guide the choice between a targeted repair and a full-system repowering.

Repair vs. Repower Decision Matrix

| Factor | Consider Repairing If... | Consider Repowering If... | Key Financial Indicator |

|---|---|---|---|

| System Age | The system is less than 10-12 years old. | The system is 15+ years old and approaching end-of-life. | Levelized Cost of Energy (LCOE) |

| Performance Degradation | A few isolated components are failing or underperforming. | System-wide degradation is significant (15-20% or more). | Net Present Value (NPV) of future cash flows |

| Component Availability | Original or compatible replacement parts are readily available. | Key components like inverters are obsolete and unsupported. | Return on Investment (ROI) of the upgrade |

| Technology Gains | Current technology offers only marginal efficiency gains. | New panels/inverters offer a major boost in efficiency (>25%). | Internal Rate of Return (IRR) |

This matrix provides a framework for making a data-driven choice that maximizes the asset's long-term value.

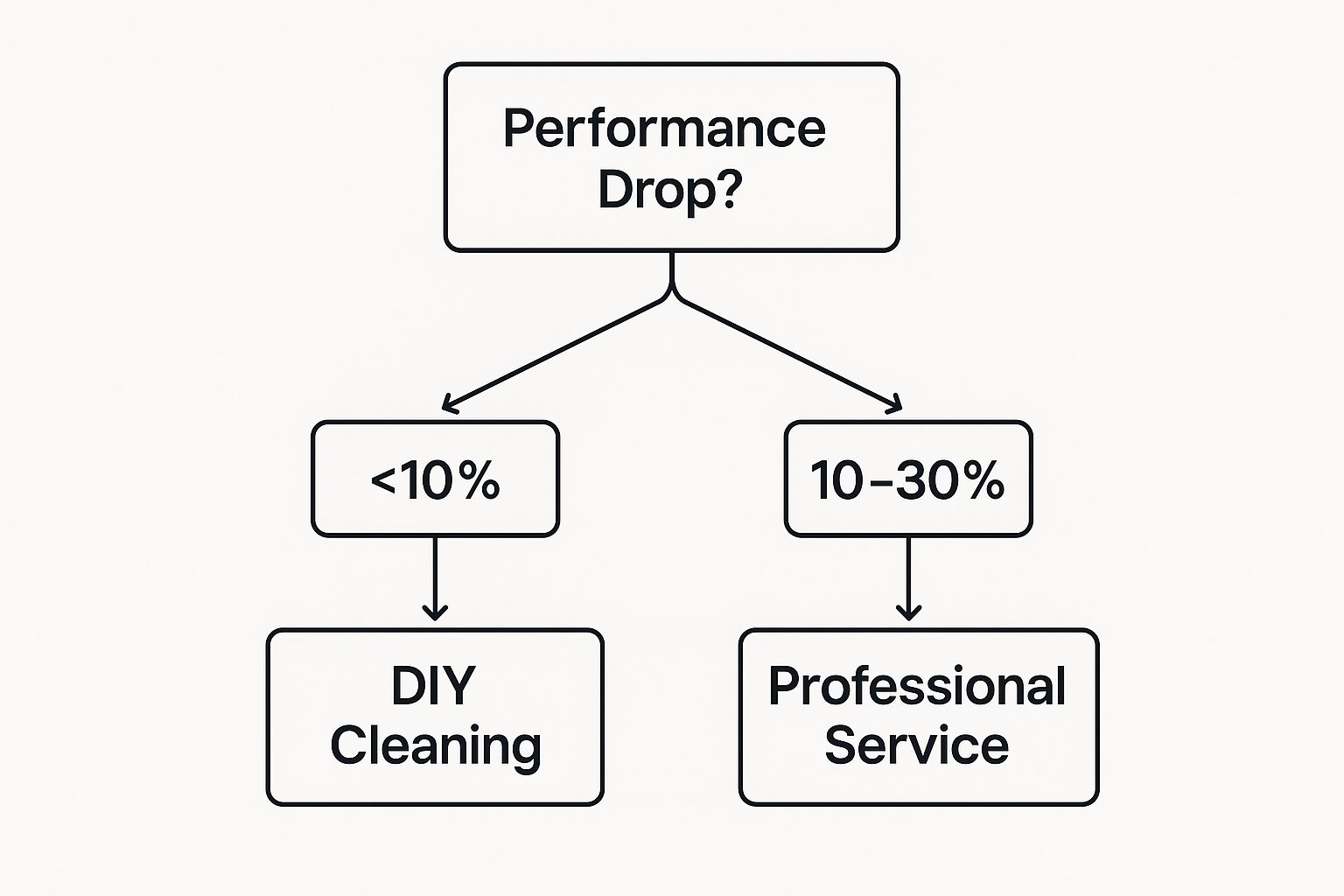

This infographic outlines the action thresholds, guiding you from simple DIY checks to professional intervention.

Performance data is your most critical tool. A sudden performance drop of over 30% is a massive red flag indicating that simple cleaning is insufficient and expert diagnostics are required.

The scale of global solar expansion means a wave of installations is now reaching the critical 15- to 20-year mark, fueling the repowering trend. Asset owners are wisely seeking to extract maximum value from existing infrastructure. In fact, many utility-scale systems are being repowered after just 12 to 15 years to capitalize on new technology, a testament to how global PV markets are adapting to lifecycle challenges. By treating your aging solar system as a strategic asset, you can ensure it remains a productive investment.

Answering Your Top Solar Maintenance Questions

Getting straight answers to common maintenance questions is crucial for protecting your solar investment. Here are the most frequent inquiries from system owners and professionals.

How Often Should I Really Clean My Solar Panels?

This depends entirely on your site's environmental conditions. For most systems in typical suburban or commercial locations, a professional cleaning once or twice a year is sufficient.

However, if your array is located in an area with heavy pollen, adjacent to agriculture, or in a dusty desert climate, quarterly cleanings may be necessary to prevent soiling losses that can reduce production by 5-10% or more. The definitive answer lies in your monitoring data. A sustained drop in output not attributable to weather is a clear indicator that your panels require cleaning.

Can I Safely Do This Myself?

This question is about safety and knowing your limits. Homeowners can and should perform basic visual checks from the ground—spotting debris, visible damage, or clearing leaves from a ground-mounted system are safe and prudent DIY tasks.

Critical Mistake to Avoid: The moment a ladder is required or you are tempted to touch any wiring, you must call a qualified, NABCEP-certified professional. The risk of a fall or a lethal shock from the DC system is severe. Attempting to save money on a service call is not worth risking your life or causing thousands in equipment damage.

What Are the Warning Signs That I Need a Pro?

Your system will provide clear signals when a serious issue is present. These red flags indicate problems that go beyond simple soiling.

- Nagging Inverter Faults: Recurring error codes are not to be ignored or simply reset. They signify a deeper electrical issue that requires expert diagnosis.

- Visible Physical Damage: Any sign of cracked glass, delamination (peeling layers), or burn marks on panels necessitates an immediate professional inspection.

- Exposed or Damaged Wiring: Frayed wiring, evidence of rodent damage, or conductors that have pulled loose are significant electrical and fire hazards. Do not touch anything and call for service immediately.

Will Skipping Maintenance Void My Solar Panel Warranty?

Yes, it absolutely can. Most major manufacturers, including Tier 1 brands like Sungrow or FranklinWH, have warranties that stipulate the equipment must be maintained according to their guidelines. Using a pressure washer or harsh chemicals can cause damage that is explicitly excluded from warranty coverage.

Furthermore, if a component fails due to neglect, the manufacturer can rightfully deny the warranty claim. Review your warranty documents and adhere to the specified maintenance protocols. Proper maintenance is not just about performance; it's about protecting your contractual rights as a system owner.

At Portlandia Electric Supply, we provide the Tier 1 modules, inverters, and Balance of System components that professionals trust to build and maintain high-performing solar assets. Our in-stock inventory and logistics support ensure you have what you need for new builds and O&M. Request a Bulk Quote for your next project and ensure your system is built to last.