Power Optimizer for Solar Panels: A Complete Guide for Installers & System Owners

Share

For solar installers, EPCs, and system owners, specifying the right technology is critical for maximizing project ROI, ensuring long-term performance, and meeting stringent U.S. safety codes. A power optimizer for solar panels is a crucial piece of module-level power electronics (MLPE) that solves one of the most common real-world performance killers: panel-level mismatch. By attaching directly to each solar panel, it ensures every module produces its absolute maximum power, regardless of shade, soiling, or manufacturing variances that hamstring traditional string inverter systems.

This guide provides a no-fluff, operational breakdown of how power optimizers work, where they deliver the most value, and how to integrate them correctly into your next project to drive superior energy harvest and code compliance.

What a Power Optimizer Does for Your Solar Project

The primary goal of any solar project is to maximize energy production and return on investment. However, field realities like partial shading from trees, soiling from dust, or minor panel-to-panel manufacturing differences can cripple a system's output. This is precisely the headache a power optimizer is built to cure.

In a traditional solar array using a standard string inverter, panels are wired in series. If one panel's output drops, the entire string suffers—a "weakest link" problem that can significantly reduce a system's lifetime energy yield.

Solving the Weakest Link Problem

Power optimizers are a type of Module-Level Power Electronic (MLPE) that breaks this dependency. By performing Maximum Power Point Tracking (MPPT) for each individual panel, they ensure one underperforming module no longer drags down its neighbors.

This is a game-changer for project stakeholders:

- For Installers & EPCs: It unlocks critical design flexibility. Complex roofs with multiple orientations or unavoidable shading are no longer dealbreakers. You can now design more powerful, compliant systems on challenging sites, opening up more project opportunities.

- For System Owners & Developers: It means more harvested energy and a faster payback period. The system becomes more resilient and productive, maximizing financial returns over its 25+ year lifespan.

Power Optimizer Benefits at a Glance

This table breaks down the core advantages of adding power optimizers to a solar project, highlighting the impact for both the professionals installing the system and the end customer who owns it.

| Benefit | Impact for Installers, EPCs & Homeowners |

|---|---|

| Increased Energy Harvest | Maximizes output from each panel, mitigating losses from shade or soiling for a better ROI. Data shows this can boost yield by up to 12%. |

| Greater Design Flexibility | Allows for installation on complex roofs with multiple orientations and string lengths without sacrificing performance. |

| Enhanced System Monitoring | Provides granular, panel-level data, making it easy to remotely pinpoint and diagnose underperforming modules, reducing truck rolls. |

| Improved Safety (NEC 690.12) | Automatically reduces DC voltage to a safe level during shutdown, ensuring compliance with rapid shutdown codes and protecting first responders. |

As you can see, the benefits go far beyond just a simple power boost. They enhance safety, simplify operations and maintenance (O&M), and make solar a viable option for a much wider range of properties. The market is taking notice, with projections showing the global solar power optimizer market is set to grow from USD 1.19 billion in 2024 to USD 2.8 billion by 2033. This growth is a direct response to the fact that nearly 30% of residential installations face performance issues that optimizers are specifically designed to solve. For a closer look at all the components that come together in a solar energy system, you can explore our comprehensive guide on solar panels.

How Power Optimizers Maximize Energy Harvest

To understand what a power optimizer for solar panels does, consider a traditional solar array as a garden hose with several kinks. The total water flow (energy) is limited by the worst kink (the weakest panel). A standard string inverter sees this entire "hose" as one unit, so if one section is pinched by shade or soiling, the output of the entire system plummets. This "weakest link" problem is a massive, often underestimated source of lost production.

Isolating Panels for Peak Performance

A power optimizer changes the game by giving each panel its own dedicated, perfectly-sized hose. At its core, an optimizer is a small DC-to-DC converter that performs Maximum Power Point Tracking (MPPT) at the module level. MPPT is the process of constantly fine-tuning the panel's electrical settings to extract the maximum power available at any given moment.

Instead of the main inverter guessing at a compromised "best" setting for the whole string, each optimizer finds the absolute perfect operating point for its specific panel, all day long.

Pro Tip for Installers: Module-level MPPT is your key to design freedom. You are no longer constrained by the weakest panel in a string, enabling you to tackle complex roof layouts, maximize panel density, and deliver more powerful systems for your clients.

The DC-to-DC Conversion Process

Once the optimizer finds that perfect power point, it performs its main job: DC-to-DC conversion. It takes the variable DC electricity from its panel and conditions it, adjusting the voltage and current before sending it to the central inverter.

This step accomplishes two critical things:

- Decoupled Performance: One panel's output no longer impacts the others. The optimizer on a shaded panel will adjust its output without holding back the fully sunlit panels next to it.

- Fixed String Voltage: All optimizers work together to feed the inverter a steady, fixed string voltage. This is a huge advantage because it allows the central inverter to operate in its most efficient "sweet spot" more consistently.

This combination of individual MPPT and smart DC-to-DC conversion allows an optimized system to harvest significantly more energy over its lifetime. It turns a rigid, all-or-nothing system into a flexible, resilient powerhouse where every panel contributes its absolute maximum.

Key Advantages for System Designers and Owners

When you specify a power optimizer for solar panels, you deliver tangible value to everyone in the project chain. These aren't just datasheet perks; they solve real-world headaches that appear on job sites and in performance reports.

Operational Wins for Installers and EPCs

For solar professionals, power optimizers are problem-solvers that streamline operations and open up more project opportunities.

- Unmatched Design Flexibility: The "weakest link" constraint is gone. Installers can design systems on complex roofs with multiple tilts, azimuths, and unavoidable shade without crippling array performance. This means more usable roof space and larger, more productive systems.

- Streamlined Troubleshooting: Panel-level monitoring is a game-changer for O&M. Technicians can remotely view the system's health and pinpoint the exact location of a fault from a laptop, slashing diagnostic time and eliminating unnecessary truck rolls.

- Simplified Safety Compliance: Power optimizers with rapid shutdown functionality are a core component for meeting NEC 690.12 requirements. When the system is de-energized, they automatically drop the DC voltage of each panel to a touch-safe level, protecting first responders and maintenance crews.

Expert Tip for Installers: Offering panel-level monitoring isn't just a feature; it's a powerful sales tool. It demonstrates transparency and gives clients a clear window into their investment's performance, building trust that leads to referrals.

Financial and Performance Gains for System Owners

For the homeowner or facility manager, the technical features of a power optimizer translate directly into financial gains and peace of mind.

Recent advances have fueled a 40% increase in the adoption of real-time monitoring from 2022 to 2024. By mitigating issues like shading and panel mismatch, a power optimizer for solar panels can increase total energy yield by up to 12%. This leads to better fault detection, a higher-performing system, and a faster ROI. You can explore the full research on these solar technology market trends.

This also future-proofs the investment. Years later, if a panel needs replacement, you won’t be stuck hunting for an exact, outdated model. An optimizer allows a new panel to integrate seamlessly without degrading the performance of the entire string, protecting the asset for the long haul.

Optimizers vs. Microinverters vs. String Inverters

Choosing the right inverter technology is a critical decision that shapes a project's cost, lifetime energy production, and reliability. Whether you're a procurement manager, system designer, or homeowner, understanding the trade-offs between power optimizers, microinverters, and traditional string inverters is essential.

A basic string inverter system offers the lowest upfront cost but comes with performance limitations, especially on roofs with partial shading. This is where Module-Level Power Electronics (MLPE) like a power optimizer for solar panels or a microinverter, provide a significant upgrade.

Core Technology Differences

- Power Optimizers (DC-Optimized System): These are smart DC-to-DC converters. Each one conditions power from a single panel before sending it to a central string inverter, which handles the final conversion to AC power. This provides panel-level optimization and monitoring while keeping the main inversion hardware in one accessible location. Leading brands include SolarEdge and Tigo Energy.

- Microinverters: These units perform the entire DC-to-AC conversion on the roof, attached to each panel. This creates a fully distributed system with no central inverter, offering maximum modularity.

- String Inverters: This traditional technology treats a group of panels ("string") as a single unit, making it vulnerable to the "weakest link" problem where one shaded panel reduces the output of the entire string.

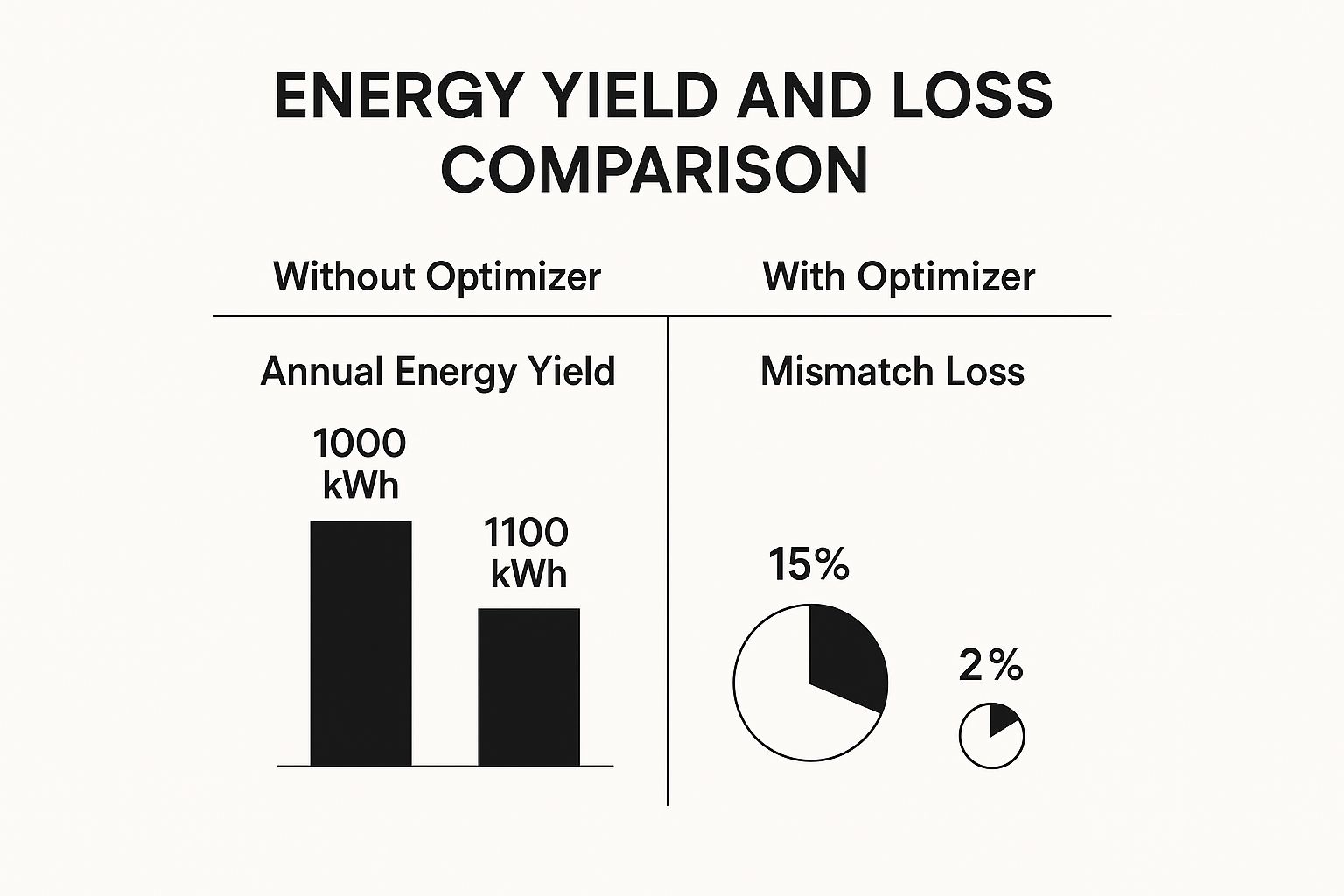

The data shows that managing each panel individually can dramatically increase annual energy production and virtually eliminate losses from panel mismatch.

Technology Showdown for Your Next Solar Project

This head-to-head comparison breaks down how each technology stacks up across the criteria that matter most for your next project or procurement decision. For an even deeper look, explore our complete guide to solar inverters.

| Feature | Power Optimizers | Microinverters | String Inverters |

|---|---|---|---|

| Performance in Shade | Excellent. Isolates shaded panels so they don't affect others. | Excellent. Each panel is independent. | Poor. One shaded panel can reduce the output of the entire string. |

| System Efficiency | High. Central inverter operates at peak efficiency with fixed voltage. | High. Panel-level optimization, but more components on the roof. | Moderate. Efficiency drops when panels are mismatched or shaded. |

| Monitoring Granularity | Panel-level. Detailed data for troubleshooting and performance tracking. | Panel-level. Provides comprehensive data for each individual module. | String-level only. Cannot identify individual underperforming panels. |

| Upfront Cost | Mid-range. More expensive than string but often cheaper than microinverters. | Highest. More hardware and complexity drives up the initial cost. | Lowest. Simplest technology with the most attractive upfront price. |

| Reliability & Maintenance | High. Fewer complex electronics on the roof. Central inverter is easy to access/service. | Good. No single point of failure, but more components on the roof can mean more potential service points. | Good. Mature technology, but a single inverter failure takes the whole system offline. |

| Safety Compliance (NEC 690.12) | Excellent. Integrated rapid shutdown meets NEC safety standards automatically. | Excellent. Low-voltage AC on the roof and inherent rapid shutdown capabilities. | Requires additional hardware to meet modern rapid shutdown codes. |

The right choice depends on your project's priorities: lowest initial cost (string), maximum modularity (microinverter), or a powerful blend of panel-level optimization and centralized serviceability (power optimizer).

Integrating Power Optimizers into Your System Design

Successfully integrating a power optimizer for solar panels into a project requires a smart design strategy that ensures all components work in harmony. Getting this right from the start is key to preventing costly field mistakes and ensuring the system delivers on its performance promises.

The process begins with equipment selection. It is absolutely critical to confirm that your chosen optimizer is fully compatible with the inverter—whether you're using a native ecosystem like SolarEdge or a third-party inverter that’s enabled for use with a brand like Tigo. You must also check the optimizer’s electrical specs against the solar panel's datasheet, ensuring the maximum input voltage, current, and power ratings align.

System Design and String Sizing

While optimizers provide incredible flexibility, they do not eliminate the rules of proper string sizing. You must operate within the inverter's input window and adhere to manufacturer guidelines.

- String Length: Always follow the manufacturer's design rules for the minimum and maximum number of panels (and their optimizers) per string.

- Communication: Properly place the communication gateway or unit to enable panel-level monitoring and critical rapid shutdown functions.

- Layout Planning: Meticulously map out where each optimizer will go and its wiring path to save time and prevent errors on the job site.

Critical Mistake to Avoid: A common field error is mixing different optimizer models or panels with significantly different electrical characteristics on the same string without consulting manufacturer guidelines. This is a recipe for communication errors, underperformance, and system faults.

A Practical Design Checklist for Installers

This step-by-step checklist provides a framework for a smooth, compliant installation.

- Verify Optimizer-Inverter Compatibility: Double-check that the optimizer model is certified to work with your specific inverter brand and model (e.g., SolarEdge, Tigo with a compatible inverter).

- Match Optimizer to Panel Specs: Cross-reference the optimizer's max voltage (Voc), current (Isc), and power (Pmax) ratings with the PV module's datasheet.

- Adhere to String Sizing Rules: Use the manufacturer's design tool or official guidelines to calculate the correct number of modules per string for your specific site conditions.

- Integrate Monitoring & Communications: Plan the physical layout for the communication gateway and ensure it has a clear connection path to every optimizer.

- Plan for Rapid Shutdown Compliance: Confirm your design meets all NEC 690.12 requirements. This is non-negotiable for safety.

Partnering with a reliable supplier like Portlandia Electric Supply is a major asset. With our in-stock inventory of leading brands like SolarEdge and Tigo, bundled logistics, and NABCEP-certified design review, we can help validate your system design and ensure you have the right components for a high-performing, compliant job. For more insights, see our guide to comprehensive solar energy solutions.

Common Questions About Solar Power Optimizers