A Project Manager's Guide to EV Charging Station Installation Costs

Share

Planning an EV charger installation? Your first question is the most critical: "What will this actually cost?" Whether you're a homeowner, installer, or commercial developer, understanding the budget is non-negotiable for project success.

For homeowners, a typical Level 2 charger installation ranges from $549 to $1,379, but this can climb if your electrical panel needs a major upgrade. For EPCs and commercial developers, the stakes are much higher. A basic commercial Level 2 station can cost several thousand dollars per unit, while a high-powered DC fast charger project can easily surpass $100,000 once site work and utility upgrades are factored in.

This guide provides a no-nonsense breakdown of the real-world costs for both residential and commercial projects. It’s designed for installers needing to quote accurately, homeowners planning a budget, and developers evaluating project ROI. We’ll cover hardware, labor, hidden costs, and the critical steps for navigating permits and incentives to ensure your project is delivered on time and on budget.

Understanding the True Cost of EV Charger Installation

Calculating the final cost for an EV charging station installation requires a detailed project-level view. The charger itself is just one line item. You must also account for skilled labor, electrical materials, permitting, and potentially significant site preparation or utility upgrades.

- For Homeowners: The goal is convenient, reliable overnight charging. The key variables are your home's existing electrical capacity and the distance from your panel to the garage.

- For Installers & EPCs: You need to deliver a safe, code-compliant, and profitable project. This means accurately scoping all labor, materials, and potential site-specific challenges—from panel upgrades to trenching—to create a winning bid.

- For Developers & Facility Managers: Your focus is on ROI, scalability, and compliance. The budget must cover commercial-grade hardware, extensive site work, and navigating complex utility interconnection agreements.

Most homeowners install a Level 2 charger, which offers the best balance of charging speed and installation cost. However, the final price tag is determined entirely by the specifics of your property.

Key Cost Drivers for Home Installations

The single biggest factor influencing the final bill is the installation's complexity. A simple installation in a garage with a modern, accessible electrical panel will be on the lower end of the cost spectrum. Conversely, if the panel is in the basement on the opposite side of the house, the labor and material costs for running the new circuit will increase significantly.

On average, homeowners spend about $964 for a professional installation. A straightforward job can be as low as $500 to $1,000. However, if complications arise—like needing to trench conduit to a detached garage or requiring a full electrical panel upgrade—the cost can quickly jump to $2,500 or more. Labor for a certified electrician alone typically falls between $400 and $1,200. You can explore more detailed cost breakdowns for specific scenarios.

To provide a clear budgeting framework, here’s a breakdown of what a typical residential installation involves.

Typical Residential EV Charger Installation Cost Breakdown

This table outlines the common expenses for a standard Level 2 EV charger installation. These are estimates; your actual costs will depend on your specific equipment, property layout, and local labor rates.

| Cost Component | Typical Price Range (USD) | Notes for Budgeting |

|---|---|---|

| Level 2 EV Charger (Hardware) | $300 – $700+ | Choose a UL-listed charger that matches your vehicle's max charge rate. |

| Electrician Labor | $400 – $1,200 | Covers assessment, running a new dedicated circuit, and final connection. |

| Electrical Materials | $200 – $500 | Includes copper wiring, conduit, a new 240V breaker, and outlet. |

| Permit Fees | $50 – $250 | Varies by municipality; required for code compliance and safety. |

| Hidden Cost: Panel Upgrade | $1,500 – $4,000+ | Required if your current panel is undersized or lacks space. |

| Hidden Cost: Trenching/Repairs | $500 – $1,500+ | Needed if running conduit underground or through finished walls. |

As shown, the "hidden" or site-specific costs can dramatically increase the total project budget.

Budgeting for Commercial and Public Stations

When scaling from a residential garage to a commercial site, the budget and complexity increase exponentially. For EPCs and developers, financial planning is far more rigorous. You're not just procuring more powerful (and more expensive) chargers from brands like Sungrow or Cummins; you're investing heavily in site engineering and construction.

This typically includes:

- Hardware: Sourcing commercial-grade Level 2 or DC fast chargers built for high-throughput and network connectivity.

- Site Preparation: Budgeting for trenching, concrete pads, protective steel bollards, lighting, and ADA-compliant access.

- Electrical Infrastructure: This is often the largest cost, involving potential upgrades to service transformers, switchgear, and utility feeds to handle the massive power demands.

Expert Tip for Procurement Managers: At Portlandia Electric Supply, we help commercial clients streamline procurement and manage these complex project costs. Our PowerLink network connects you with qualified local installation pros, ensuring your project is completed to code and on budget.

Decoding Home EV Charger Installation Costs

To accurately budget the ev charging station installation cost for a home, you must move beyond online averages and break the project down into its core components. Getting this right from the start is crucial for both homeowners and installers to ensure a smooth, surprise-free process.

The final price is a sum of the charger hardware, professional labor, materials, permits, and any necessary electrical upgrades specific to the home. While a basic Level 1 charger that plugs into a standard wall outlet is an option, its slow charging speed makes it impractical for most EV owners. That's why the industry standard is a Level 2 charger from trusted brands like Cummins or FranklinWH, which typically costs between $300 and over $700 for the unit alone.

Essential Installation Components

Once you've selected a charger, the largest portion of your budget will be dedicated to professional installation.

Critical Safety Warning: Hiring a certified electrician is non-negotiable. This is a high-voltage project that requires adherence to the National Electrical Code (NEC) to ensure safety and prevent fire hazards.

Here’s a breakdown of what a professional installation entails:

- Hiring a Certified Electrician: Labor costs typically range from $400 to $1,200. This covers the electrician's time to perform a load calculation, install a new dedicated 240V circuit, and safely connect the charging station.

- Materials: This includes all necessary components beyond the charger itself, such as the proper gauge copper wiring, protective conduit, and a new double-pole circuit breaker. These materials can add $200 to $500 to the total cost.

- Permitting: Most jurisdictions require an electrical permit for this type of installation to ensure the work is performed to code and inspected. Permit fees vary widely by location, typically costing $50 to $250.

Pro Tip for Homeowners: Always get at least three quotes from licensed and insured electricians. This helps you compare not just price, but also their proposed scope of work, ensuring no critical steps are overlooked.

Uncovering Hidden Costs

A common reason for unexpectedly high quotes is the need for electrical system upgrades. These are not "hidden" costs so much as site-specific requirements that can only be identified after a professional assessment.

Here are the most common project scope additions:

- Electrical Panel Upgrade: This is the most significant potential cost. If your home has an older panel (rated for less than 200 amps) or lacks physical space for a new 240V breaker, an upgrade is necessary. This is a major job that can cost between $1,500 and $4,000.

- Trenching or Drywall Repair: If the charger is located far from the electrical panel, the electrician may need to dig a trench for outdoor conduit or cut into finished walls to run wiring. This adds labor and subsequent repair costs to the project.

For a clear estimate, engage with professional residential EV charger installation services who can assess your specific situation. For more insights on EV ownership, explore our complete guide to electric vehicle topics.

Analyzing Commercial EV Charging Station Costs

For Engineering, Procurement, and Construction (EPC) firms, project developers, and facility managers, the EV charging station installation cost for a commercial site is a completely different animal. We’re not talking about a simple garage setup anymore. We're stepping up to multi-unit properties, public lots, and fleet depots, where the financial and logistical hurdles grow exponentially.

The investment for commercial-grade infrastructure goes far beyond just buying the hardware. While a home install might just need a dedicated circuit, a commercial project demands a full-blown site strategy. This means deploying heavy-duty Level 2 AC chargers or high-power DC fast chargers from brands like Sungrow, which are built to handle constant public use and integrate with payment systems.

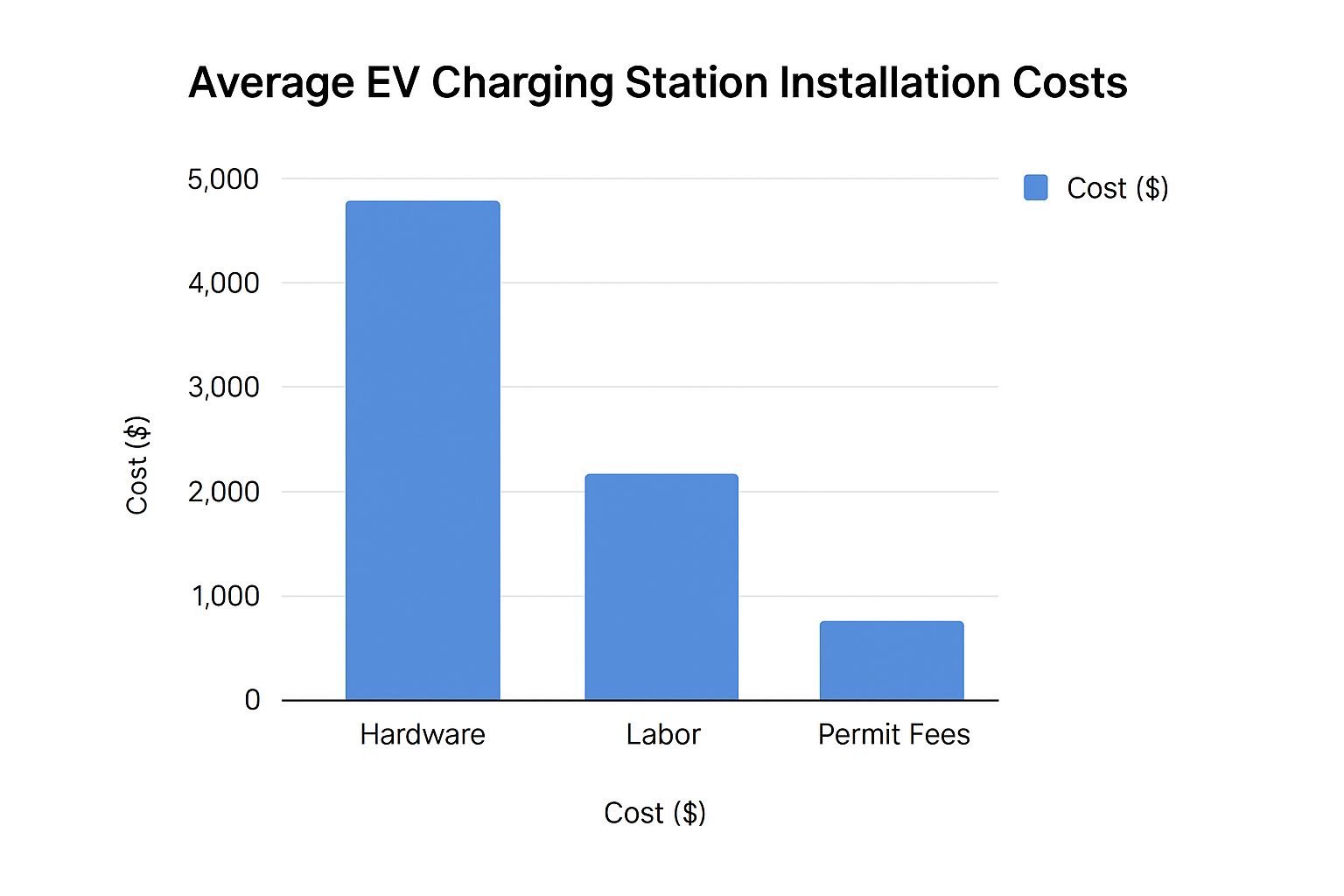

This image really drives home the point: hardware is just one piece of the financial puzzle. As the data shows, it's often the labor and site preparation that take up a huge slice of the project's budget.

Core Cost Components for Commercial Projects

When you break it down, the total project cost is a mix of three big things: the chargers themselves, the site work, and the electrical upgrades. The balance between these can shift dramatically depending on what you're building and what you’re starting with.

- Equipment Costs: Commercial Level 2 chargers are built tougher and have more features than their residential cousins. DC fast chargers? They're in a league of their own. A single 50 kW DC fast charger can run you around $45,000, and that price can jump to $65,000 for a powerful 350 kW unit—and that’s before a single shovel hits the ground.

- Site Preparation: This is where budgets can get blown out of the water. We're talking about all the civil work—trenching for conduits, pouring concrete pads for the chargers, installing protective bollards, and making sure everything is ADA compliant.

- Electrical Infrastructure: This is frequently the biggest and most unpredictable expense. To power a bank of DC fast chargers, a site might need a brand-new, dedicated transformer, upgraded switchgear, and even new distribution lines from the utility company. These upgrades are absolutely critical for handling the massive power draw, but they add serious cost and complexity.

Commercial EV Charger Cost Comparison Per Unit

To give you a clearer picture, let's look at how the costs stack up for different types of commercial chargers. The numbers below represent the all-in estimated cost per charger, including equipment, labor, and basic site prep. Notice how quickly the investment climbs with the power output.

| Charger Type | Power Output | Estimated All-In Installation Cost (Per Charger) | Key Considerations for Developers |

|---|---|---|---|

| Level 2 AC Charger | 7-19 kW | $6,000 – $15,000 | Ideal for workplaces, MUDs, and locations with long dwell times. |

| DC Fast Charger | 50-150 kW | $40,000 – $100,000 | Best for public charging, retail corridors, and fleet depots needing quick turnover. |

| High-Power DC Fast Charger | 150-350+ kW | $100,000 – $200,000+ | Required for highway corridors and next-gen EVs; involves significant utility upgrades. |

As you can see, the leap from a standard Level 2 unit to even a basic DC fast charger is substantial. For EPCs and developers, this underscores the importance of right-sizing the infrastructure to meet real-world demand without overspending.

For businesses looking at these numbers, remember that this investment often aligns with bigger corporate sustainability goals. To keep everything on track, a decarbonization platform can be a great tool for measuring the real environmental impact of your new EV charging infrastructure.

Real-World Cost Scenarios

Location matters. In California, for example, labor costs alone can run from $1,490 to $2,470 per charger, and that figure changes based on the scale of the job. Once you add in the equipment, site work, and heavy-duty electrical upgrades for high-power units, the total adds up fast.

These commercial EV projects often run parallel to other large-scale energy initiatives. For a deeper look at managing these kinds of major project expenses, you might want to check out our guide on commercial solar installation costs.

Working with a distributor like Portlandia Electric Supply means you get more than just hardware. You get a partner who can help with compliance support and logistics management to make sure your procurement process is as smooth and cost-effective as possible, no matter the project size.

Navigating Permits And Utility Coordination

You’ve got the hardware picked out and the site is ready to go. But now comes the part that trips up even seasoned developers: the paperwork. Navigating the maze of permits, codes, and utility company requirements can easily bring a project to a grinding halt, adding serious time and money to your ev charging station installation cost.

For installers and commercial property owners, this is where having your ducks in a row really matters. It's not just about getting a piece of paper signed. It's about making sure your entire setup is safe, compliant with local rules, and legally tied into the grid. Trying to cut corners here is a surefire way to fail inspections and face expensive rework.

The Permitting and Code Compliance Process

Before a single shovel hits the ground, you'll almost certainly need an electrical permit. This is the city’s way of ensuring your project follows strict safety standards, which are largely based on the National Electrical Code (NEC). The NEC is the bible for safe electrical work, and it's what the local inspector will have in hand when they show up.

On top of that, every piece of equipment—from the charger itself to the wiring and conduits—must be UL-listed. This mark from Underwriters Laboratories means the product has passed tough safety tests. Using non-listed gear is a huge red flag and a quick way to get your project shut down on the spot.

Critical Compliance Note: For any project, and especially for commercial installations, knowing the latest NEC and UL standards inside and out is non-negotiable. Partnering with someone who provides solid compliance support is one of the best ways to de-risk your project and sail through inspections.

Coordinating with the Local Utility

For a single charger at a home, dealing with the utility might be pretty straightforward. But for a business putting in a bank of Level 2 chargers or even one DC fast charger, it's a whole different ballgame. You're not just plugging something in; you’re establishing a new service and will likely need a formal utility interconnection agreement.

Here’s what that typically involves:

- Submitting Plans: The utility needs to see your electrical drawings to understand how your project will affect their grid.

- Load Calculations: They'll run the numbers on your total power demand to make sure the local lines can handle the new load.

- Potential Upgrades: If the grid can't handle it, the utility might require you to pay for expensive upgrades like new transformers or power lines. These "make-ready" costs fall on the project owner and can dramatically increase the total budget.

Getting the green light from a utility can take anywhere from a few weeks to several months. That’s why you have to start this conversation early. A delay here creates a domino effect, pushing back your entire construction schedule.

This is exactly where Portlandia Electric Supply comes in. We do more than just sell equipment. We bring deep compliance expertise to the table and can connect you with trusted local pros through our PowerLink network. This ensures your project is handled by experts who know the local codes and already have relationships with the utility companies, helping you avoid costly mistakes and keep things moving forward.

How To Reduce Your EV Charging Installation Costs

The sticker shock on an EV charging station installation cost can feel daunting, but don't let that initial number scare you off. With a bit of smart planning, you can bring that figure down to a much more manageable level, whether you're a homeowner or a commercial developer.

The biggest lever you can pull comes from government and utility incentives. These programs exist for a reason: to make the switch to electric more accessible by taking some of the financial sting out of the installation.

Leverage Every Available Incentive

Before you do anything else, your first step should be a deep dive into the available financial incentives. Hunting these down can slash your upfront costs dramatically.

- Federal Tax Credits: The Alternative Fuel Vehicle Refueling Property Credit is a big one. For home installations, it provides a federal tax credit of 30% of the cost, up to $1,000. Commercial projects can tap into similar, often more substantial, credits.

- State & Local Rebates: Many states and cities have their own programs. Initiatives from authorities like NYSERDA in New York or various programs across California can put hundreds, sometimes thousands, of dollars right back into your pocket.

- Utility Programs: Don’t forget to check with your local electric company. Many offer their own rebates for buying and installing specific chargers. Hawaiian Electric's Charge Up Commercial program, for example, can cover the entire installation cost for businesses that qualify.

Smart Planning for Commercial Projects

For EPCs and developers, this is where the real savings happen. Thinking ahead isn't just a good idea; it's how you prevent costly rework and get the most out of your investment from day one.

A classic rookie mistake is poor charger placement. The solution is smart site selection. Picking a spot for your chargers that's close to your existing electrical infrastructure might seem obvious, but it can save you thousands in trenching and conduit costs alone.

Another pro move is to plan for the future. It is far, far cheaper to install the underground conduit for ten charging stations today—even if you're only hooking up five right now—than it is to tear up the asphalt again in two years. This is all about playing the long game, future-proofing your site and taking advantage of economies of scale.

Expert Tip for Developers: Bundle your procurement. Sourcing all your chargers, switchgear, and balance-of-system components from a single distributor like Portlandia Electric Supply simplifies logistics and unlocks bulk pricing, directly lowering your total material spend.

Cost-Saving Tips for Homeowners

Homeowners have plenty of opportunities to keep their installation costs in check, too. The single most important thing you can do is avoid over-speccing your charger. Sure, a 48-amp charger sounds powerful, but if your car can only accept 32 amps, you're just paying for performance you can't use. Match the charger to your vehicle's real-world needs.

It's also worth thinking about timing. Try scheduling your installation during an electrician's off-season, which is usually late fall or winter. With a lighter schedule, some contractors might offer more competitive rates for their labor.

By mixing and matching these strategies, you can make your EV charger installation a whole lot more budget-friendly. For more tips on optimizing your energy projects, feel free to check out our other guides in our energy solutions blog.

Your Top Questions About EV Charger Installation Costs

Even after breaking down the numbers, it's natural to have more questions about the specifics of an EV charging station installation cost. These are some of the most common ones we get from homeowners and project managers alike. Let's dig in and get you some clear, practical answers.

Is a Level 2 Charger Really Worth the Extra Cost?

For almost every EV driver, the answer is an emphatic "yes." It's tempting to try and get by with a Level 1 charger that plugs into a standard wall outlet, but the reality is they are painfully slow. You're looking at adding just 3-5 miles of range per hour. That's not going to cut it for most daily driving.

A professionally installed Level 2 charger completely changes the game, delivering a solid 25-60 miles of range per hour. It effectively turns your garage into your own private gas station, letting you fully recharge overnight, every night. Think of the higher upfront cost as an investment in daily convenience—one that pays you back every time you plug in.

How Can I Tell If My Electrical Panel Needs an Upgrade?

This is a big one, and the only person who can give you a definitive answer is a qualified electrician. They’ll perform what’s called a "load calculation" to see if your home's existing panel can safely handle the sustained power draw of an EV charger.

That said, you can spot a few potential red flags yourself:

- Your main panel is rated for less than 200 amps.

- You look inside and see no empty slots for a new double-pole breaker.

- Your home already runs other power-hungry appliances, like a tankless water heater or a hot tub.

If you check any of these boxes, it's smart to budget for a panel upgrade. It’s a common part of the process and typically adds $1,500 to $4,000 to the total project cost.

For a Commercial EV Project, What's the Biggest Cost?

Here's something that surprises a lot of first-time developers: for commercial and public charging stations, the single biggest cost isn't the charging hardware. It’s the site preparation and utility infrastructure.

Things like trenching long distances to bring in power, pouring new concrete pads for the chargers, and installing protective steel bollards all add up. The real budget-buster, though, can be paying for major utility-side upgrades like a new transformer. These ground-level costs can easily eclipse the price of the chargers themselves, which is why a thorough site assessment is non-negotiable for an accurate bid.

Critical Safety Warning: Never, under any circumstances, attempt to install an EV charger yourself to save a few bucks. This is high-voltage work that demands a licensed professional. A DIY installation isn't just incredibly dangerous—posing a real risk of fire and electric shock—it will also void your equipment warranty, disqualify you from any rebates, and almost certainly violate local building codes.

Working with an expert distributor from the get-go ensures your project is planned correctly. Portlandia Electric Supply provides the right equipment, helps you navigate compliance, and connects you with vetted installers to make sure your project is safe, on-budget, and built for the long haul.